Semiconductors are used in all sorts of electronic devices and as such, global sales continue to grow. However, manufacturing semiconductors is a highly challenging and competitive market. Maintaining a responsive, efficient and reliable supply chain is a key aspect that can help semiconductor manufacturers to succeed. Optimas Solutions, a global industrial distributor and service provider, looks at the challenges for semiconductor manufacturers and how suppliers can address them, providing an effective service.

To operate electronic devices, it is necessary to control the electricity, e.g. to turn on/off the device. To do so, it is essential to use material that can dynamically change its resistance. Semiconductors are materials whose electrical properties can be modified. They can have either full or no conductivity, depending on the conditions they are exposed to. For example, the application of currents or voltages, irradiation by infrared (IR), visible light, ultraviolet (UV) or X-rays provide enough energy for the electrons in the atoms to change their band energy and generate an electric current.

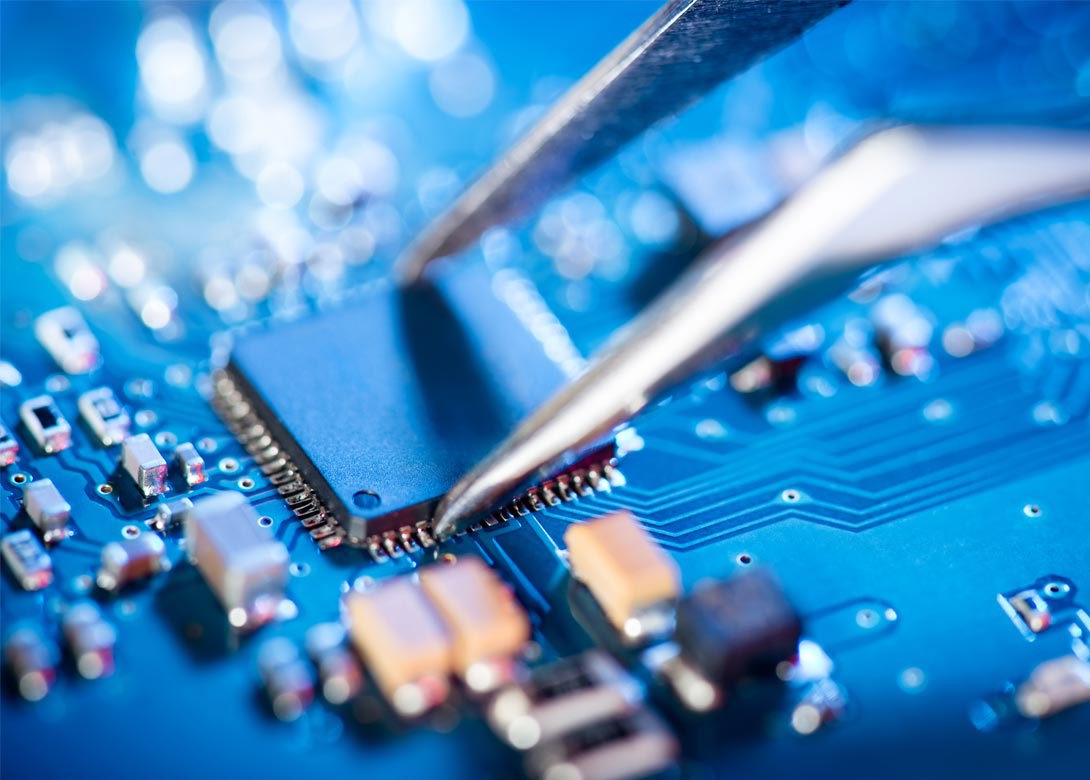

These ambivalent properties are provided by the materials’ crystal lattice structure, which needs to be free from impurities. In fact, even the slightest imperfection or contamination can alter their ability to carry electricity, heavily affecting the performance of the end products - the electronic devices.

As a result, one of the main features of the semiconductor manufacturing market are the incredibly stringent component requirements, in order to obtain products that are free from impurities and thus function properly.

In fact, it is necessary to carry out production in cleanrooms or protected lab environments, as well as to carry out additional cleaning and put the semiconductors and their components in clean, controlled packaging. In addition, component manufacturing should adhere to “copy exact” requirements, i.e. it is fundamental that the form, fit, function, quality, and appearance of each semiconductors’ components remain fixed.

Furthermore, the production of semiconductors requires highly specialised fasteners, c-class components or other special and unusual parts. These can be challenging to manufacture; thus, they may only be available from a few dedicated suppliers.

