As composite materials grow both in range and volume of applications, the challenge to find the right fastening solution continues to grow. Here, Matthew Stevens, managing director at bigHead® Bonding Fasteners Ltd (a Bossard company), explores some trusted fastening solutions within this fast growing market.

What is a composite

Composites are materials engineered from two or more constituent materials with different physical or chemical properties. The two main categories of constituent materials making up the composite are the matrix and the reinforcement. Examples of matrices are resins, ceramics, polymers or cements, with examples of reinforcements including fibres, sandwich cores or aggregate. The matrix material surrounds and supports the reinforcement material and the reinforcement material imparts its special mechanical and physical properties to enhance the matrix properties.

Composite materials are formed into a shape during their manufacture, typically in a mould cavity or on a mould surface. The synergy between the two materials results in a composite material with properties unavailable from the individual constituent materials. The wide variety of matrix materials that are available provide engineers with significant design freedom and greater potential to optimise their product’s form and function.

The ability to combine different constituent materials to create superior new composite materials allows engineers to target improvements in cost, weight, strength and handling as their product applications and manufacturing processes demand.

The growth of composites

The development of composites and plastics and their migration into applications habitually dominated by traditional materials such as wood and metal is a significant trend. Lighter, stronger, versatile and more mechanically stable, modern composite materials have found a home in almost every industrial sector. The issue of reducing weight or ‘lightweighting’ has become central to innovation in the automotive sector, accentuated by high oil prices and regulatory pressure to reduce carbon emissions.

Initially, lightweight composite materials such as carbon fibre were only used in very high-end applications such as aerospace and super cars, as costs were very high and production processes slow. Increasingly, major car makers are introducing carbon fibre into their luxury models and many are examining ways to replace structural elements traditionally made in heavier metal. As the volumes of carbon fibre production increases, the costs will fall and the number of applications in premium and standard car models will increase.

The fastening challenge in composites

The expansion of lightweight composite materials presents challenges as well as opportunities. One of the key challenges is how to securely fasten to such materials. Traditional fastening systems designed for sheet metal, such as rivets, bolts and clinched fixings are often incompatible with composites or require too many compromises to work. For example, weld studs designed for metal cannot be effectively welded to plastic.

Lightweight panel composites need to be kept thin and not thickened to hold a traditional fastener in position. Thin carbon panels do not improve with piercing or drilling. In short, design and process engineers liberated by composite materials do not want to be limited by fastening solutions that are not designed for use with composites.

Fasteners embedded in composites

Embedding fasteners in composites is a common requirement and can provide a secure and discrete fastening solution. Integrated into the composite manufacturing process the fasteners become integral to the composite product, which supports efficient final assembly. The embedded fasteners can be integrated within the composite mould tool, there is no secondary work required, and the fastener is fully integrated in the composite product – making it very discrete and stable.

Embedding fasteners in composites is a common requirement and can provide a secure and discrete fastening solution. Integrated into the composite manufacturing process the fasteners become integral to the composite product, which supports efficient final assembly. The embedded fasteners can be integrated within the composite mould tool, there is no secondary work required, and the fastener is fully integrated in the composite product – making it very discrete and stable.

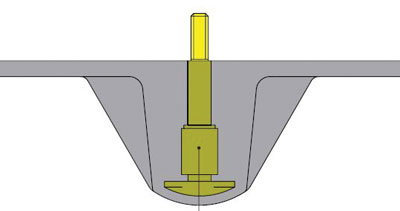

However, embedding a fastener that has not been designed to be embedded can lead to design compromises and process inefficiencies. These compromises can weaken the composite product or increase its thickness and weight. The example above shows how plastic is built up on this floor pan around a traditional bolt for no other reason than to hold it securely in position.

Seen in cross section you can see how the traditional bolt requires significant composite material to anchor it securely in position.

