DELO has presented light fixation for two component epoxy resins. Thanks to this hybrid chemistry, users benefit from faster, less complex production processes and simplified logistics.

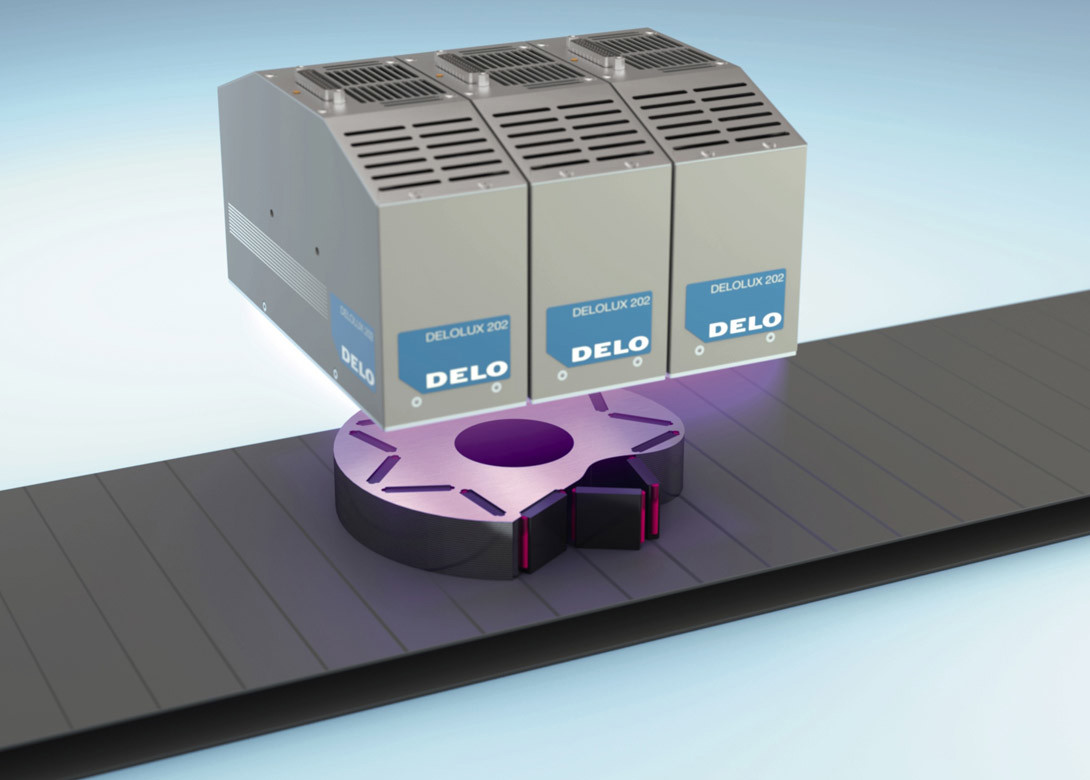

DELO-DUOPOX DB8989 provides unprecedented speed for a two-component epoxy resin. It secures the components against slipping in just a couple of seconds, so that processing of the entire assembly can go ahead immediately. After an irradiation time of only 5 seconds at an intensity of 1000 mW/cm², fixing strength of 1 N/mm² is achieved.

Reliable final curing including shadowed areas is the same as for regular two-component products at room temperature or speeded up, typically at 80°C for 60 minutes. The first option is likely more attractive to most users since it saves them investment and energy costs for heat curing, not to mention space on the production floor, and cycle and throughput rates are radically reduced. Since dispensing, joining, and light fixation take less than a minute, the next production step can begin much faster than the usual 15 to 90 minutes.

In addition, the new technology markedly simplifies logistics for users as products need not be transported and stored in a cooled state. A storage life of 12 months enhances production flexibility and enables the use of larger, and thus more cost-effective, containers.

“This new development is nothing short of a revolution. It combines the benefits of light curing with the strengths of two-component products. In the future, all users will need is a mixing system and lamps. Ovens, energy, and space on the shop floor can be saved, not to mention a huge amount of time,” says Karl Bitzer, head of product management at DELO.

DELO-DUOPOX DB8989 provides good strength even when exposed to high temperatures and humidity. The adhesive thus achieves a tensile shear strength of 28 MPa on aluminium, and even during the ageing simulations required in the automotive industry, this value is maintained, for instance, after 500 hours' storage at 85°C and 85% relative air humidity or at 150°C. As such, it can be used for structural bonding of, for example, rare earth magnets in electric motors. Thanks to low outgassing and shrinkage, the product is even suitable for opto-electronic applications in cameras.

Two component adhesives are well-known for good strength, reliable curing at room temperature, good media resistance, and easy logistics. In the case of many high volume applications, the time lapse before reaching initial strength was deemed a major disadvantage – until now. In the future, DELO plans to develop several other two component products with light fixation, including encapsulants for the sensor industry.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.