This year at Southern Manufacturing Exhibition, engineers and buyers seeking expertise in spring technology will be able to talk directly with the technical experts at Lee Spring on stand D245 from 11th – 13th February at Farnborough.

Lee Spring has recently expanded its UK manufacturing operations with the acquisition of Longcroft Engineering located in Lancashire between Manchester and Leeds. This acquisition provides Lee Spring with additional resources and capabilities to engineer and manufacturer a wider range of products in the UK.

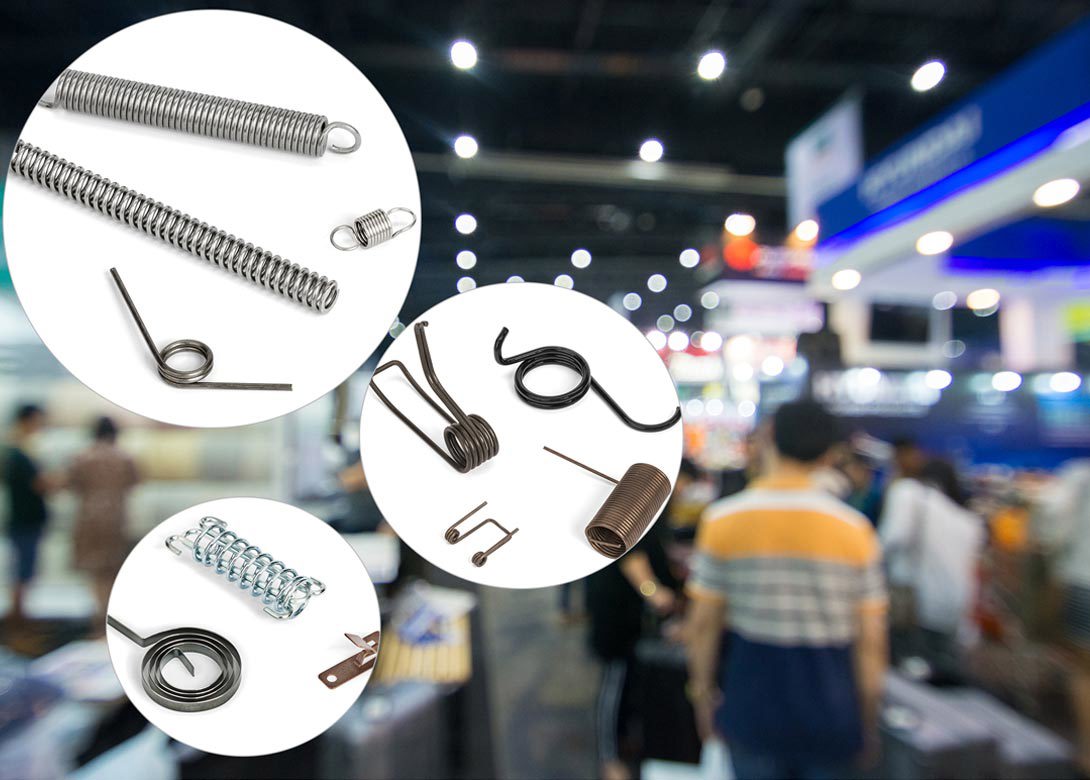

Lee Spring offers a broad range of both ex-stock and custom-made compression, extension, torsion and wave springs, plus custom made wire form and flat spring manufacturing expertise. The expansion of additional manufacturing capability within the UK also strengthens and expands the support and capabilities for short run and prototyping of complex springs.

Lee Spring have a history of combining design expertise, technical excellence, specialist machinery and manufacturing knowhow to design, develop and manufacture springs and pressings to customer requirements. They can solve many customer problems by adjusting a current spring design or by a complete redesign. They can also ‘reverse engineer’ springs even from damaged and broken parts for oil and gas, valves, rail, medical, marine, lighting, electronics and telecommunications, general engineering, and precision engineering sectors.

Often manufacturing from exotic materials, Lee Spring can provide stockholding and a call off facility against JIT (Just In Time) orders. This gives customers the advantage of the stock they want, when they need it and with the price advantage because of raw materials and production savings based on annual volumes. Certification is to ISO 9001:2015, as well as to the specific quality standard requirements of both UK and international customers across a wide range of sectors.

The Lee Spring standard ex-stock catalogue now exceeds 25,000 parts, including numerous speciality springs. Materials include steel, stainless steel, cobalt/nickel alloy, bronze, brass, music wire and composite plastics. In addition, Lee Spring offers extensive custom design and manufacture services for long and medium range production runs and one-off/prototypes.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.