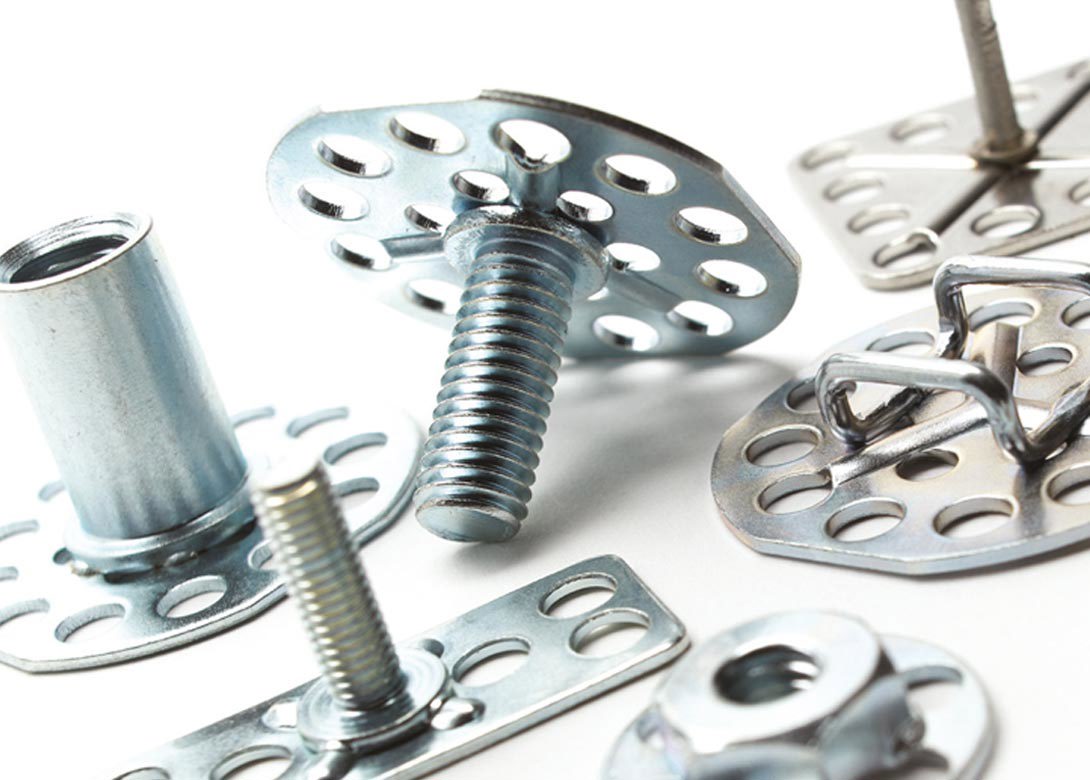

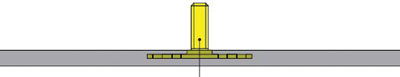

Alternatively, a bonding fastener such as a bigHead® can be used, which is designed to be embedded in the composite material without the need for the material to be thickened. The thin flat head which is perforated to allow the flow of composite material, helps transfer the load efficiently into the composite structure. The same threaded stud fastening is provided with potentially higher tensile and torsional strengths. Different levels of tensile and torsional strengths can be achieved by using different size and shape heads.

In summary, these are some of the key benefits of using a fastener designed to be embedded in composites:

Space saving, as no additional composite material needs to be built up to anchor the bolt.

- Weight saving, as less composite material is used.

- Reduced composite curing times, as less composite material is used.

- Higher tensile and torsional loads can be withstood with bigHead designs.

- Design optimisation with the fastener designed around the composite product.

Surface bonding on composites

Many composite applications rely on the use of thin structures – carbon fibre reinforced plastics used for automotive body panels are a good example of this. Such composite panels are often only a few millimetres thick.

Many composite applications rely on the use of thin structures – carbon fibre reinforced plastics used for automotive body panels are a good example of this. Such composite panels are often only a few millimetres thick.

In these cases, without sufficient material to embed a fastener, a surface bonded fastener can be a very effective and discrete solution. Bonded to the surface with adhesive, a bonding fastener can provide a secure fixing that does not pierce or damage the composite panel.

The example to the left shows a carbon fibre diffuser for a car, attached with bigHead bonding fasteners. Discrete and very strong, the bigHead fasteners are surface bonded on the inside of the diffuser with a structural adhesive. This bonded solution is completely invisible from the ‘A-side’ as there are no rivets, drill holes or visible ‘shadows’. The structural integrity of the single composite panel is fully maintained. Due to the unique design of the perforated ‘head’, the glue flows through the holes and locks the fastener into position, achieving high stability and strength. Bonded in position by the Tier 1 supplier, the diffuser is ready for final assembly at the OEM.

Depending on the application, various bonding fastener designs are possible to compliment rather than compromise the final design and function of the composite part.

Alternative fasteners requiring a hole to be drilled or pierced through the panel can weaken the panel. Piercing a carbon fibre reinforced panel will break or damage the reinforcing carbon fibres which are, by definition, there to provide reinforcement and structural integrity. Depending on the position, size and quantity, the holes in the panel may lead to degradation and failure of the composite under stress. Composites can fail on the microscopic or macroscopic scale. Compression failures can occur at both the macro scale or at each individual reinforcing fibre in compression buckling. Tension failures can be net section failures of the part or degradation of the composite at a microscopic scale where one or more of the layers in the composite fail in tension of the matrix or failure of the bond between the matrix and fibres. Due to the complexity and variation of composite materials it would therefore be necessary to include the piercing or drilling of holes into any pre-construction strength testing and analysis of the behaviour of a composite panel so fastened.

The surface bonded solution does rely on the adhesive for the critical bond between composite structure and fastener. The performance and reliability of adhesives has continued to grow and they are now commonly used and relied upon in numerous applications. The range of adhesives is very large, but almost any structural adhesive will be compatible with a bonding fastener such as the bigHead. There is also a significant range of adhesive curing speeds available on the market, from several seconds to hours, to ensure compatibility with the assembly process. Much work is also being done on the efficiency of adhesive delivery, from hand-held devices to fully automated robot cells.

It is no longer necessary for design engineers working in composites to compromise their product design or function by using fasteners designed for non-composite applications. In doing so, they risk their product quality and customer satisfaction.

Excellent fastening solutions designed for composites, offering design flexibility and functional reliability, have become well established over many years in applications across a wide range of industries. The quality of these solutions has been fully tested by world leading companies in the automotive, marine, construction, energy and general manufacturing industries. To find out how these tried and tested solutions can work for you, and to receive assistance in optimising your composite fastening solution, contact Bossard.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.