Atotech, global supplier of speciality surface finishing solutions, has introduced its innovative super bright mid-phosphorus electroless nickel process Nichem® MP 400.

Nichem® MP 4000, a sustainable and hazard-free process, is able to plate NiP coating with very high gloss values ranging from 300 to 600 GU. This is achieved without the inclusion of hazardous cadmium and lead, which makes the electroless nickel process ELV, RoHS and WEEE compliant.

Nichem MP 400 meets the highest production quality demands and provides the flexibility needed to accommodate a wide range of surface areas and multiple substrates within one single process. It also exhibits excellent bath stability and satisfactory corrosion protection.

The process is formulated to tolerate low bath loading (0.1 dm²/l). In addition, Nichem MP 400 displays a good self initiation ability on copper and copper alloys. It also provides excellent adhesion on zincated aluminium alloys, making Nichem MP 400 a versatile process for handling a wide variety of substrates.

“Extensive field tests with customers confirm that the process provides consistent gloss and uniform appearance throughout the bath life,” said Shakeel Akhtar, global product and business development manager of Wear Resistant Coatings at Atotech.

With Nichem MP 400, Atotech has developed an environmentally friendly process, which is formulated without the use of toxic heavy metals, EDTA and boric acid. The process offers nickel-phosphorus coatings with a 7 – 9% phosphorus content, resulting in an ‘as plated’ hardness comparable to that of a plating process in the range 550-650 HV0.1.

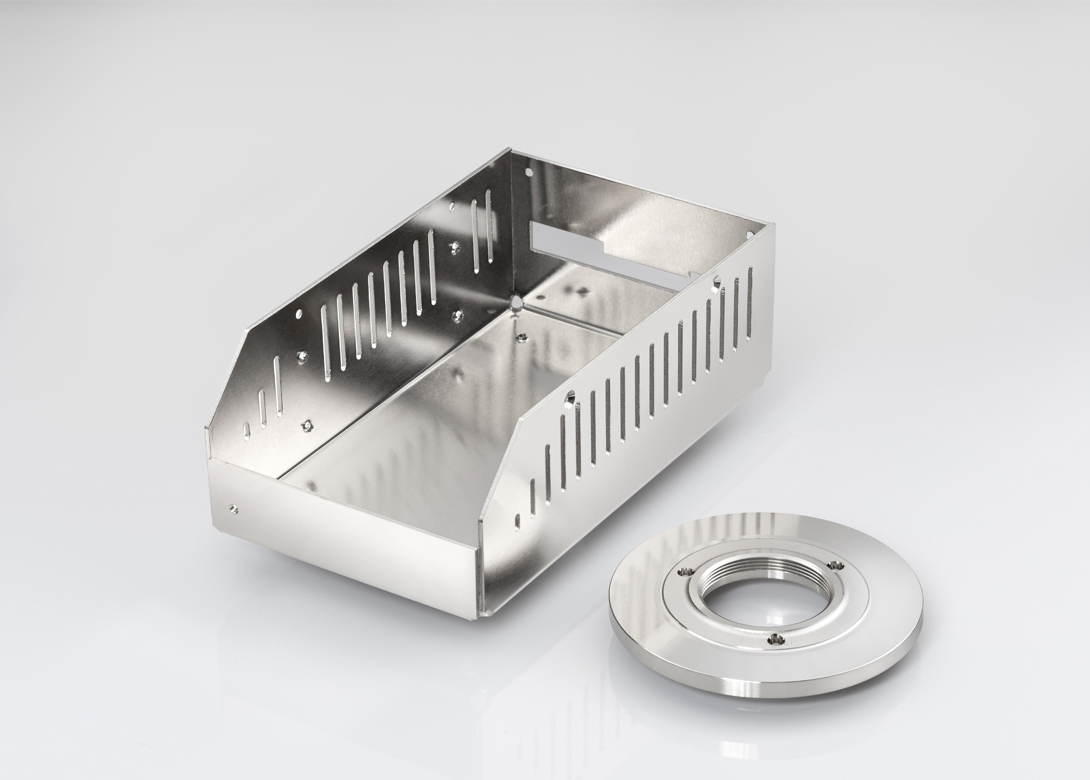

Nichem MP 400 is suitable for a wide variety of applications in consumer electronics, automotive applications, white goods, connectors and furniture that requires very bright electroless nickel deposits.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.