In tests, Techsil found its new silicone conformal coating formulations manufactured by Momentive out-perform other conformal coating materials for corrosion prevention, including acrylics, polyurethane, polyolefin and competitor silicone formulations.

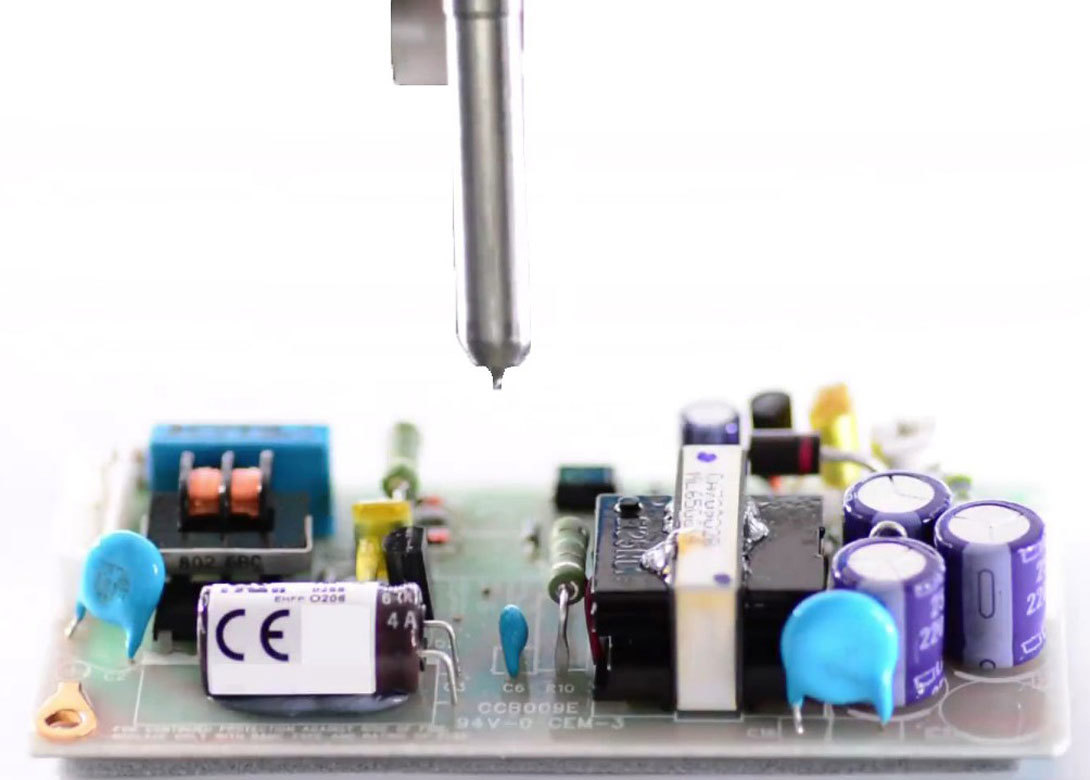

Momentive’s ECC3011 and ECC3051S silicone conformal coating materials employ a unique formulation that can help prevent the occurrence of corrosion on vital PCB components and surfaces.

These new materials dispel the commonly held perception that silicones, due to their higher gas permeability, are at a disadvantage in corrosion prevention. In tests performed by Momentive in accordance with IEC standards, the new silicone formulations performed better than other conformal coating materials in regards to corrosion prevention.

The key features of this silicone formulation are that it is a solvent free formulation making it 100% solid content with a fast tack-free time, it also contains a UV indicator for ease of inspection under black light and has a continuous operating temperature range of -40 - 150°C.

The ECC3011 and ECC3051S have been subjected to salt spray performance tests in accordance with IEC60068-2-52 Severity 5, as well as mixed gas corrosion performance tests in accordance with IEC60068-2-60 Method 4. Momentive have also tested the products in accordance with IPC-CC-830B / MIL-I-46058C.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.