Bonded anchors have earned an enviable reputation as problem solvers due to their unique combination of strength and versatility. Here Robert Chudzik, category manager at Rawlplug S.A, explains why bonded anchors are the most versatile of all anchoring technologies.

Usually a resin bond is stronger than the base material and ultimate strength is governed by the anchor rod specification. Bonded anchors can also offer stress free anchorages, which will not damage weak substrates and can be placed closer to edges and to each other than other techniques. With care, most bonded anchor systems can be installed overhead and some can be installed underwater – while many are suitable for installation, and use, in permanently damp applications. Formulations are available that offer fast or slow curing rates for a variety of uses including winter or summer use.

With these types of anchor, resin is inserted into pre-drilled holes bonding the fixing element – e.g threaded rod – to the substrate and once cured the fixture can be assembled. Rawlplug products generally consist of two resin components and when mixed, cure to form a very hard material that bonds the fixing element to the hole wall. Resin is only part of the anchor and the complete product includes one of the following fixing elements – threaded rod, rebar or internally threaded sockets.

Their wide range of applications make bonded anchors one of most versatile of all anchoring technologies. Some can be used in seismic zones, cracked concrete, natural stone, aerated blockwork, solid masonry, masonry with perforations and bridge cavities when used with mesh sleeves. Unlike traditional expansion anchors and drop-in anchors there are no expansion forces. Therefore, when anchorage design stipulates smaller edge and/or spacing distances, and design actions are high, resin bonded anchors are often the only choice of anchoring technology. Examples of application fixtures are racking systems, structural steelwork, balustrades, curtain walling, bracketry for pipe supports, barriers, cladding restraints, masonry supports and fixing down machinery.

Resin bonded anchors installed into concrete or masonry function in three ways – adhesion (chemical bonding), cohesion and mechanical interlock. Adhesion is the linking of molecules between the resin and the contact surfaces; cohesion is the linking of molecules within the resin; and mechanical interlock is equally influential on the strength of a bonded anchor and occurs on the resin/fixing element interface and the resin/hole surface interface. Hole surfaces are never perfectly smooth and this is important as it provides additional mechanical interlock. Mechanical interlock is reduced with diamond drilled holes, so it is important to check the ETA or TDS to assess if bond resistance is reduced or if this drilling technique is allowed.

Resin bonded anchors are also covered by ETAG 001 Part 1 ‘Anchors in General’, Part 5 ‘Bonded Anchors’ and EOTA Technical Report number 29 (TR029). The design method in TR029 is valid for all types of resin bonded anchors in concrete with the exception of

post-installed rebar connections, however, it does cover rebar as an anchor. Post-installed rebar connections are assessed against EN1992-1-1: 2004 (EC2) and TR023. EC2 design concept is different from the EOTA EAD design methods and as the applications are more limited (e.g only tension loads and no concrete cone failures), less testing is required and the maximum design resistance is given for different concrete strength classes. Resin bonded injection anchors in masonry are assessed against ETAG 029 and the certification covers solid masonry units and hollow masonry (with mesh sleeves).

Resin anchor formats

There are a range of resin anchor formats, such as:

Injection cartridge systems

With injection cartridge systems, resin components are contained in two separate chambers of a cartridge. They are mixed together by a series of vanes in a mixer nozzle as dispensed from the cartridge. Mixed resin immediately begins to cure therefore nozzles have to be replaced once the working time has elapsed.

A significant advantage of cartridge systems is that the same resin cartridge can be used to in a very wide range of installations –10mm – 40mm hole diameters dependent on threaded rod/rebar diameter – and very deep embedment depths e.g 2.5m with R-KEXII and post-installed rebar. Special mesh sleeves retain resin in hollow blocks and perforated bricks. With each fresh cartridge some resin must be expelled to waste, until an even colour is achieved – demonstrating that proper mixing is taking place.

Cartridge free systems (CFS+)

The Rawlplug CFS+ system uses a soft foil pack instead of a hard plastic cartridge. The same polyester and vinylester resin formulations are available with the advantages that they are more economical for larger projects, as well as reduced environmental impact as there is less waste.

