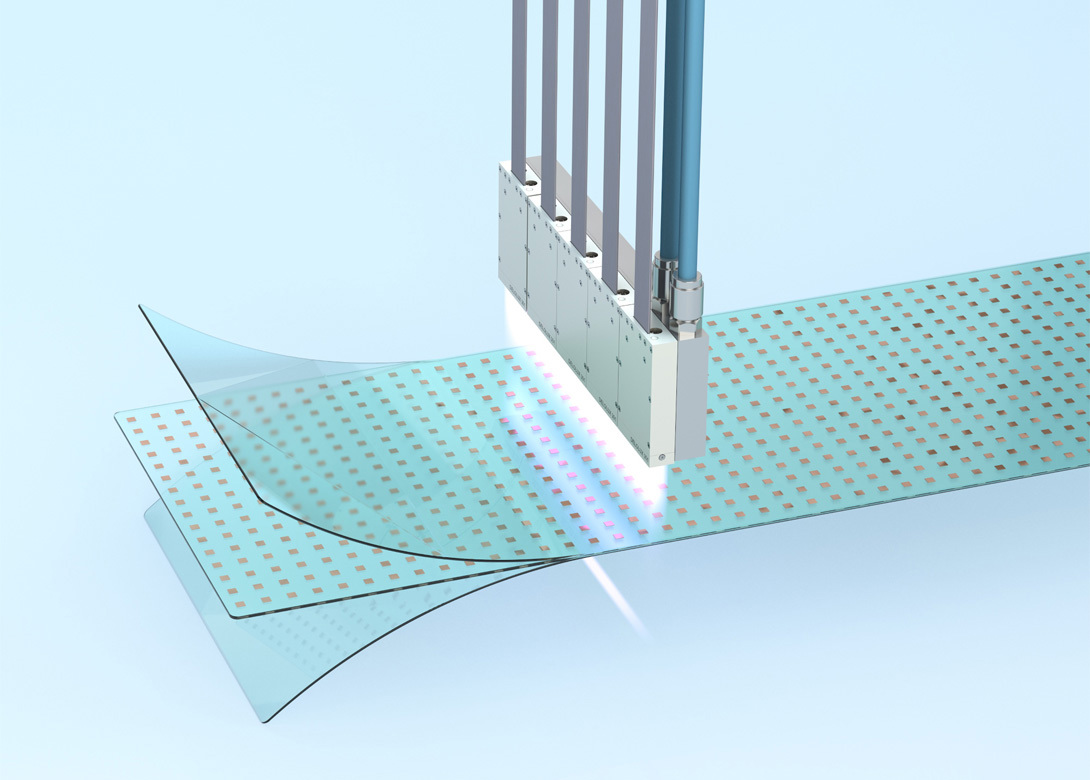

DELO has recently developed a line lamp for curing adhesives and other multi-functional polymers, DELOLUX 301. This lamp is suitable for highly automated processes in small and narrow production lines, like those commonly found in consumer electronics assembly. It can also be used, for example, in the lamination of thin-film solar cells.

Thanks to its high intensity of up to 30 W/cm², the DELOLUX 301 enables maximum speeds for curing adhesives and other multi-functional polymers, but also allows for large working distances of up to 100mm from lamp to components. Also, the lamp’s compact lamp head dimensions allow for a high degree of flexibility for integration into production systems.

DELOLUX 301 can be operated as a single head or be seamlessly combined to form a larger array. When the lamp heads are combined in up to three directions, users can easily implement individual as well as homogeneous exposure geometries.

In its standard variant, DELOLUX 301 is available with water cooling with optimised water flow, suitable for clean rooms. The lamp is available with wavelengths of 365Nm, 400Nm and 460Nm, making it suitable for UV-curing as well as light-curing products. DELOLUX 301 also has a service life of more than 20,000 hours.

The plug and play lamp head is controlled and supplied with power via the base units of the DELOLUX pilot A series, which are available as touch and PLC-capable models. Both models feature automatic temperature compensation so that the LEDs deliver constant intensity even as they heat up.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.