Mechanical joining processes can be used to join a wide range of materials quickly and reliably. Blind riveting technology has the additional advantage of only requiring one-sided access. With GESIPA®’s range of threaded fasteners, blind rivet nuts, and blind rivet studs, high-quality load-bearing threads can be driven into thin, soft or sensitive materials without placing any additional stresses on whatever is being joined.

This includes applications where other production processes such as threading, conventional screw fitting and welding are unfeasible. Other advantages of this joining method are one-sided access, flexible, easy assembly and in many cases, enhanced mechanical properties. This means that in almost any material, it can produce load-bearing assembly points that also provide a sturdy basis for non-permanent screw connections.

Because the joining element is customised – based on material, geometry or surface coating – mechanical properties can be optimised for any application.

Savings of up to 50%

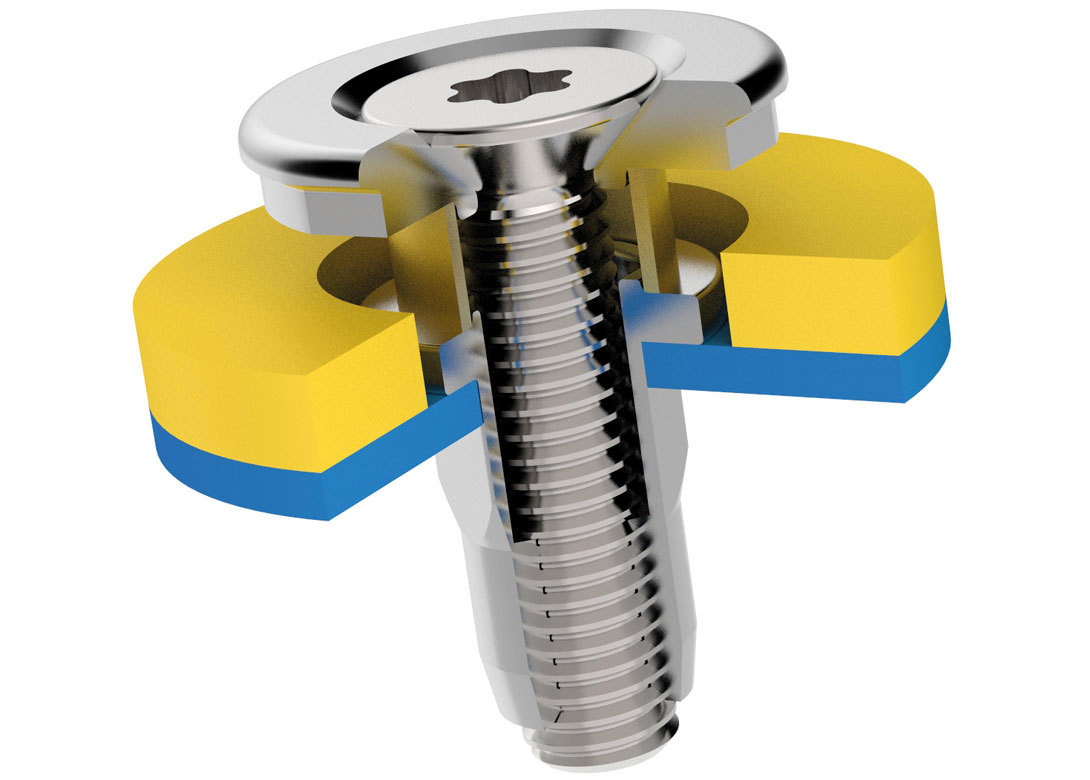

The patented GESIPA® G-Fast System combines a blind rivet nut and bolt in a single joining element. This combination makes it possible to drive a high-quality thread into thin material while securing a component at the same time. As a result, the user can dispense with an entire process step, as well as an assembly site, processing tools and associated processes.

The method only requires access from one side – perfect for those hard to reach locations. The resulting screw connections are also non-permanent – an invaluable advantage compared to other mechanical joining methods. The GESIPA G-Fast System offers a high-level of flexibility in production process design, as well as cost-effective synchronised mass production involving special requirements. GESIPA reports that integrating the bolting process into riveting can save up to 50% of assembly time.

Fast, simple, efficient processing

The GESIPA G-Fast System uses conventional bolt drivers already employed on assembly lines. All the user needs is an adapter customised for the joining element and the application. Because it uses manual bolt drivers and customisable joining elements, the G-Fast System can be used anywhere that non-permanent connections are required in short assembly processes.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.