Advanced Driver Assistance Systems, commonly referred to as ADAS, are becoming far more common in modern day vehicles. The current adoption rate of 20% is expected to grow dramatically over the next few years, as new technologies deliver greater levels of safety.

Cooperation between cameras, radar and Light Detection and Ranging (LiDAR) systems, as well as multiple ultrasonic sensor systems, are the key factors in enabling ADAS functionality. These technologies work together to identify objects, pedestrians and potential hazards for the driver. In some cases, these technologies even take independent action to keep drivers, passengers and pedestrians safe.

In particular, the camera component is essential. Today’s automobiles incorporate more and more cameras – and types of cameras. The reliable performance of these optical systems is crucial because the safety of the driver often depends on them.

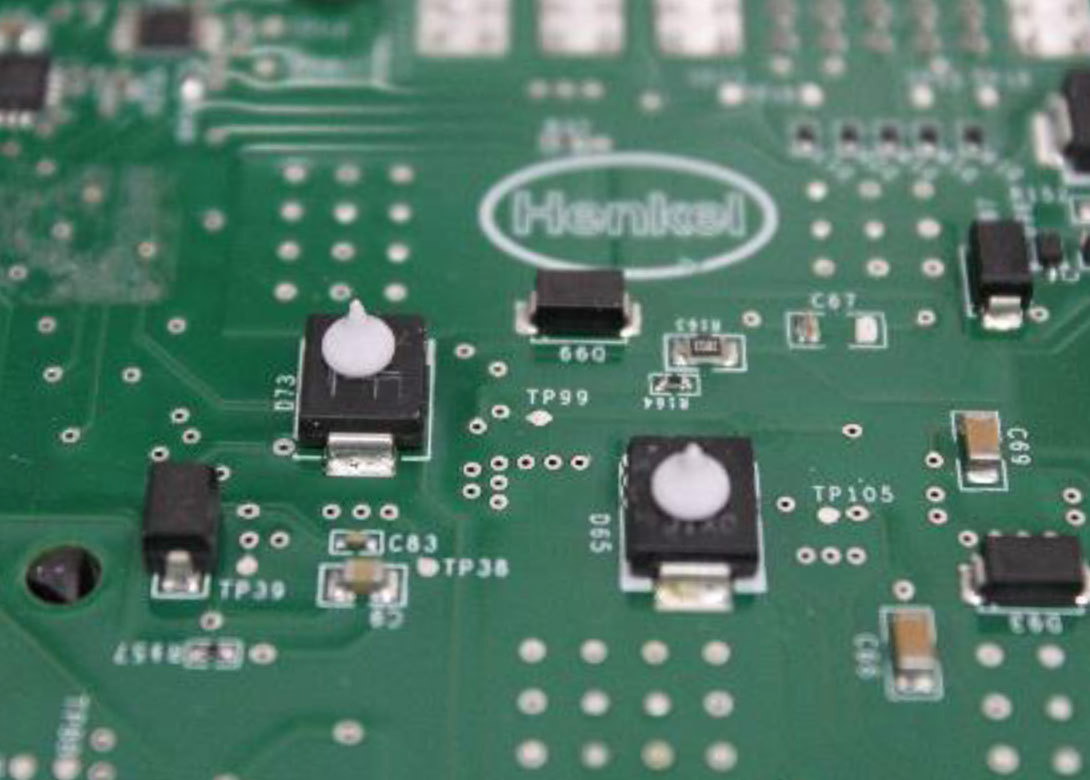

Henkel’s BERGQUIST® brand offers a comprehensive range of high performance Thermal Interface Materials (TIMs) that meets a uniquely wide variety of heat dissipation requirements and manufacturing preferences.

Henkel offers several RoHS-compliant products for manufacturers who prefer traditional thermal gels. When used in high performance applications, Henkel's BERGQUIST gel range offers immediate functionality throughout the life of the product. In addition, gel products provide excellent surface wet out, and can be used to fill gaps or voids easily.

