Adding to its broad portfolio of thermal interface material solutions (TIM), Henkel has recently announced the commercial availability of its new adhesive, Bergquist Hi Flow THF 5000UT, which demonstrates robust thermal performance.

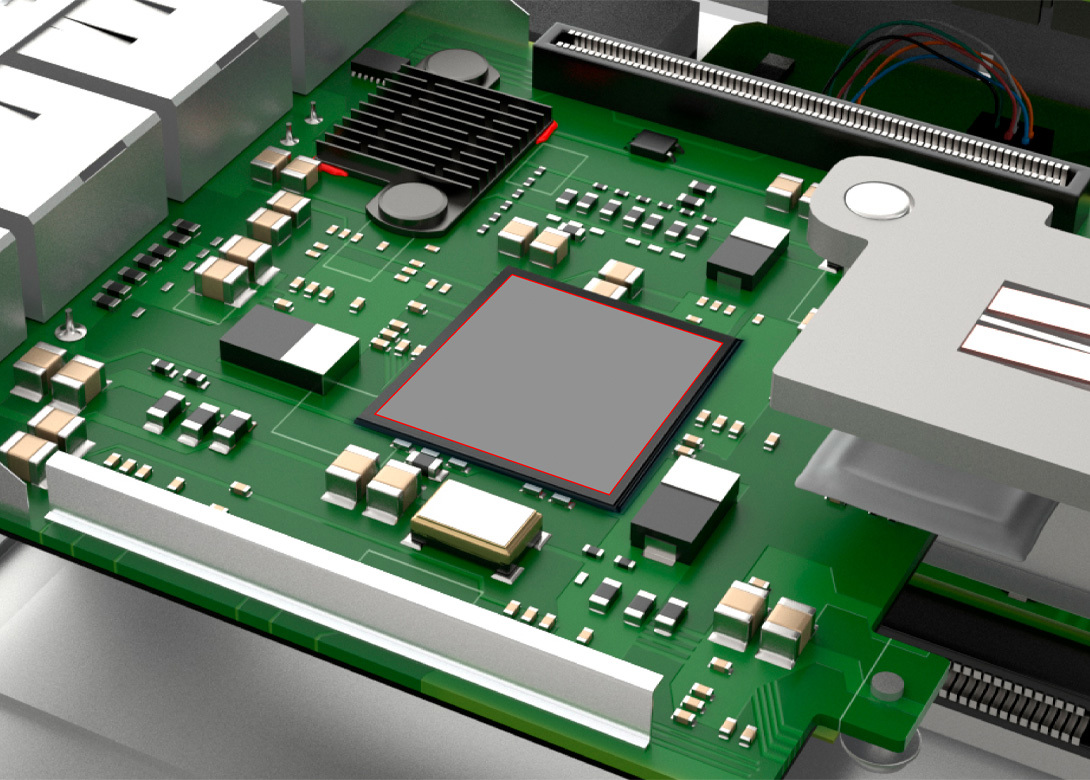

The phase change film TIM allows for low mechanical pressure to be achieved thorough wet out and an ultra-thin bond line at the interface. This is critical for challenging package designs with complex architectures, such as lidless multi-chip devices used in high-performance electronic and industrial applications.

Bergquist Hi Flow THF 5000UT demonstrates low thermal impedance across various bond line thicknesses at both ultra-low and higher pressure. Henkel also states it delivers good reliability as evaluated up to 150°C and achieves thermal conductivity as high as 8.5 W/m-K.

“Bergquist Hi Flow THF 5000UT is one of the market’s best performing thin bond line phase change TIMs at low pressure. Reduced mechanical pressure is essential to avoid stress-induced defects on certain devices that integrate large, thin, delicate die. And notably, even lower thermal resistance can be achieved with slightly higher pressure, if desired. The versatility is exceptional,” says Wayne Eng, data & telecom global head of market strategy, Henkel.

In addition to strong thermal performance, Bergquist Hi Flow THF 5000UT enables easy application and simple final assembly. The film medium allows heat sink manufacturers to apply the phase change TIM before shipment. During assembly, attaching the heat sink to the heat-producing component is easy, providing a clean alternative to greases and other liquid-based TIMs. Moreover, Henkel states the adhesive does not require pre-burn before use. Once the assembled parts are heated to the phase change temperature of 45°C, the material flows into the bond line, immediately providing heat dissipation.

“Leading data centre innovators have already embraced Bergquist Hi Flow THF 5000UT, as it enables space-saving, low-stress, high thermal performance for switches and routers with higher-power processors,” explained Wayne. “The data centre space is one of the most demanding in terms of thermal management requirements and has been a good testing ground for this novel phase change material, which met or exceeded challenging metrics. Bergquist Hi Flow THF 5000UT’s robust performance is an excellent solution for any high-power application – industrial and automotive, for example – that requires a low thermal impedance, high-reliability thin bond line TIM.”

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.