The reworkability and fluorescence despite its black colour of the new Structalit® 5751 adhesive from Panacol allows manufacturers to reduce both manufacturing costs and environmental impact by reusing electronic components mounted on PCBs.

Underfills serve the purpose of equalising stresses between chip and substrate. Chips are attached directly to the interconnection points without intermediate elements. Stresses arise at the solder bumps when the electronic modules are heated and cooled during operation due to the different coefficients of thermal expansion of the substrates. Underfill technology was developed to counteract these mechanical influences.

Structalit® 5751 is a black, heat curing, resin-based epoxy adhesive characterised by its low viscosity and linear flow behaviour. These properties enable precise application. In addition to classic contact dispensing by means of a dispenser, the uncured properties of Structalit 5751 also allow contactless dispensing for fast and precise placement of the adhesive. This underfill is has a low ion content and is ideally suited for electronic component packaging.

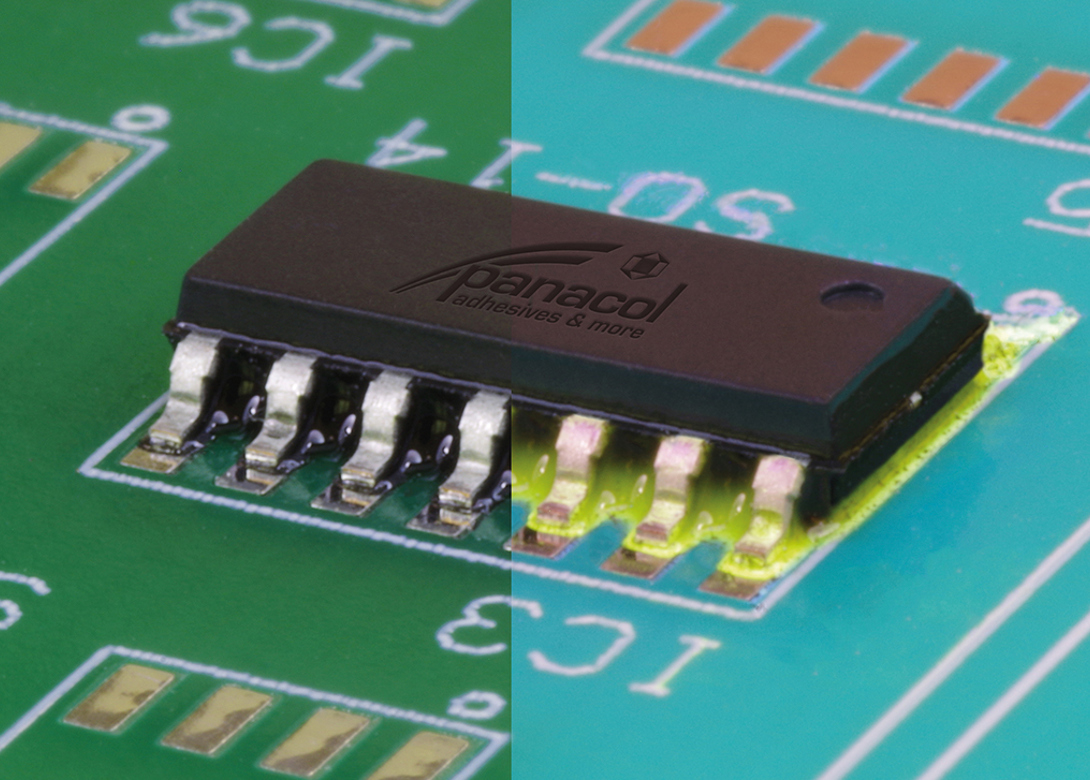

A typical feature of adhesives on PCBs is their black colouring, which is used to obscure proprietary features and for optical inspection. Optical measurement of an underfill is a common method used in the manufacturing process by manufacturers. But due to the dark chip, shallow layer thickness of the black adhesive and tight gap between the chip and the substrate, optical measurement is often difficult. Panacol has addressed this problem by incorporating an additional yellow shimmering fluorescence to the black coloration of Structalit 5751. It can be stimulated by short wavelength light of <365Nm. This makes it even easier for manufacturers to perform final inspections and speeds up production processes.

In addition to the performance and optical inspection capability of Structalit 5751, Panacol offers another important property with its newly developed underfill: reworkability. This provides the ability to re-process or repair products after assembly. For manufacturers of electronic components, this challenge is becoming increasingly important as legislation and environmental associations push for the minimisation of electronic waste. One starting point of this sustainable strategy is the reworkability and repairability of individual modules on printed circuit boards to counteract the scrapping of a complete component or module.

Structalit 5751 can also be strategically softened at specific adhesion points by applying temperatures above its glass transition temperature range of 150°C. The product becomes reworkable only when this critical temperature threshold is reached. The reworkability temperature does not reduce the protective function of the Structalit 5751 during typical PCB processing. It withstands temperatures associated with reflow soldering and additional thermal curing cycles.

The current global shortage of chips and general electronic components in the automotive and consumer electronics sectors further highlights the significance of being able to reuse components. Reuse of components is not only a benefit to the environment, it has become essential to sustain current production processes due to supply chain shortages.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.