On top of that, the speed of chips and microprocessors is constantly increasing along with new and improved functionalities, standards and features. As a result, these products have short product lifecycles, thus the semiconductor industry has highly variable cycles, with fluctuating peaks and troughs in production. More precisely, the first and fourth quarters of the year are generally characterised by a steep increase in semiconductors’ demand, while sales fall during the second and third quarters. These fluctuations are amplified at the initial stages of the supply chain, due to the bullwhip effect, making the provision of components for semiconductor manufacturing even more challenging.

All these factors, combined with the common supply chain challenges such as maintaining compact Bill of Materials (BoM) and supplier networks, make the procurement of components for semiconductors particularly difficult. In these situations, highly skilled supply chain experts, such as Optimas, are the game changers that can turn these challenges into opportunities for business growth.

Case study 1: Adapt to fluctuating supply demands

A leading semiconductor manufacturer and vendor faced a heavy 60% increase in product demand. Thus, one of its priorities was to keep its production running by ensuring a constant supply of highly specialised, sensitive, “copy exact” components to its three production lines in Asia. These parts required were so special that only a few manufacturers and suppliers located in the U.S. were able to produce these specific parts and have the relevant certifications.

The challenges experienced by the manufacturer were tackled by establishing a close relationship with its supply manager, Optimas. Rhett Tyler, Regional Account Manager at Optimas explained: “Optimas was the ideal candidate. The company was selected due to a proven track record of supplying specialised fastener solutions to high-tech and semiconductor OEM manufacturers worldwide. The business operates a vast component portfolio that includes highly specialised components, and it is backed by a highly efficient global logistics network that can integrate cleanroom and other specialist practices.”

In order to address the market fluctuations and provide a reliable supply of components at all times, the customer, Optimas and the certified component supplier met weekly. This facilitated round-the-clock response and the option to divide up deliveries to be received and sent. This responsive approach also allowed the semiconductor manufacturer to grow its business while delivering high-quality, repeatable, and reliable products.

Optimas’ delivered a vendor-managed inventory (VMI) to supervise the supply, cleaning and packaging operations in the US, and ensured that the manufacturer could receive a flexible flow of certified, cleaned semiconductor components to its three production lines in Asia.

Case study 2: Reduce the supplier base for lean production

In addition to requiring a flexible yet reliable supply of cleanroom certified, stainless steel parts with highly specialised platings and coatings, semiconductor manufacturers share the same requirements of supplier consolidation as other industries.

This may appear counterintuitive, given the limited number of certified manufacturers and suppliers of specialised components for semiconductors. However, the simpler the Supply Base Management (SBM) is, the easier it is to control the entire supply chain.

A premier semiconductor manufacturer in Asia Pacific, which provides its solutions to two of the top 5 producers and suppliers of semiconductor processing equipment, was looking to consolidate its network of over 30 suppliers in order to improve the production efficiency.

Therefore, Optimas needed to ensure a reliable supply of difficult to get, highly specialised clean components, even during peaks in demands, from a lower number of suppliers.

To help the manufacturer succeed in such an ambitious project, Optimas conducted a thorough assessment of the manufacturer’s needs, in terms of specialised components, certifications, cleaning standards and locations to serve. In this way, Optimas and the manufacturer were able to reduce the number of suppliers from 30 to 1. By providing a single source of procurement, the semiconductor manufacturer was able to reduce costs, simplify the administration and optimise the productivity and time-efficiency.

“The successful collaboration with the manufacturer has been going on for over 20 years. Optimas is a knowledgeable supply chain expert that understands well the requirements in the semiconductor market and provide an efficient global service,” commented Jocelyn Zhou, key account manager (BDM) at Optimas.

Addressing the needs of the industry

Semiconductors are a mainstay, as they are key to the technological developments across all sectors, including medical device and cell phone industries. However, as the high-tech market advances, the specifications for these materials will become stricter and more demanding.

This means that supply support for the semiconductor market, which is already particularly challenging, will become even more onerous. Semiconductor manufacturers will require higher volumes of specialised fasteners that meet standards for quality, “copy exact” and cleanness, whilst still expecting flexibility and reliability from the supply chain. Without proper preparation and support, these challenges could undermine the success of semiconductor manufacturers. However, by partnering with experts in logistics and supply, such as Optimas, manufacturers can not only solve their most incumbent issues e.g. consolidate their inventory or supplier base, but also improve the overall production system, boosting quality, efficiency, productivity and profitability.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.