For almost 60 years TOGE® has focused on developing and producing anchor systems tailored to the needs and wishes of its customers, with the company continuously working on developing new products.

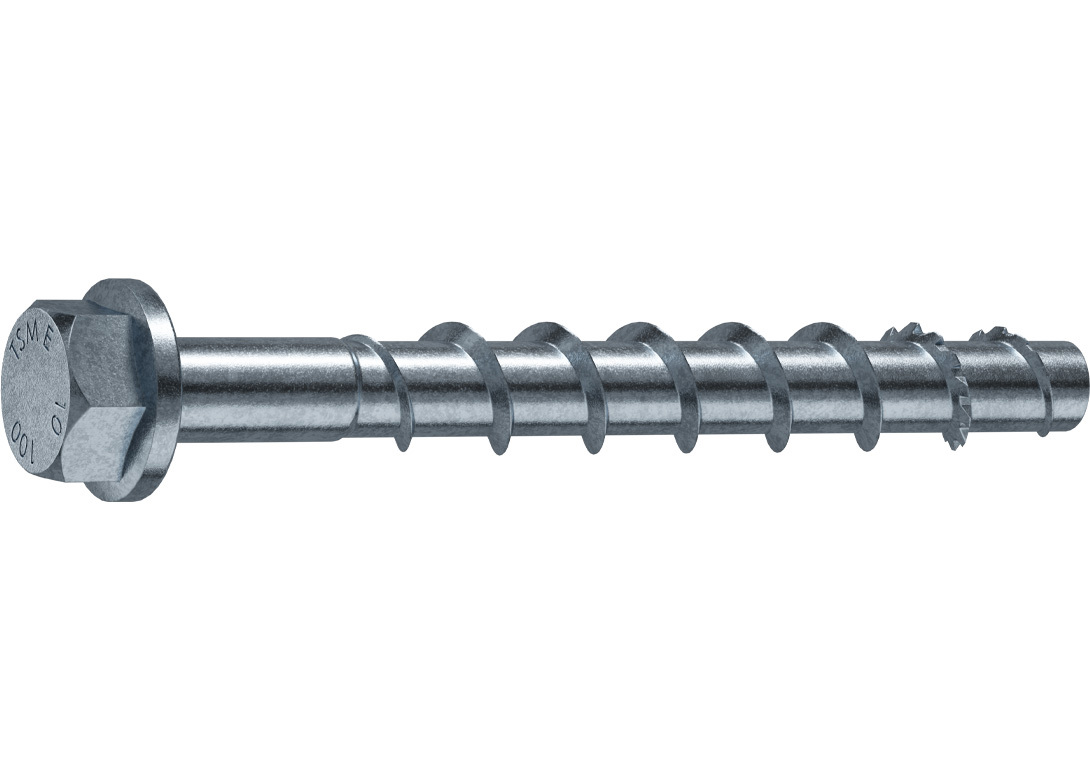

TOGE®’s ability to introduce new innovations into the market is underlined by the introduction of the upgraded TSM high-performance LT A4 stainless steel concrete screw, which has been designed for even smoother processing and boasts top tier quality with an ETA certification. It is also available in various sizes and head shapes to cater to the diverse needs of customers.

TOGE® is also on the brink of introducing two more innovative products to its line-up – the TSM Multiground, a unique internally threaded screw capable of being flush-mounted into concrete surfaces to help simplify tasks such as ceiling suspensions, as well as the TSM Eco concrete screw, an economical choice tailored for applications not requiring the highest load capacities – providing a cost-effective solution for various fastening needs.

“The TSM Multiground is available in M6, M8 and M10 thread sizes and offers users a compelling alternative to conventional

drop-in anchors – helping to streamline work processes and providing substantial time savings,” explains Niklas Barlovitz, head of product management at TOGE Dübel GmbH & Co KG. “Initially, the TSM Multiground will come with an ETA for concrete as a multiple fastener, with plans to extend testing to other substrates such as masonry, aerated concrete, and even wood, in the near future.”

Niklas adds: “As for the TSM Eco concrete screw, this will be offered with a hexagonal head in sizes M8 – M10, with a countersunk version to follow. Another major benefit of this product is the adapted manufacturing process, which results in a CO2 saving of 700g per kilogram of screws produced.”

With these new products, as well as its wide portfolio, TOGE®’s foremost commitment is to provide its customers with secure and high-quality solutions. That’s why all its safety critical products come equipped with exceptionally high grade certifications, sometimes even boasting up to five different approvals spanning various applications within a product range.

“It is imperative that our products undergo monitoring by an independent authority to ensure safety and quality. The testing procedures mandated by various guidelines guarantee that approved products conform to the specified fields of application and performance parameters outlined in the certification,” underlines Niklas. “Consequently, we continuously invest in obtaining new certifications to uphold these standards. For our customers, these premium certifications serve as a true distinguishing factor when it comes to assessing quality and safety. We understand that in an ever evolving market, trust and confidence in products is paramount. Therefore, we take pride in our unwavering dedication to providing secure and top tier solutions, backed by rigorous testing and multiple certifications.”

To further guarantee the quality of its products, TOGE® has also continuously invested in its production and administration buildings, as well as a new modern testing laboratory and further machinery at its Nuremberg site – in order to expand its capacities. “This puts us in an excellent position to continue developing, testing and producing high-quality products in Germany in the future,” points out Niklas. “As part of the Würth Group, we also have access to the newly built Reinhold Würth Innovation Center – Curio, which was completed last year with an investment of €75 million. In addition to our own facilities, this provides us with a further wide range of testing and development opportunities.”

In addition to its expertise in concrete screw technology, TOGE®’s product portfolio includes a wide range of solutions, such as insulating anchors and insulating screws – designed for securing insulation panels in underground garages or basement ceilings. Additionally, TOGE®’s product line includes aerated concrete screws, purpose-built for aerated concrete applications, along with distinctive offerings such as asphalt screws and specialised products tailored for road and railroad construction needs.

“We take immense pride in consistently delivering to our customers top tier ‘Made in Germany’ approved products, whilst maintaining an unwavering commitment to quality,” states Niklas. “In addition, we can provide complimentary software for calculating concrete screw loads and we can offer customised product solutions to meet virtually any customer requirement. Moreover, we offer the option of presenting our products under private label branding, and we facilitate approval transfers for added convenience.”

Niklas concludes: “We are witnessing a clear shift away from traditional fastening systems in favour of concrete screw solutions. With our existing product line-up, we are well prepared for the upcoming years and thanks to our commitment to ongoing innovation – exemplified by the latest offerings of TSM Multiground and TSM Eco – we are empowering users to achieve higher speed and efficiency, attributes that are poised to gain even greater significance in the future.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.