Dymax expands its range of encapsulant materials with the introduction of Multi-Cure 9037-F for a variety of glob-top, chip-on-board, chip-on-flex, chip-on-glass, and wire-tacking/bonding applications.

The product cures in seconds upon exposure to UV/visible light and has a secondary heat cure for shadow areas caused by high-profile components on printed circuit boards.The material features improved flexibility and resiliency for a variety of glob-top, chip-on-board, chip-on-flex, chip-on-glass, and wire-tacking/bonding applications.

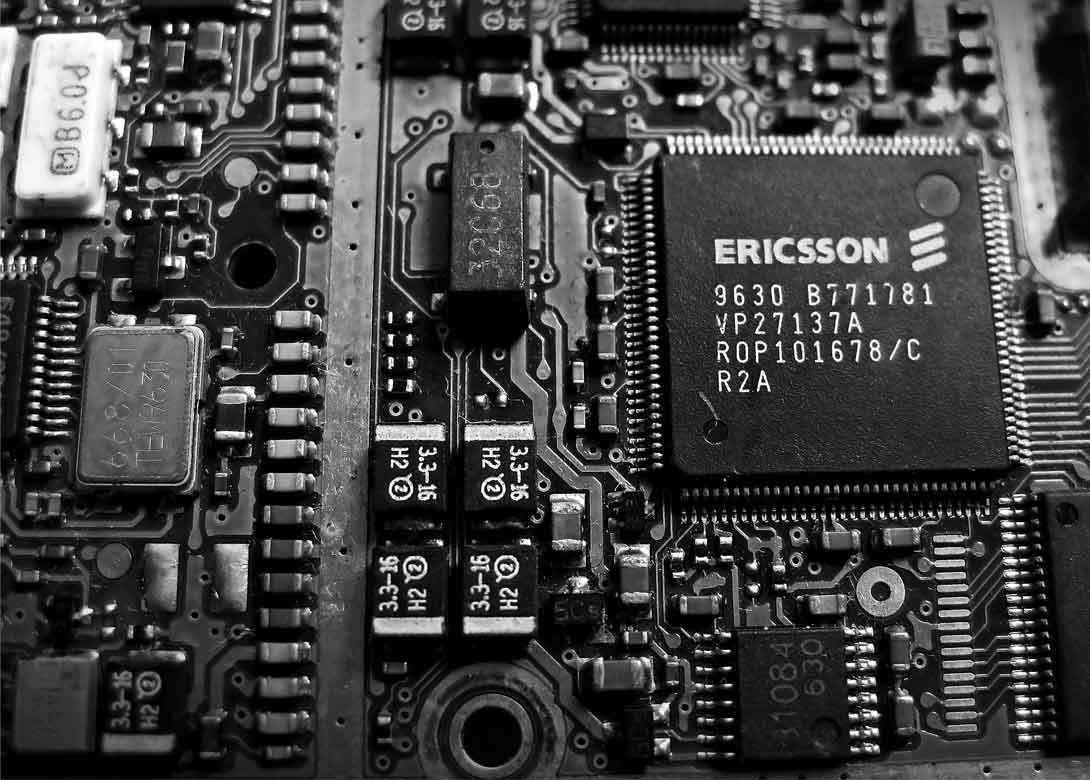

It is well suited for encapsulation of critical components on flexible and rigid circuit board materials such as FR-4, Kapton®, and glass, and contains no sharp, abrasive, mineral, or glass fillers to abrade fine wires.

Multi-Cure 9037-F has excellent moisture and thermal resistance, making it a good candidate for use as a corrosion guard for wire-bond connections in battery management systems. Additional uses include encapsulation of components on circuit boards found in automotive ADAS and infotainment systems, aerospace and defence applications, and consumer electronics. Formulated with blue fluorescing technology, the material is highly visible on encapsulated PCB modules when exposed to low-intensity black light for easy visual quality inspection.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.