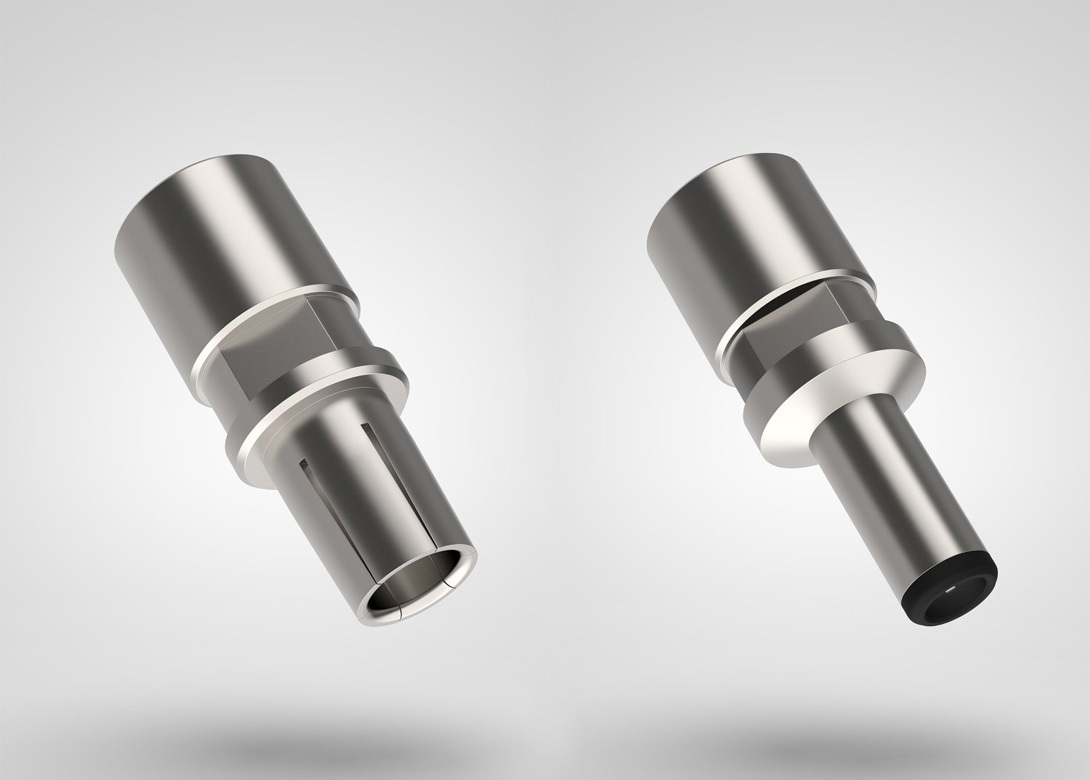

LAPP has recently announced the launch of its new EPIC® ASC axial screw contact, designed to allow for a reliable connection between the contact and the cable. With this new method of assembly, LAPP offers an effective alternative to crimping methods.

When crimping, the stripped cables or wires are usually inserted into the sleeves or plug connections and pressed together using a crimping tool. The EPIC® ASC axial screw contact, on the other hand, is a completely new design for the company. The axial screw contact, which can be rotated freely in the high-current module, simplifies assembly, prevents torsional stress and thus ensures reliable contact between the contact and the cable.

As the assembly takes place outside of the module, the fitters can see immediately whether the connection has been screwed on correctly. This prevents errors or failures that could be caused by insufficient overlap between the contact and the wire. In addition, the EPIC® ASC axial screw contact via a silver-plated contact surface. This ensures low contact resistance and minimal heat generation at the contact.

Thanks to touch protection, users have maximum protection when plugging and unplugging the high-current module. The component is also practical, as the conductor cross-sections of 35 mm2 to 75mm2 only one axial screw contact is required – an Allen key and open-end wrench are sufficient for the connection.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.