There’s nothing more annoying than a screw that can't be undone bringing the job to a halt. As understandable as the urge may be to use excessive force, it’s important not to overdo it – a screw that is stuck can rarely be removed using force. Here, Stahlwille outlines the proven methods for loosening stubborn fasteners.

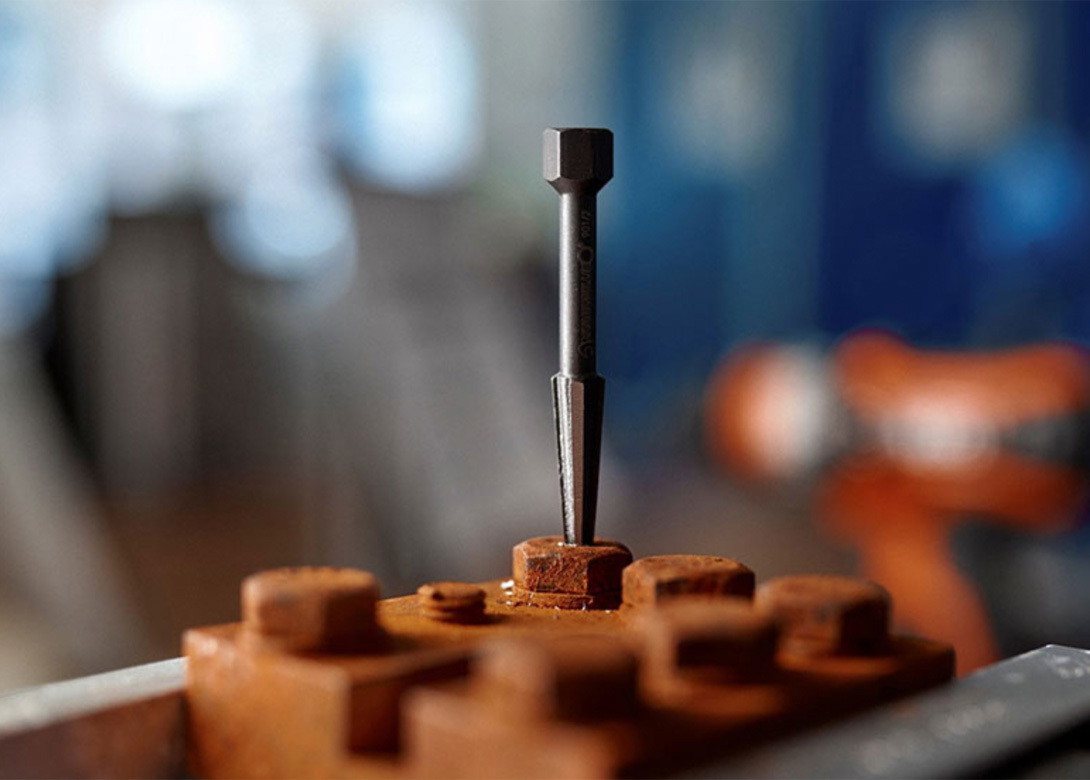

One proven method is penetrating oil. Penetrating or multi-oils usually have very low viscosity, which allows them to penetrate deep into the thread to reduce the friction between the screw and the thread. In order to loosen the fastener, apply the oil as precisely as possible around the screw head, being sure to use the straw provided for this purpose rather than just spraying it across a large area. It can take several hours for the oil to penetrate far enough, so allow for sufficient time before repeating this procedure. In particularly stubborn cases, Stahlwille recommends letting the oil take effect overnight.

The second method – ice sprays – exploits the physical properties of metal, since metal shrinks when it is cooled. Spray an ice spray onto the screw – this will cause shock freezing which breaks up the microstructure of any rust that may be present, and makes the screw shrink due to the cold temperature. After icing, a multi-purpose oil or penetrating oil should be applied to provide additional lubrication when removing the fastener.

If the materials are heat-compatible, professionals can use a hot air gun or blowtorch to try heating the screw joint. The principle is the same as for the icing – the only difference being that the material will expand instead of shrink. Once the screw joint as cooled slightly, the fastener should then carefully be loosened. If additional lubrication is required, a penetrating oil should be applied once the fastener is sufficiently cooled.

Rust remover can also help when trying to remove stubborn screws. If there is visible heavy rust, it often helps to use a special rust removal product. Rust removers penetrate deep into the thread and break up the structure of the rush. However, Stahlwille highlights that, if the rust remover does not contain a lubricating or conditioning component, professionals should always lubricate with penetrating oil after every quarter to half turn to prevent damage to the thread from abrasive rust particles.

If the nut is twisted or the screw head is damaged, it’s unlikely that the screw can be removed without the aid of special tools, so using a screw extractor or nut splitter may be necessary. The screw is drilled, then a screw extractor is driven into the newly made hole, thus replacing either the damaged profile or damaged screw head. If the edges of a screw head or nut no longer provide a firm grip for a ring spanner or open-end spanner, a nut splitter can be used. This is placed around the nut or screw head, fixed in place, then used as a force loading point for loosening the head.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.