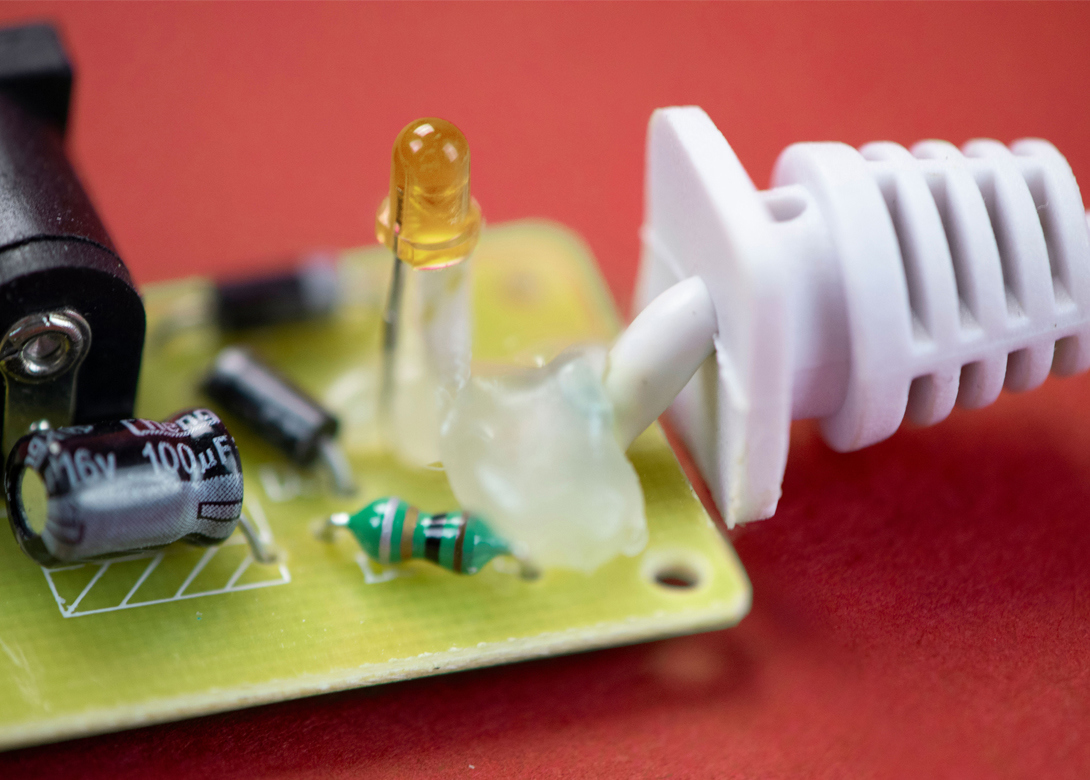

Master Bond EP21NS is a two part epoxy that may be used for bonding, coating, sealing and potting/encapsulating. It has a nanosilica filler that imparts dimensional stability and abrasion resistance.

When measured according to ASTM D4060, standard test method for abrasion resistance, with CS-17 wheel for 1,000 cycles, EP21NS exhibits a very low weight loss of 25mg. This formulation is a reliable electrical insulation with a volume resistivity greater than 1015 ohm-cm, an outstanding dielectric constant of 2.6 at 16.4 GHz and a dielectric strength of 450 volts/mil at 75°F, for a 1/8th inch thick specimen. It is serviceable over the temperature range of -80°F to +250°F.

This system has a long working life and good flow properties with a moderate mixed viscosity of 50,000 cps - 90,000 cps. The mix ratio of EP21NS is 1 to 1 by weight, and its optimal cure schedule is overnight at room temperature followed by 4 to 5 hours at 150°F. It features very low shrinkage upon curing, a low coefficient of thermal expansion of 30 - 35 x 10-6 x in/in/°C and a compressive strength of 16,000 psi - 18,000 psi.

This compound bonds well to a variety of substrates including metals, composites, glass, ceramics, rubbers and many plastics. EP21NS is resistant to water and salts. It is packaged in ounce kits, ½ pint kits, pint kits, and quart kits. The colour of Part A is translucent and Part B is amber. EP21NS does not contain solvents and is RoHS compliant.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.