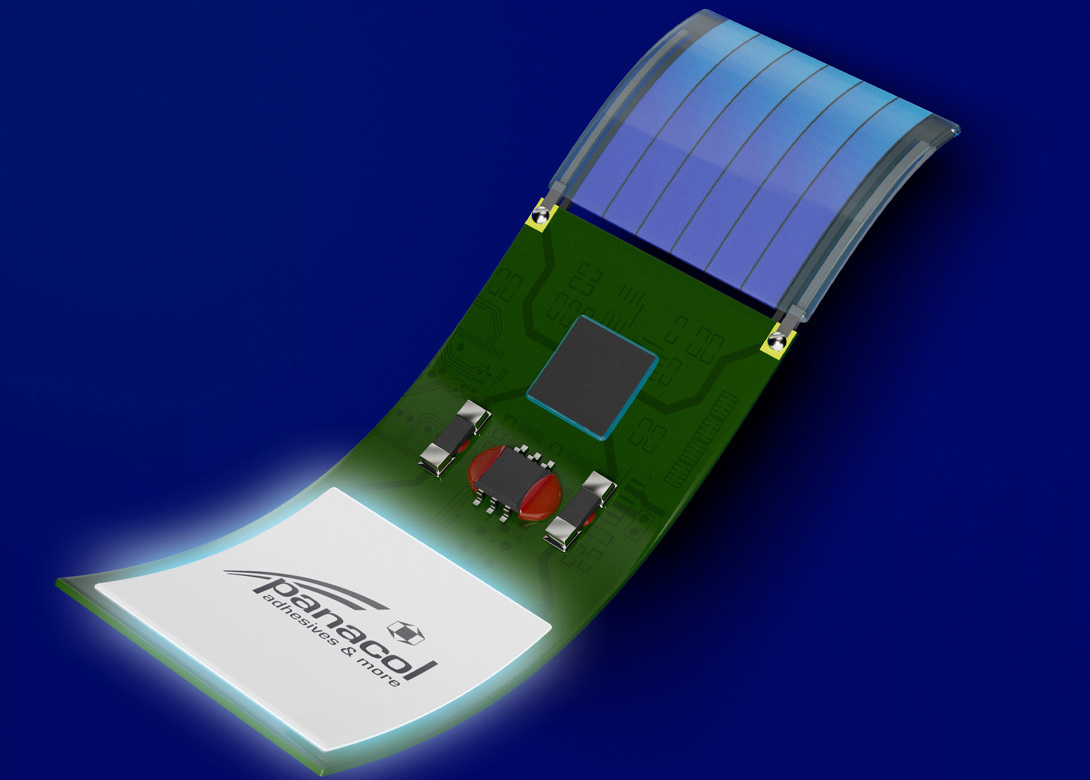

As flexible electronics manufacturers push traditional boundaries, such as functionality and design flexibility in consumer electronics, Panacol and Hönle UV Technology have successfully developed turnkey solutions, comprising multi-functional adhesives and UV curing equipment, that can be tailored for novel photovoltaic and flexible electronic applications.

The new UV and UV-LED curable adhesives for Organic Photovoltaic (OPV) applications were developed for laminating barrier foils. They provide higher resistance to environmental stresses, have an improved compatibility with PV material, as well as exhibit a low water vapour transmission rate.

Being UV-curable, these adhesives offer high throughput processes, including roll-to-roll, that can be run with greater efficiency, thereby reducing total cost of ownership. The adhesives characteristics, such as flow properties, can be modified in this context to suit the application process, perfectly according to Panacol.

Flexible and bendable UV adhesives have also been created for more traditional applications that are now being performed on flex circuits, including new underfills for die attach/die bonding, as well as structural adhesives being used for component edge bonding.

All UV adhesives from Panacol can be cured with high intensity UV and/or UV-LED curing systems from Hönle, which match the wavelengths of the Panacol photoinitiators exactly. Their light footprint options range from 3mm diameter spot units to linear LED arrays that can exceed one metre in length, making it the perfect choice for smaller and larger irradiation areas.

As for some of the latest conductive adhesives from Panacol, these are being used to secure flexible resistors and create flexible electrical connections in solar cells, touch sensors and wearable devices. They include a one component, silver filled conductive adhesive that adheres effectively to plastics, including polyimide, PC, PVC, ABS, and FR4 boards. When fully cured, the adhesive is very flexible with high peel strength, making it suitable for use in applications subject to vibration, oscillation or rapid temperature changes. One of its major advantages is its ease of handling and storage, where only refrigeration is required.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.