Capsule systems

Capsule systems contain precise quantities of resin and hardener with the hardener contained in a separate phial sealed within the outer capsule. The resin also contains a quartz aggregate, which improves the strength of the resin and can be likened to aggregate in concrete. Precise capsule volumes necessitate specific hole diameters and depths, therefore, unlike cartridge systems, a range of capsule diameters are available for predetermined hole depths.

Spin-in capsule systems

Spin-in capsule systems are the original resin bonded anchor and require a special threaded rod with a chiselled point to mix the resin and hardener – as it is driven through the capsule. The driving action must be spinning with this type, hence the name spin-in. The special threaded rod also has a hexagonal driver and is installed using the rotary action of a drilling machine.

As standard rebars do not have the special chisel point and driver required to install spin-in capsules, hammer-in capsules were developed. However, as the installation is relatively simple Rawlplug’s R-HAC-V hammer-in capsule is also suitable for installations with threaded rod, although care should be taken not to damage the end of the thread during hammering. R-HAC-V hammer-in capsules are directional, i.e the catalyst is only at one end of the capsule, which must be placed toward the outer end of the hole. The capsule has an arrow indicating which way the capsule should be inserted.

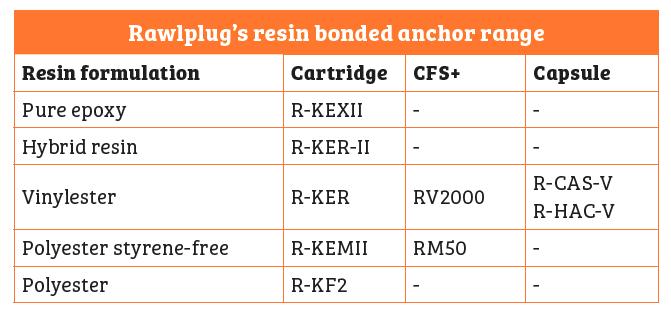

Rawlplug uses resins of various formulations such as polyester, vinylester (epoxy acrylate), pure epoxy and hybrids. Formulation of hybrid resin is a mix of organic (resin) and inorganic (cement), with the benefit of higher bond resistance (adhesion) in less well cleaned holes. Resin also contains a quartz sand and this acts like aggregate in concrete improving the strength of the resin. Rawlplug’s resin bonded anchor range is made up from two basic resin types – those cured by a catalytic action, chain growth polymerisation, as well as those cured by direct mixing of the components, step growth polymerisation.

Chain growth polymerisation describes a catalyst initiating the curing of the resin itself. Proportions of catalyst and resin do not need to be precise and a catalyst is not required to be mixed with all of the resin. A chain reaction will propagate through the mix as long as most of the base resin is exposed to some catalyst. This happens automatically with capsule and injection systems.

In a step growth polymerisation, the two resin components will cure only in direct contact with each other. Curing does not spread through the resin, as with catalytic resins, so mixing must be thorough and proportions correct. Epoxy resin, sometimes referred to as pure epoxy should not be confused with epoxy acrylate R-KEXII is the only step growth polymerisation resin in the Rawlplug range and is available as a 385ml or 600ml injection cartridge system. Epoxy resin exhibits very low shrinkage so it maintains a high bond strength in larger holes diameters. Shrinkage of the resin is also controlled by the ETA process where bond strength may reduce as the hole diameter increases.

Installation procedures

Before installation a number of checks must be carried out. These include checking the use by date of the resin materials, the base material temperature, the working (gel) time, as well as checking the availability of necessary equipment. Protective equipment should also be worn as necessary such as eye and hearing protection whilst drilling, eye protection when setting resins overhead, as well as gloves when handling resin systems.

When installing deep embedment anchorages, as with rebar, it may be preferable to use diamond core drills. However, these create some issues for resin bonded anchors. If the hole wall produced is very smooth it generally reduces the bonding ability of the resin. This will lead to a slurry coating the hole wall that requires careful cleaning. Rawlplug recommends flushing with water, then blowing with air followed by the standard brushing technique.

