Adhesives, coatings and curing specialist, Panacol, recently presented its new optical-grade resins and adhesives for imprint and optical-bonding application at SPIE Photonics West Expo in San Francisco, USA. The new products are suited for such uses as light carpets in the automotive industry, sensors in smart devices and wearables, creating structured light in projectors, or for time-of-flight, sensing applications.

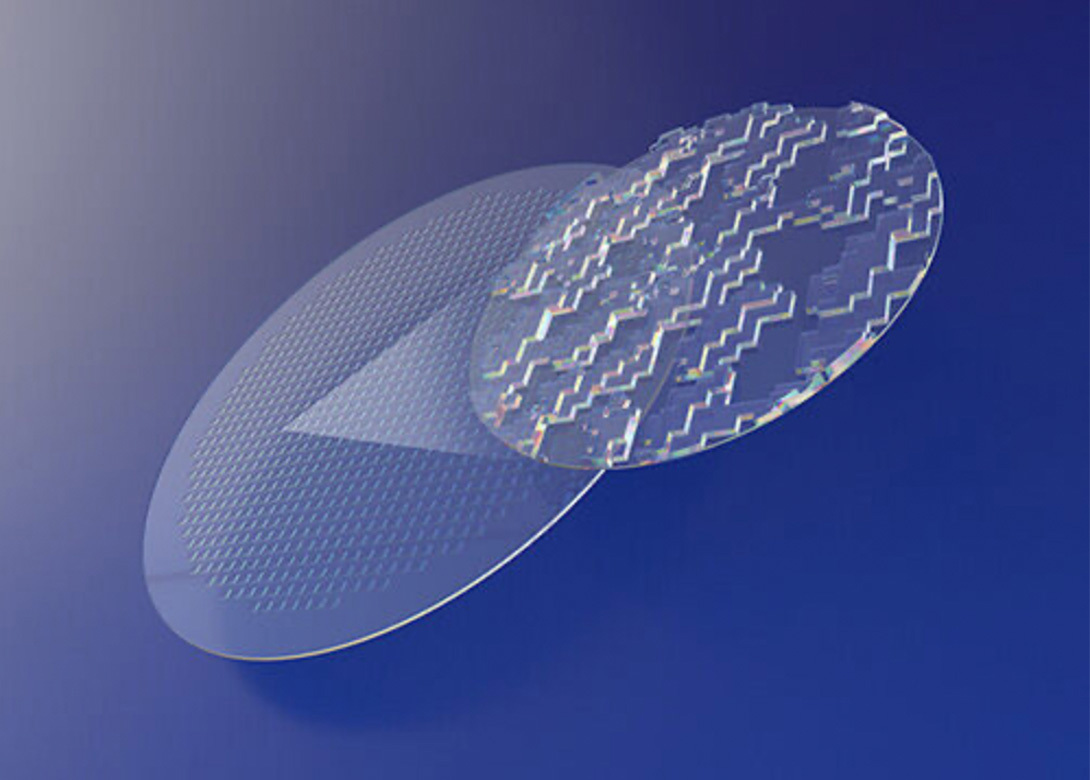

The company says its specially-formulated adhesives for imprint replication of refractive lenses and diffractive optical elements, are suitable for micro- and nano-imprint lithography, wafer-level optics, and wafer bonding. Its new Vitralit® UC 1632 and Vitralit® UC 1658 adhesives, for example, are in the viscosity range of 100 to 200 mPas and can, therefore, be easily applied via puddle dispensing, spin-coating or jetting, to offer excellent adhesion to commonly-used grades of glass wafer, as well as upcoming new polymer substrates, including optical-grade polyethylene terephthalate, or polycarbonate. Once applied and imprinted, the adhesives are quickly cured with UV light, creating a precise and durable structure on the wafer. Both adhesives are tailored specifically to meet the high demands of optical reliability, such as low yellowing, temperature stability, and shape retention. For black shading and masking purposes, Panacol will also be showing its black, UV-curable epoxy adhesive, Vitralit® BL UC 1103, which is permeable to UV light while uncured, though opaque and light blocking after curing.

Several other adhesives will be on show offering a range of properties and applications, from the UV-curable Vitralit® 7311, Vitralit® VBB-60, and Vitralit® 1860, suited to optical bonding and alignment, to its heat-curable Structalit® 5531 and Structalit® 5511, which feature high adhesion to glass and widely-used plastic substrates. Also to look out for at the expo, Vitralit® UD 8057, formulated for dual-curing using UV/visible light and atmospheric moisture, which allows the adhesive to complete its curing using moisture in shaded areas, hidden from UV/visible light.

Worth noting, these optical-grade adhesives are, according to Panacol, easily cured using Hönle intense LED curing systems, which, it states, ‘match the wavelengths of Panacol’s photoinitiators, perfectly’; once cured, the adhesives are said to be flexible and tension-equalising, thereby reducing the stress on dissimilar substrates.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.