By Michal Tokarcik, technical manager at Klimas Wkręt-met

On every construction site, at each stage of the works, a decision on the right type of fastenings will occur sooner or later. This is especially true in safety related applications, in which the failure of a fastening may result in the collapse or partial collapse of the structure – causing risk to human life or leading to significant economic loss.

Among the anchors intended for safety connections of structural elements and non-structural elements, to the base materials in medium and heavy-duty applications, are two basic types – mechanical and chemical. The selection and correct installation of an anchor are essential points. Therefore, it is crucial users take into account the following aspects in determining the correct choice:

Among the anchors intended for safety connections of structural elements and non-structural elements, to the base materials in medium and heavy-duty applications, are two basic types – mechanical and chemical. The selection and correct installation of an anchor are essential points. Therefore, it is crucial users take into account the following aspects in determining the correct choice:

- Substrate material (type and class of concrete or masonry – solid or with voids): Depending on the type of substrate a suitable anchor must be selected. Some anchors are approved to be used in numerous substrates, while others are designed for one particular type of substrate.

- Environmental conditions (moisture, presence of chemicals): Atmospheric conditions determine the selection of material or anti-corrosion protection of the anchor. Fastenings located in chemical plants or coastal areas are more exposed to corrosion risk.

- Type of loads: Static, seismic or dynamic.

- Direction of load: Tension, shear or their combination.

- Load-bearing capacity of anchor: The value of loads to be securely anchored determines the selection of the type and diameter of the fastener. The required anchorage depth is also crucial as it provides verifications that the value of design actions (Ed) does not exceed the value of design resistance (Rd).

- Edge distances and spacing between anchors: Reducing the edge distances and spacing is only possible when minimum allowable values smin and cmin and appropriate reduction factors are applied to calculate values of resistance under tension and shear load.

- Installation parameters and additional requirements: Additional requirements needing to be taken into account include concrete conditions – whether its dry, wet or water filled; the type of drilling such as hammer, rotary or diamond; as well as the diameter of the clearance hole in the fixture; and the temperature range during the working life of the anchor.

Mechanical anchors

Mechanical anchors are mostly used to fasten elements to the main structural concrete such as beams, columns and slabs. Post-installed mechanical metal fasteners are placed into pre-drilled holes in the concrete and anchored therein by mechanical means such as friction or mechanical interlock. For post-installed mechanical fasteners, a distinction is made according to their principle of operation.

The most popular type of mechanical fasteners are torque controlled expansion anchors, which have a main advantage when compared to chemical anchors – the possibility of push-through installation. Torque controlled expansion anchors also guarantee high load-bearing capacity combined with easy application and quick installation time. The positioning and securing of even the heaviest elements is also more convenient and simple as it eliminates the need of pre-positioning. The expansion is achieved by a torque acting on the bolt. The tension force applied to the fastener is then transferred into the concrete via friction and, to a limited extent, via keying (mechanical interlock) between the expansion sleeve and the deformed concrete.

Due to more than 30 years of experience in creating innovative solutions and the production of construction fasteners, Klimas Wkręt-met has designed the LE torque controlled mechanical anchors, which allow a significant reduction of installation parameters such as minimum spacing, edge distance, as well as minimum thickness of concrete.

The unique design of the LE anchor expansion sleeve, combined with the high strength of the steel, safely transfers the loads into the concrete. Interaction between the bolt’s cone and sleeve enables high load-bearing capacity with ideal tensile stress distribution, so that the anchor can also be used at optimal edge and spacing distances. Groups of mechanical fasteners characterised by deformation-controlled expansion – achieved by hammer blows or by percussion of a machine – are mainly utilised for performing various types of fixings in MEP and HVAC building services and resist lower loads. Bolts or threaded rods are screwed directly into the internal thread of a hammer set anchor.

Another type of mechanical anchor are concrete screws. Concrete screws are screwed into a pre-drilled cylindrical hole and feature a special thread, which cuts an internal thread into the concrete member while setting. The fastening is characterised by mechanical interlock in the concrete thread.

One of the advantages of concrete screws is that they generate much less expanding forces during installation. Load is also distributed across a larger area of the entire length of the anchor. This feature enables even closer edge and spacing distances than torque controlled expansion anchors. The essential characteristics of concrete screws offer fastest installation among all post-installed fasteners as they do not need to be set to a specific torque during installation. Only distance must be controlled to obtain the full contact of the screw head with the fixture while screwing into the pre-drilled hole by using an impact screwdriver. Concrete screws can also be reused for temporary installations, such as anchoring formwork supports. Klimas’ WDB concrete screw portfolio comes with various types of heads, which makes them a versatile product for a wide range of applications.

