Cutting-edge adhesive combines exceptional mechanical and conductive properties with strong EMI shielding for today’s most demanding applications in the transportation, communications and consumer markets.

Dow has introduced its new DOWSIL™ EC-6601 Electrically Conductive Adhesive, a next-generation material engineered for reliable performance and electromagnetic compatibility (EMC) in demanding electrical and electronics applications in the transportation, communications and consumer markets. This novel adhesive combines strong electromagnetic interference (EMI) shielding capabilities across a wide range of frequencies with durable mechanical and conductive properties over time, underscoring how Dow is further growing its highly differentiated EMI shielding solutions portfolio.

“Today’s most innovative electrical and electronics technologies need a strong adhesive with stable EMI shielding across a broad frequency range, including the millimeter range for 5G. Our new DOWSIL™ EC-6601 Electrically Conductive Adhesive provides this, along with long-lasting mechanical and electrical performance, and the ability to bond to a variety of substrates. With our innovative customer-centric approach, formulation expertise, and supply chain integration, Dow is a proven collaboration partner with the growing portfolio of solutions needed to address today’s toughest EMI challenges,” comments Jeroen Bello, global senior marketing manager for new technologies at Dow.

DOWSIL™ EC-6601 Electrically Conductive Adhesive is uniquely formulated to form strong bonds to many substrates and has greater than 150 percent elongation to enable flexibility at the joints. With its longer shelf life, better material strength, increased flexibility, stronger adhesion, and greater electrical conductivity, this innovative new adhesive provides key advantages over other conductive elastomers, a category of materials that is used widely in today’s printed circuit board and advanced systems assembly market.

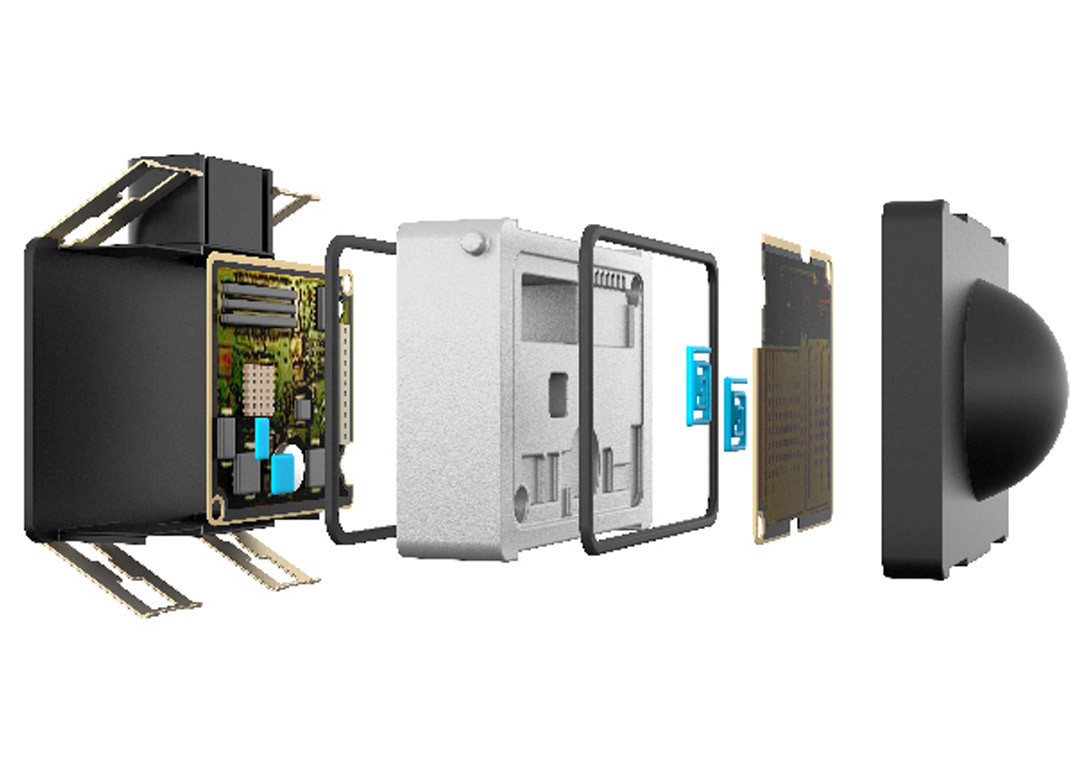

In the transportation industry, for example, the electrification of vehicles is driving increased demand for greater connectivity, reliability and compliance with tight safety regulations that require high-performance EMI shielding. Applications such as electronic control units (ECU), cameras, radar, LiDAR, sensors and batteries all need dependable performance over time with zero defects. The new vehicle architectures for autonomous vehicles are also raising the bar for EMI shielding because of their many sensor configurations.

In the communications space, 5G base stations and optical interconnects that need greater data transfers at faster speeds are challenging EMC experts. Consumer electronics with high-density packaging and smart architectures are also susceptible to electronic pollution that can disrupt or disable circuits.

DOWSIL™ EC-6601 Electrically Conductive Adhesive provides the stable EMI shielding that is required for these and other applications while maintaining its properties and electrical conductive.

DOWSIL™ EC-6601 Electrically Conductive Adhesive can be used as an adhesive, formed-in-place gaskets (FIPG), or cure-in-place gaskets (CIPG). This silicone elastomer has an optimized dispense rate and withstands high temperatures, humidity, vibration, compression and tensile stress. With its high elongation, the material can stretch to support the movement of a joint when used as an adhesive, FIPG or CIPG. DOWSIL™ EC-6601 Electrically Conductive Adhesive contains premium fillers, provides excellent corrosion resistance and is the latest innovation from an industry leader with more than 15 years of experience in electrically-conductive silicones for advanced assembly.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.