Master Bond EP4EN-80 is a NASA low outgassing approved epoxy, which can cure at temperatures as low as 80°C, unlike conventional one component heat curing systems.

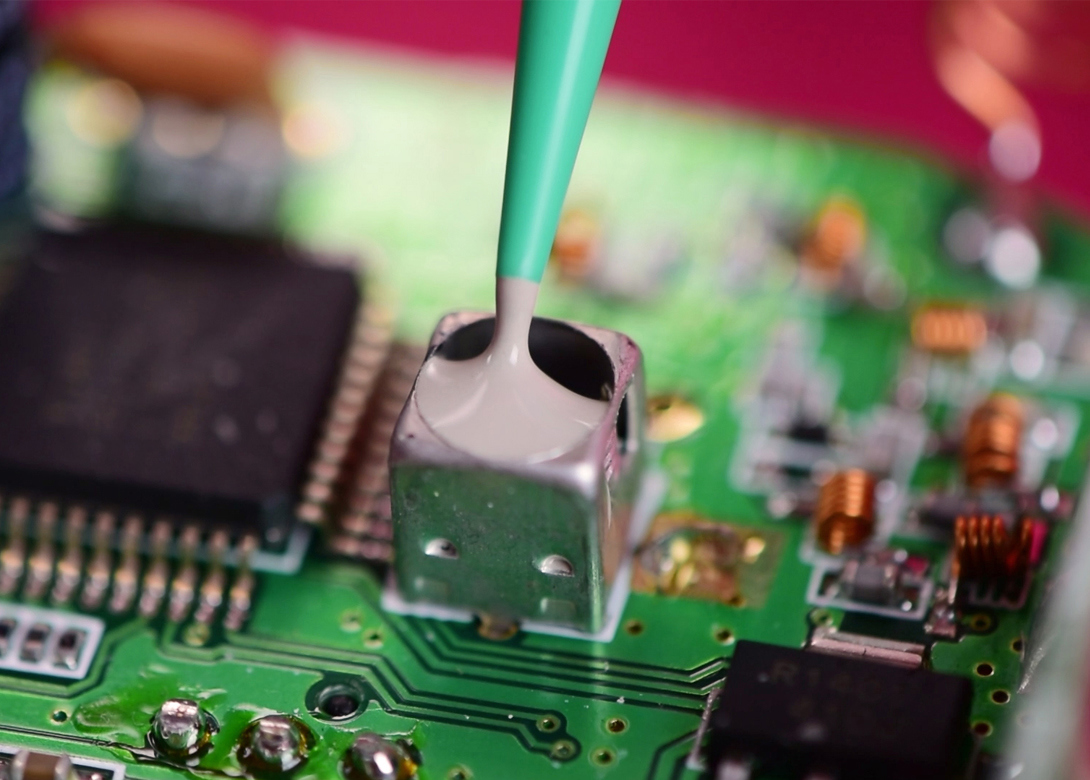

It also features a quick cure profile at 65°C for 90 minutes plus 30 minutes at 80°C - 85°C. The epoxy system requires no mixing prior to use, has a very low viscosity of 600 cps - 1,800 cps and contains no solvents. Free flowing EP4EN-80 is suitable not just for bonding, but also for small potting and encapsulations up to about a ¼ inch thick in some applications.

Due to its ultra fine particle size filler material this system offers unique gap filling and heat transfer capabilities. It has a thermal conductivity value of 0.75 - 0.85 W/(m•K) and electrical insulation with a volume resistivity of more than 1014 ohm-cm at room temperature. When used as an adhesive, EP4EN-80 can be applied in thicknesses as thin as 10 - 15 microns.

EP4EN-80 provides notable strength properties including a compressive strength of 24,000 psi -26,000 psi and an ultra high-tensile modulus of 1,200,000 psi - 1,400,000 psi at room temperature. It is serviceable over the temperature range of -50°C to +150°C.

EP4EN-80 bonds well to a variety of substrates such as metals, composites, ceramics and many plastics. It effectively resists waters, oils and fuels. This compound is gray in color and is RoHS compliant. Packaging is available in ½ pint, pint, quart and gallon sizes.

Master Bond EP4EN-80 is a one part, non-premixed and frozen epoxy system used for bonding and small encapsulation applications. This electrically insulative system features an ultra fine particle size filler material contributing to its enhanced thermal resistance properties. It can cure at temperatures as low as 80°C unlike conventional one part, heat curing systems.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.