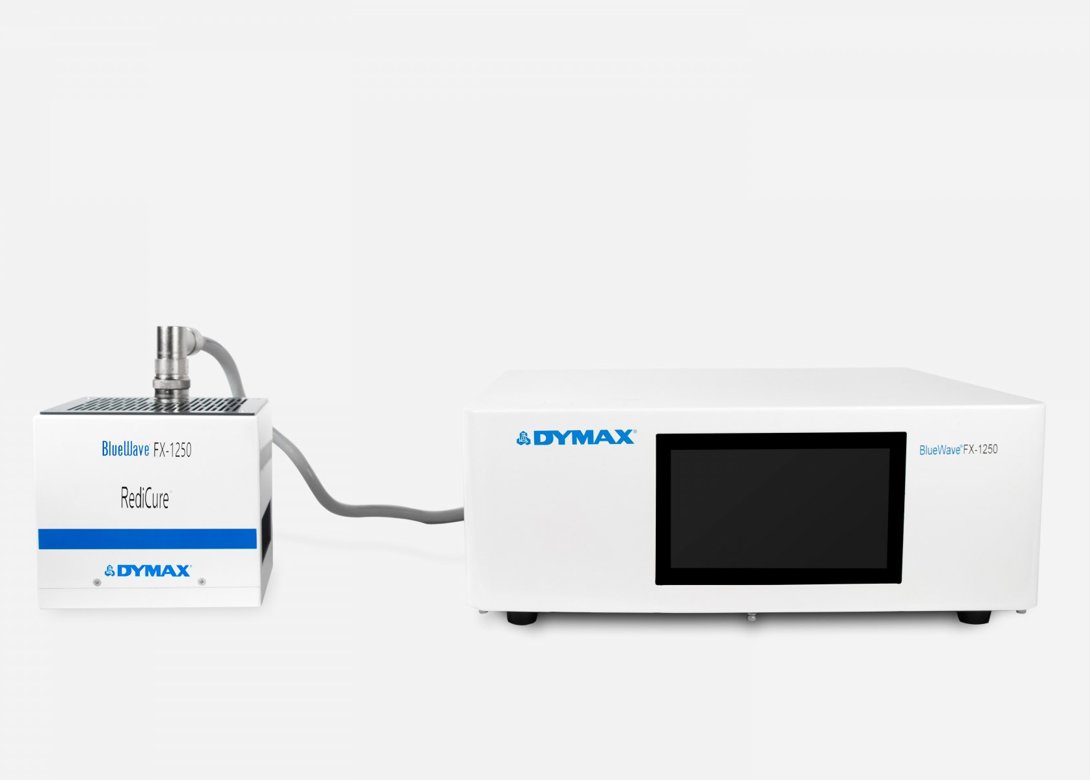

The BlueWave® FX-1250 is a high intensity flood LED curing system that delivers true, high irradiance LED light for the best speed, depth and fullness of cure from any Dymax LED.

For the user who needs flood curing systems for large areas, the FX-1250 combines intensities over 2W/cm2, with a 5 inch x 5 inch (127mm x 127mm) curing area and high uniformity to provide a superior cure.

The FX 1250 light curing equipment includes an easy to use control platform, featuring a 7 inch touchscreen with an intuitive interface. It can be activated, controlled and remotely monitored by PLC, and also store programs and parameters for repeatable processes. The new controller enhances and diagnostics by continuously monitoring the health of the emitters and controller and reporting faults directly to the controller screen. A single controller can operate up to two emitters to save on cost and space in the installation. Use extra emitters to increase the area or light delivery or use multiple wavelengths to extend application flexibility.

Additionally, the FX-1250 led curing technology provides a quiet, efficient operation while also minimising heat emission. The system is coupled with a full suite of accessories including a stand and full light shield for maximum flexibility. It is also compatible with the UVCS 3.0 conveyor system, which can mount up to four FX-1250 emitters for fast, full cures in a high-speed process.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.