Thermal Management is the hottest topic in electronics at the moment - effective control of heat is an increasing concern among today's electronic device manufacturers and, as products become more compact and powerful, the need to dissipate damaging heat effectively is greater than ever.

Chris Dilley, director from UK based adhesive specialist, Techsil Ltd, is taken aback at the pace of change. “Ten Years ago everybody wanted to seal this and IP rate that, today more than half our enquiries are for thermal management applications, which is good news for us as we’ve got over 20 different TIM (Thermal Interface Material) solutions now”.

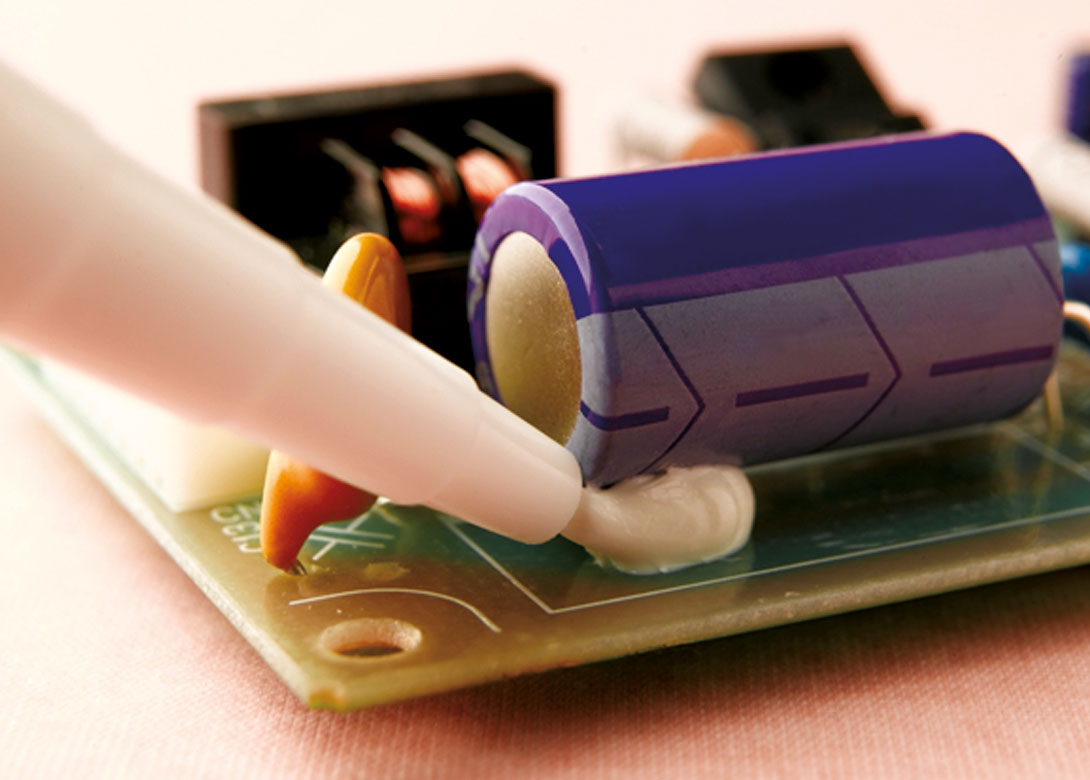

As electronics get smaller and hotter during brief moments of high service stress, what it is necessary to find a solution to the build-up of heat. Too much heat can reduce service life and affect reliability. Air is a poor conductor so manufacturers have developed innovative thermally conductive silicone adhesives that can be robot dispensed to help quickly conduct heat away from the PCB to the heat sink (usually an aluminium case lid) or used as potting to act as a temporary heat store to allow heat to dissipate over time. Any air filled gaps, even microscopic, will inhibit the efficient transfer of heat.

Chris comments, “Thermal pads are one solution that have been around for a while but we find that our customers prefer the flexibility of a paste, as no two surfaces are completely smooth and therefore often do not mate perfectly leaving air gaps. The paste is more forgiving and fills the gaps, eliminating the air on the surface very well. Also it can be robot dispensed in intricate patterns. One customer we have worked with recently uses 6 spots of thermal paste on the reverse of the PCB positioned underneath the bigger components that get the hottest. The robot dispenses this consistently and accurately in just a few seconds on a high volume line.”

Silicones are very versatile and have the advantage of being able to bond to difficult combinations of materials, plus they provide reliability over a wide temperature range and in difficult environments. Used for potting, their flexibility when cured provides excellent protection to sensitive electronics by absorbing mechanical vibration and thermal shock. Alternatively silicone greases can be used as gap fillers if there is a need to re-work the component at a future date.

Before choosing a thermally conductive adhesive it is important to consider a number of factors and not just select the one with the highest thermal conductivity. For example:

• What substrates are you bonding together? What is the size, dimensions and joint design?

• How strong does the bond need to be?

• How quickly do you need the adhesive to cure?

• How will it fit into your production line? What cure mechanism is acceptable in your process?

• For potting applications – what is the volume of the area to be potted? If large, a slower curing product could be better. How complex is the part? Will the adhesive flow easily around the part leaving no gaps?

“Application technology is really important because less is always more. The thicker the layer of thermal interface material, the more likely that this will actually limit the rate at which the heat is dissipated. This is because the heat sink itself will have a higher thermal conductivity than the paste, so the aim is to get heat to the heat sink as quickly as possible and this is achieved through thin BLT’s (Bond Line Thickness).

“Every application and every surface are different and that is why we like to get involved at the design stage to understand the substrates being used, the heat generated, how to eliminate the air and achieve a good BLT for the client. Ultimately this means we can achieve a very efficient heat transfer and good thermal management solution.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.