Consumer wearables, including smart watches and augmented reality glasses, are gaining in popularity, as well as other important markets such as medical and healthcare. State of the art wearables have to have good reliability, precision and are compact. Here, Peter Swanson, managing director of adhesives specialist Intertronics, discusses the best practice for dispensing processes in wearable device manufacturing.

The comfort, flexibility and connectivity of wearables have been made possible through progress in sensor technology, power management and transmitter technology; these advances in wearable technology require improvements to the production process. One important part of the assembly process is the dispensing of materials such as adhesives, silicones, thermally and electrically conductive materials and greases.

Dispensing technology is required for numerous functions when manufacturing a wearable device, such as bonding batteries to the housing, the application of conductive pastes for thermal management, and the sealing, encapsulation and bonding of sensors. Many Micro-Electronic-Mechanical Systems (MEMs) are bonded or encapsulated with a suitable adhesive, and materials are also used to coat or underfill processors, attach and bond RF-modules and seal and bond actuators.

When manufacturing a medical device, it is important that all processes are reliable, consistent and can be validated. The industry requires manufacturers to have a good understanding of process variables, and to control them to create a robust procedure across all dispensing processes. Dispensing processes must be done accurately and repeatably.

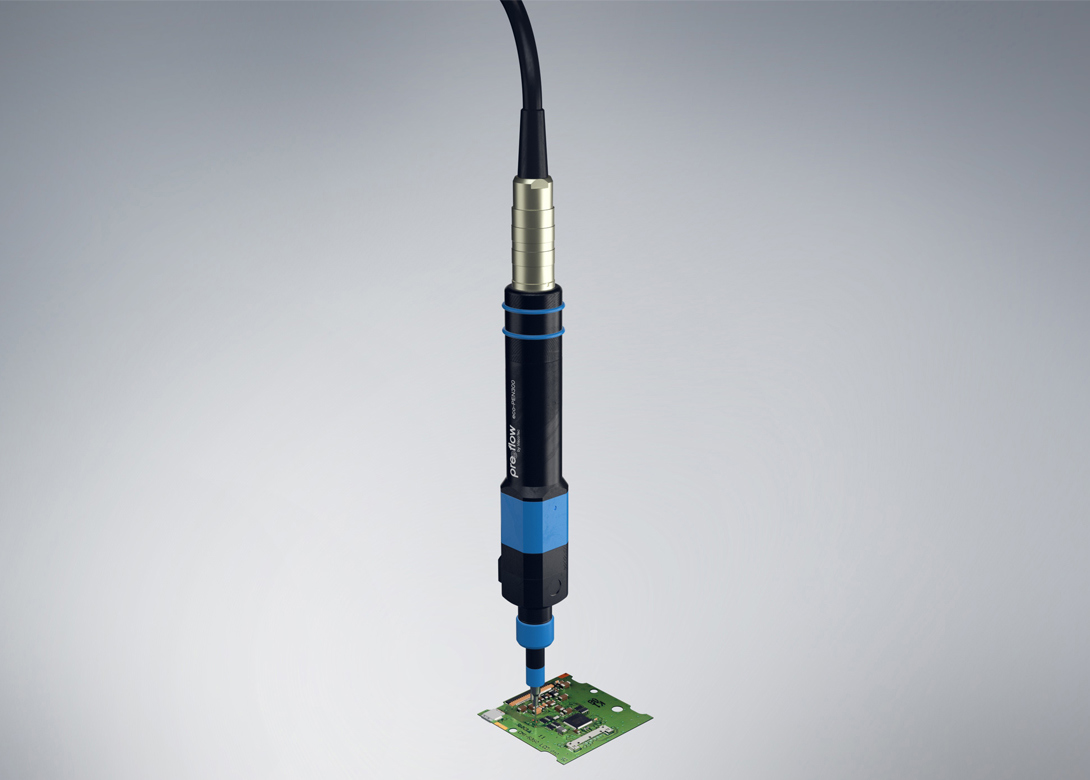

To achieve the level of precision required, manufacturers can opt for progressive pump technology, as it enables true volumetric dispensing. A progressive cavity pump typically consists of a single-helix metal rotor and a double-helix hole in an elastomeric stator, which forms a sequence of small discrete cavities. These cavities progress through the pump as the rotor is turned, transferring the liquid. The output represents true volumetric dispensing - the amount of material is directly proportional to the number of rotations of the rotor, and is not affected by material viscosity, input pressure or ambient temperature.

One example technology is the eco-PEN330 preeflow dispenser, which enables the user to dispense volumes as small as 0.001µl within 1%, 99% of the time - a high-level of repeatability and accuracy. It can be used for low or high viscosity materials, with or without filler content.

Dispensing for diabetes management

Medical wearable devices have huge potential for diabetes management. For example, in the US, the digital diabetes management market size has a compound annual growth rate of around 20%. Examples of technologies include continuous glucose monitoring, smart glucose metres and closed loop systems.

One interesting example comes from a client of ViscoTec India, whose engineers created a closed loop system, consisting of a skin patch that measures blood glucose levels, a device that calculates the required insulin dose, and a smart pump that injects the dose. During the production process, the manufacturer required the precise dispensing of 0.7ml of grease into a gearbox component of the electric motor in the insulin pump. These precise requirements were fulfilled with a preeflow eco-PEN330.

In most wearable production processes, adhesive dispensing is automated to achieve a high degree of repeatability. Once the dispensing technology has been selected, manufacturers can repeat the application of materials with positional accuracy by incorporating a robot or other form of automation. Medical device manufacturers have several options to mechanise the process, which include rotary tables or simple 3 axis benchtop robots, usually at modest cost, right up to multi-axis robots with vision-based control and feedback.

As well as delivering productivity benefits from their speed, consistency and ability to run continuously, automation can enable results not possible manually. They can deliver rapid return on investment, particularly when precision and accuracy-based productivity gains are taken into consideration.

The use of wearable technology in consumer and healthcare applications is now widespread. To produce a compact, reliable and precise device that meets rigorous industry standards, manufacturers require a robust dispensing process. Working with an experienced adhesives and dispensing equipment supplier can help you to invest in suitable technology.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.