Dow Inc has launched its DOWSIL™ TC-3065 thermal gel, a one part thermally conductive gel developed to dissipate high amounts of heat away from sensitive electronic components.

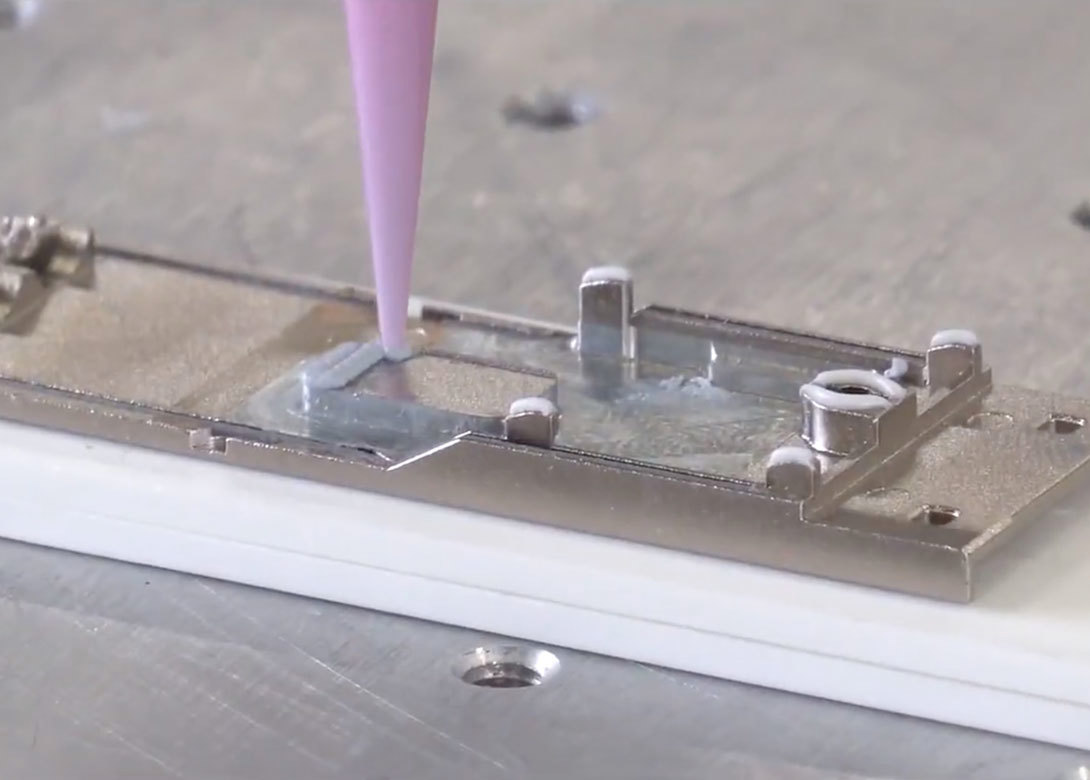

DOWSIL™ TC-3065 easily fills gaps due to its excellent wetting ability, and can replace fabricated elastomeric thermal pads that may fail to protect electronics from the high heat associated with 5G’s greater power densities. After full curing, Dow’s new thermal gel eliminates silicone oil bleeding and has ultra low levels of volatile organic compounds. To achieve high-levels of manufacturing efficiency, the gel supports automatic dispensing and heat curing after assembly.

Dow says this thermal gel is a soft, stress relieving, and shock damping silicone gel with a thermal conductivity of 6.5W/mk. It also has an extrusion rate of 60g/m and supports auto dispensing. DOWSIL TC-3065 resists slumping during vertical assembly and completely fills uneven spacing. This dispensable material accommodates higher part-to-part tolerances that can challenge fabricated thermal pads with its constrained dimensions. It is supplied as a non-flowable gel and supports a bond line thickness as thin as 150 microns when high pressure is applied.