In masonry, attempts at drilling holes should be performed with increasing impact energy. The lowest to highest impact energy includes: rotary only, rotary percussion, SDS-Plus hammer and SDS-Max hammer. This is critical to the performance of any anchor in masonry as the higher impact energies can damage the masonry unit, creating significant spalling of the unit or loosening the brick/block mortar joint.

Drill dust, if not removed effectively, can leave a layer on the hole wall and significantly reduce the bond strength. This varies between products, and resin chemistry, with pure epoxy, hybrid cartridges, and spin-in capsules, generally achieving smaller reductions in performance than vinylester and polyester resins.

Another consideration is storage temperature. Resin bonded anchors should be stored and transported in a controlled temperature environment, generally between 5°C and 25°C. Low resin temperatures increase the viscosity and this increases the force required to extrude the resin. The risk with higher extrusion forces is failure of the dispenser, either the handle/trigger or mechanism. High storage/transport temperatures can age, degrade and dry out the resin – creating some significant risks including increased extrusion forces, poor mixing, as well as significantly reduced shelf-life.

An important temperature during installation is the base material temperature and this can vary significantly depending on ambient air temperature, wind, and if the surface is in direct sunlight or in the shade. It is recommended that a non-contact IR thermometer is used to check the actual temperature in the drilled hole. Rawlplug resins are supplied with temperature charts and show a ‘working’ time and a ‘curing’ time. Working time (sometimes referred to as gel time or open time) is the time the installer has to inject the resin (with injection systems) and insert the metal element. Note: A longer time will be required to install large diameter and/or deep embedment rebars, as it takes longer to fill the holes – especially when multiple cartridges are required.

Curing (setting) time shows the time required (at specific base material temperatures) before the fixture can be mounted and the anchor torqued and loaded. Rawlplug produces resins with slower and faster curing. Slow cure resins are termed ‘summer’ resins and are designed for higher base material temperatures, where anchors can be installed without the resin curing too fast – i.e before the metal element is fully installed. These are particularly useful in countries with higher ambient temperatures or when installing rebar when a longer working time is required. Fast cure or ‘winter’ resins are useful in reducing the time before the anchor can be loaded with low base material temperatures or they can be used for very fast curing at higher temperatures. The main advantage of this is that the anchor could possibly be torqued and loaded within one hour at a base material temperature of 21°C. However, be aware that as working time and curing time are related, winter (fast cure) resins will have very short working times at 21°C – possibly less than two minutes.

There are also a number of problems that can arise when installing a bonded anchor. For injection systems, the resin could not be fully cured, which has many causes. These include not discarding a sufficient volume of resin before pumping the hole; an expired or out of date resin; as well as not using the correct mixing nozzle. A high base material temperature may also not allow sufficient time to install the metal element. However, too low of a base material temperature may prevent the resin from curing or extend the curing time.

It’s also recommended to have a contingency plan in place in case of encountering rebar during drilling (e.g fixture with alternative hole positions). These moments, and offset loading, can result with alternative hole positions in the fixture and any alternative anchorage design must be recalculated to ensure that individual anchors are not overloaded. The engineer responsible for the installation must make decisions regarding rebar, as it may be acceptable to drill through a percentage of rebar. However, if the slab has pre-stressing tendons then it will be unacceptable to drill through these as it will compromise the structural strength of the concrete. Use of a rebar detector is recommended, as avoidance (although not always possible) prevents the complication of redesigning the anchorage.

Insufficient or improper hole cleaning, however, is the most significant risk to resin bonded anchor performance. Issues such as using a worn brush; using a nylon brush when a steel one is specified; not brushing the required number of times according to installation instructions; as well as not cleaning the dust from the bottom before brushing; will all reduce the bond strength of the resin bonded anchor.

No other fixing technology offers the diversity of applications as bonded anchors and this is in no small part due to the wide range of possible base materials. Rawlplug offers bonded anchor systems for non-cracked concrete, cracked concrete, for casting new concrete to old, with rebars, and there are even some resin systems in the process of being approved for use in seismic zones.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.