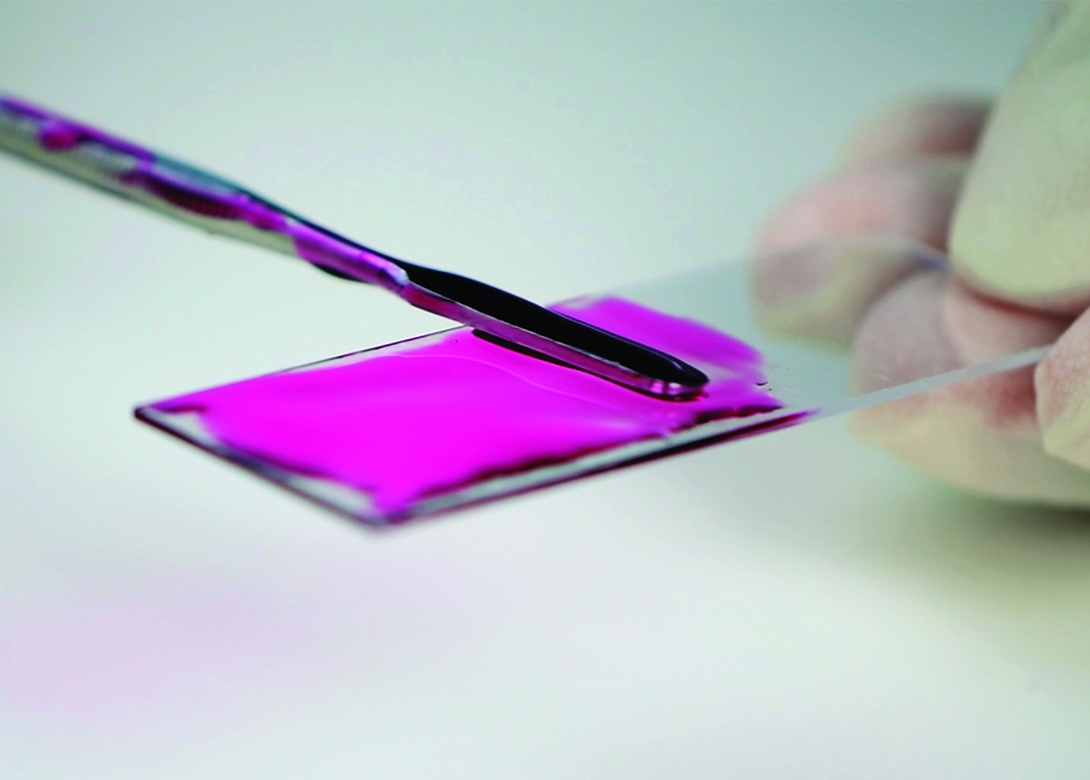

The latest Master Bond adhesive, UV15RCL, is a low viscosity, cationic type UV curing system suitable for various bonding and sealing applications. Thanks to its special colour changing feature, users have a visual indicator for when the UV light has reached the polymer.

The originally red material changes to clear once exposed to UV light, although Master Bond highlights that this change in colour from does not indicate a full cure. By giving immediate visual feedback, UV15RCL offers processing and handling advantages over conventional systems. For bonding and sealing applications, the product adheres well to metals, glass, ceramics and many plastics, including acrylics and polycarbonates.

Curing under UV light typically takes 30 – 60 seconds with a broad-spectrum UV lamp emitting light with a wavelength range between 320Nm – 365Nm. The minimum energy required for this curing process is 20 – 40 milliwatts per cm2.

The adhesive features a high glass transition temperature (Tg) of 90°C – 95°C, however, when post cured for 1 – 2 hours at 125°C, the Tg can increase to 125°C – 130°C. UV15RCL has a service temperature range from -80°F (-62.2°C) to 350°F (176.7°C). This non-solvent based system cures tack free and also has a low viscosity of 115 cps – 350 cps, making this material ideal for spin coating. Additionally, the adhesive is an excellent electrical insulator, with a volume resistivity exceeding 1014 ohm-cm.

UV15RCL is available in a wide range of packaging options, including syringes, ½ pint, pint, quart and gallon containers.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.