The latest Master Bond adhesive, EP17HTDA-2, is a one component epoxy that can be used for bonding, sealing and die attachment applications. EP17HTDA-2 is well suited for electronic and related applications, but it can also be used in vacuum situations as it passes NASA low outgassing testing.

EP17HTDA-2 has high temperature resistance and possesses a service temperature range of -80°F to +600°F (-62°C to +316°C). The dimensionally stable system features good mechanical properties with both a high modulus and die shear strength and can also withstand a variety of chemicals, including acids, bases, salts, fuels, oils, water and many solvents.

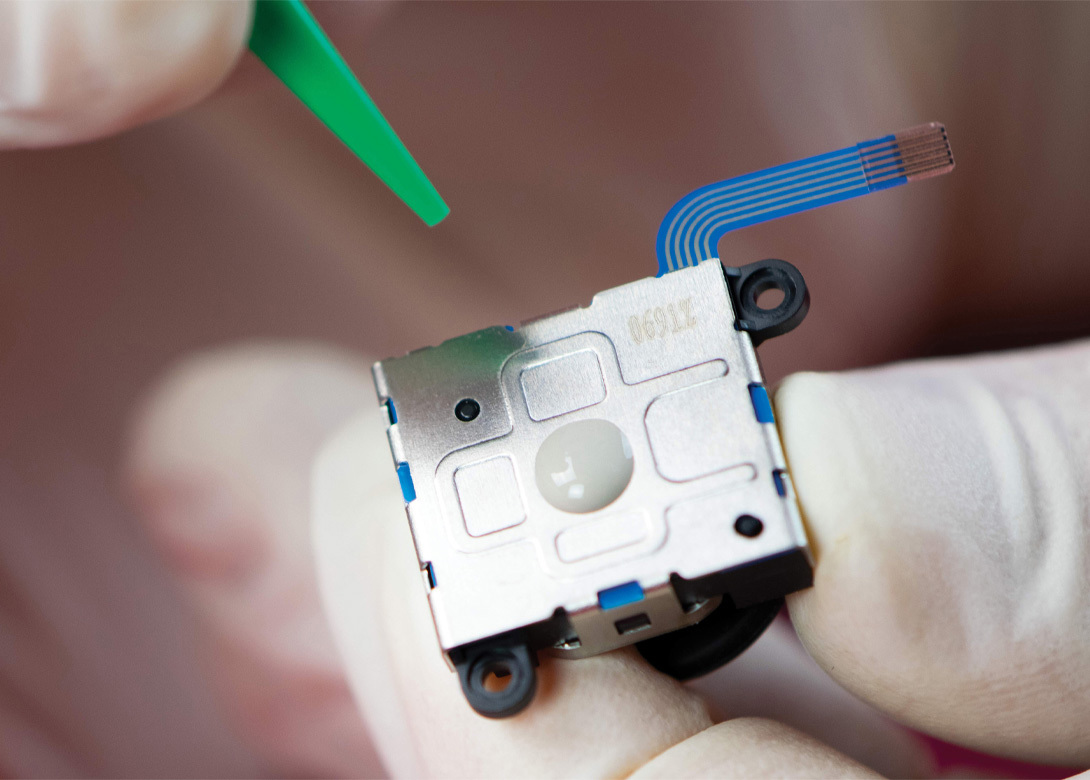

As a one part system, EP17HTDA-2 does not require any mixing and is curable in the temperature range of 300°F to 350°F (148.8°C to 176.6°C) for around 4 – 5 hours. To optimise its properties, Master Bond recommends a post cure of 2 – 3 hours at 400°F (204.4°C). It bonds well to a wide variety of substrates, such as metals, ceramics, plastics and composites. Upon curing, the adhesive delivers a tensile modulus exceeding 1,100,000 psi and a die shear strength of 20kg-f – 23kg-f at room temperature. EP17HTDA-2 also has minimal shrinkage upon curing.

EP17HTDA-2 is a thixotropic paste, available in 10cc and 30cc syringes for automated dispensing, and has a shelf life of 3 – 6 months when stored at 40°F – 50°F (4.4°C – 10°C).

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.