This makes them a particularly viable solution for devices that have issues related to flatness or coplanarity. These innovative thermal gels from Henkel come in both silicone and silicone-free chemistry with packaging options ranging from cartridges through to bulk containers. Henkel's BERGQUIST gel range offers high performance and high reliability with robust processing options.

Bergquist Liqui Form TLF 3500CGEL is a silicone-based one component 3.5 W/m-K liquid that is designed to cure in place unlike traditional thermal gels. This new class of gel combines the high reliability of two part liquids with the ease of use of one part gels. It was designed to meet applications that demand high throughput, gap stability in vertical orientation, and high reliability in harsh aging conditions.

The material has low viscosity for easy flow and wetting in electronic assemblies, and has form stability to reduce slump and sag of the liquid during handling. The rheology and adhesion characteristics of this material give it vertical gap stability during the storage, handling and operation of devices. Excellent long-term reliability in thermal cycling, high temperature and humidity is achieved when cured to a soft, solid material. Adoptive curing chemistry allows the material to cure under ambient and accelerated cure schedules. This gives manufacturers the flexibility to organise their cure schedule based on their specific application need.

TLF 3500CGEL’s one part chemistry provides significantly lower Total Cost of Ownership (TCO) when compared to traditional two part chemistries. It achieves this by reducing dispensing equipment complexity, equipment cost and consumable parts (static mix tubes). Its one part chemistry requires no static mix tube, which allows the dispense head to get closer to the workpiece to provide a robust dispensing process. Although TLF 3500CGEL is a premixed formulation, there is no need for frequent purging as with two-part formulations. This reduces material waste and improves throughput by eliminating frequent line stops and starts.

The rheology of TLF 3500CGEL has been formulated to enable fast coverage of large interface areas, as well as precision placement of small dots and lines. However, unlike traditional gel solutions, this new class of gel from Henkel’s BERGQUIST brand balances excellent dispensing rheology with outstanding form control. This means it resists slumping or creep, and lines and dots maintain their form even when stacked vertically during processing. This gives manufacturers greater flexibility when designing assembly sequences. TLF 3500CGEL can even be inverted upside down for dispensing on double-sided substrates or modules.

The tailored rheology of TLF 3500CGEL also makes it possible to dispense it continuously over three- dimensional surfaces such as cast housings or certain cold plate designs. After it has cured, the gel functions equally well over a large range of gap sizes (0.5mm to 3.0mm). This is particularly valuable for manufacturers using boards with mixed topologies or varied gap sizes.

TLF 3500CGEL is a one part formulation that is recommended to be stored frozen until use to achieve long shelf life. Once on a tool, the material performs consistently for several days at room temperature without the need for cooling the tool. Application temperatures as low as 50°C will accelerate the reaction and reduce the time required to cure.

TLF 3500CGEL can be dispensed using multiple dispensing technologies, such as precision screw pumps, piston pumps, positive displacement pumps and time pressure pumps. Based on the application target weight or volume, a wide range of nozzle sizes can be used to achieve the target weight. Nozzle sizes ranging from 1.3mm ID to 5.0mm ID have been shown to provide stable and repeatable shot weights.

The outstanding dispensing capabilities of TLF 3500CGEL enable all applications to be combined into a single dispensing and assembly station, including double-sided applications. TLF 3500CGEL can be oriented vertically without sliding or creeping out of position. This function of the unique rheology of TLF 3500CGEL enables effortless dispensing while maintaining its form, even when working against gravity.

ADAS systems combine LiDAR, radar and camera modules to provide an extensive range of functions. Each of these modules uses multiple discreet and integrated components to accomplish form, fit and function. TLF 3500CGEL is a key ADAS enabler that is paving the way toward the vehicles of the future by providing:

- Higher thermal densities due to high thermal conductivity (3.5 W/m-K).

- Three-dimensional orientation of features due to its unique rheology.

- Reduced complexity because of its proven, reliable one-part formulation.

- Void-free coverage of large area interfaces between high-power components and cold plates or heat sinks.

- Thermal conduction and protection at module edges in the form of long, void-free continuous lines.

- Precision dispensing of dots onto individual components.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.