Master Bond’s latest epoxy, UV23FLDC-80TK, is a moderate viscosity, cationic type system that offers both UV light and heat curing mechanisms. The new system bonds well to metals, glass, ceramics and many plastics, including but not limited to acrylics and polycarbonates.

It cures readily within 20 – 30 seconds when exposed to a UV light source emitting a wavelength of 320Nm – 365Nm. The adhesive can also undergo a secondary heat curing for shadowed areas, typically curing in 60 – 90 minutes at 80°C – 85°C. The system's adaptability to varying depths and applications, such as encapsulation and bonding, enhances its versatility.

UV23FLDC-80TK has a viscosity of 25,000 cps – 50,000 cps, and is highly thixotropic, which is advantageous for applications where minimal flow is required. It has a low tensile modulus of 250 psi – 500 psi, and a high elongation of 90% – 100% at room temperature. Its toughness and flexibility allow it to withstand rigorous thermal cycling, making it well-suited for applications where low stress is critical. The system features excellent electrical insulation with a volume resistivity exceeding 1014 ohm-cm.

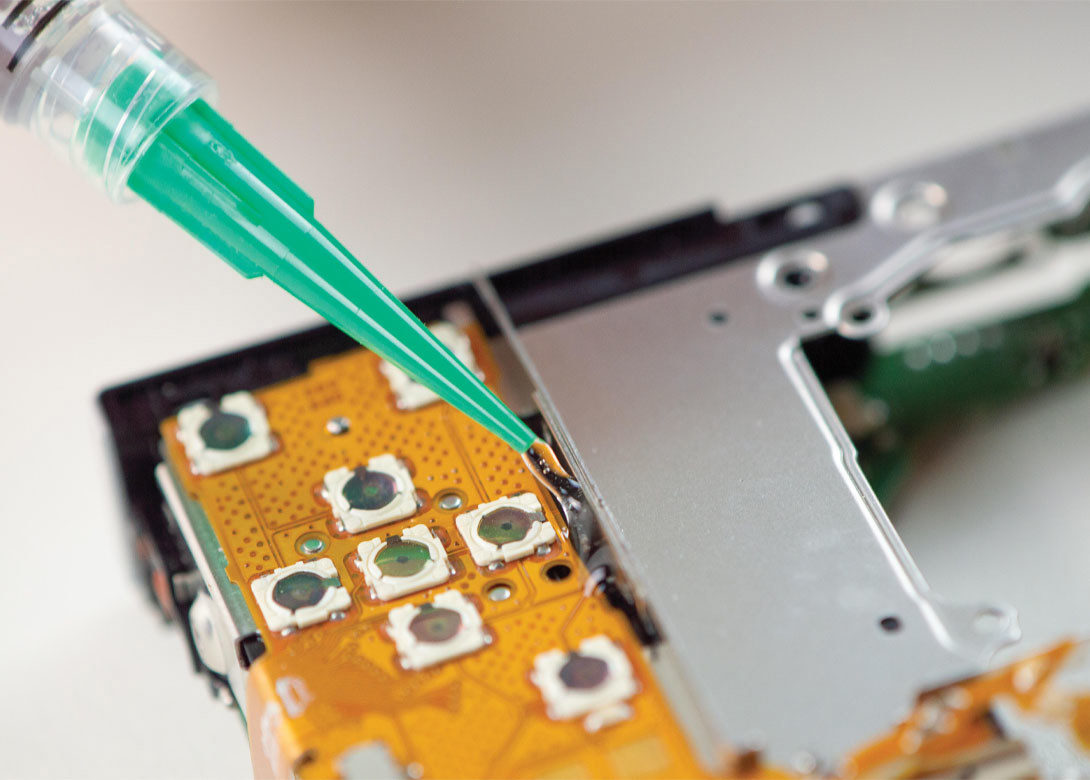

UV23FLDC-80TK is not susceptible to oxygen inhibition. It has a service temperature ranging from -80°F (-62.2°C) to +300°F (148.8°C). It is available in a wide range of packaging options, including syringes, ½ pint, pint, quart and gallon containers.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.