“Thermal interface materials for 5G technologies need to quickly dissipate high amounts of heat, and electronics manufacturers also need advanced material solutions that support sustainability and efficient assembly,” said Samuel Liu, marketing manager and communication segment leader at Dow. “DOWSIL TC-3065 thermal gel provides an attractive balance of properties that checks all the boxes. This strong new addition to Dow’s growing portfolio of thermally conductive silicones can help drive the development of next generation applications in a way that is both efficient and environmentally responsible.”

DOWSIL TC-3065 can be dispensed onto substrates such as aluminium heat sinks and encapsulated chips that have an epoxy surface. After assembly it can achieve complete curing by applying 100°C for 30 minutes or from the heat generated by the component. If rework is required, the gel can be removed completely without leaving behind a residue after curing. At room temperature the working time or open time is generally five days, which helps reduce scrap rates during electronic assembly.

Dow explains that unlike some thermally conductive elastomeric pads, the new gel will not bleed silicone oil after full curing, which helps to avoid contamination of device surfaces that can degrade performance. It is resistant to humidity and other harsh environments, and will not crack during long-term aging.

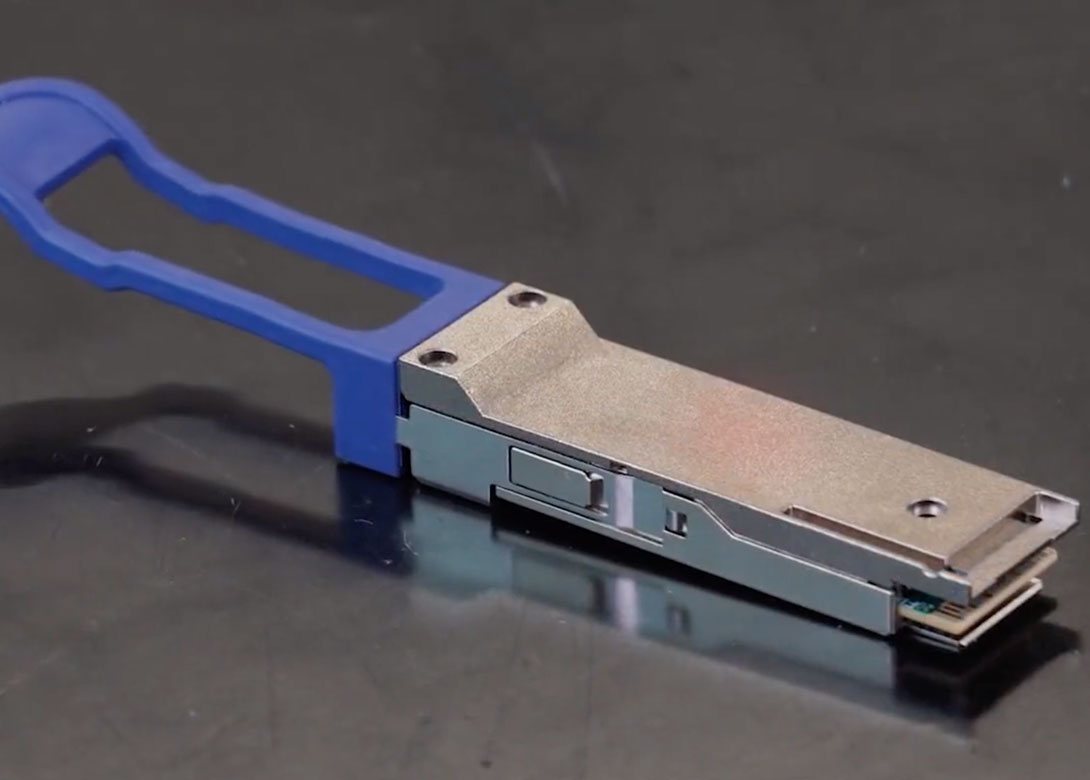

DOWSIL TC-3065 thermal gel can be used for optical transceivers, ethernet switches and routers, high-speed solid state disks and other network devices.