If a base material is masonry, such as vertically perforated bricks or AAC blocks for non-structural applications, Klimas nylon frame anchors KPS/KPR-FAST are recommended. They are approved according to ETAG 020 in all types of substrates and provide reliable and secure fastening, offering excellent values of characteristic resistance (FRk).

Chemical anchors

Chemical anchors

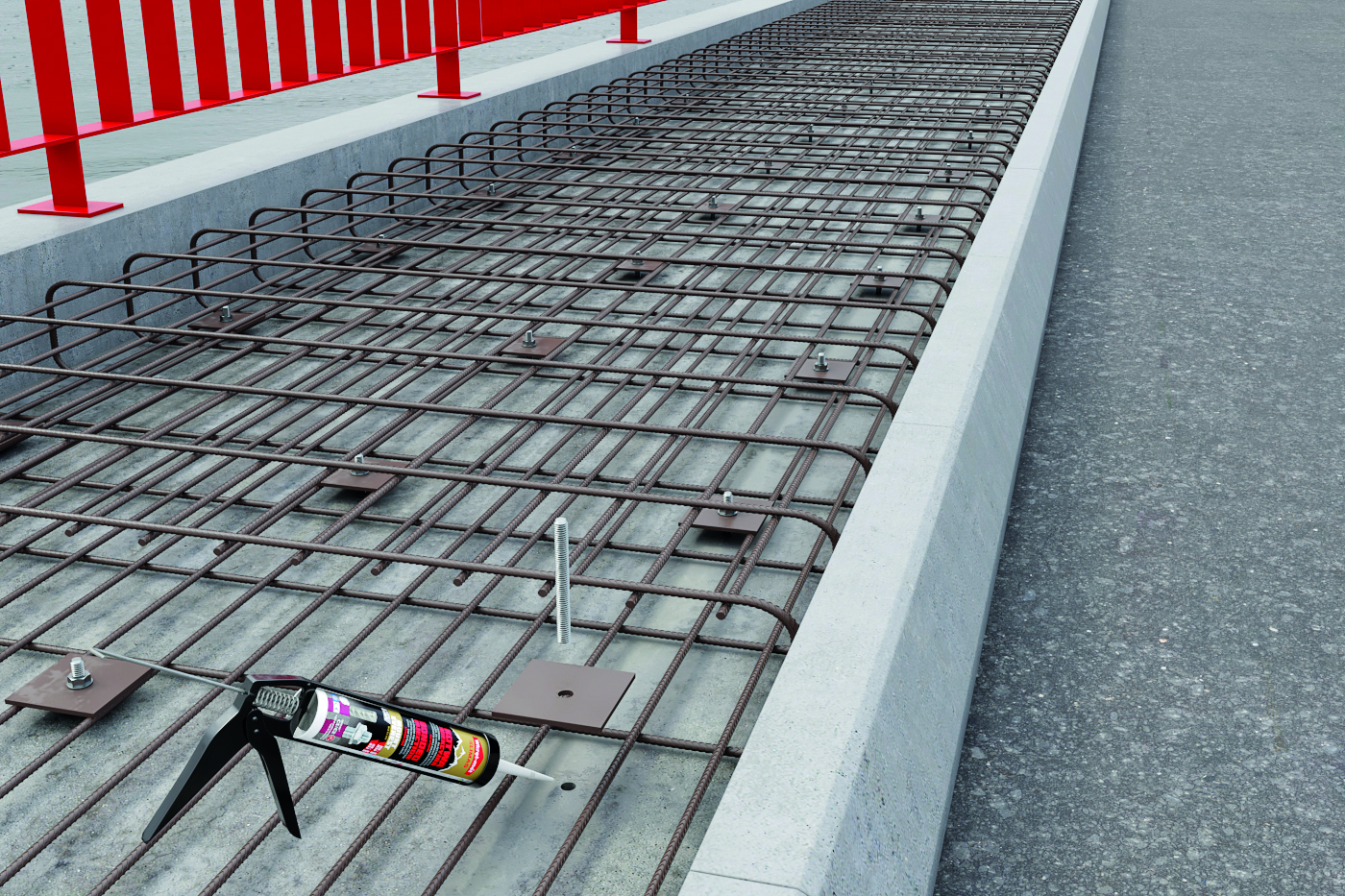

Chemical anchors, also called bonded fasteners, consist of a bonding material and an embedded metal part placed in a pre-drilled hole in the base material. They are anchored primarily by means of a bond. The embedded metal parts used are mostly threaded rods and reinforcing bars.

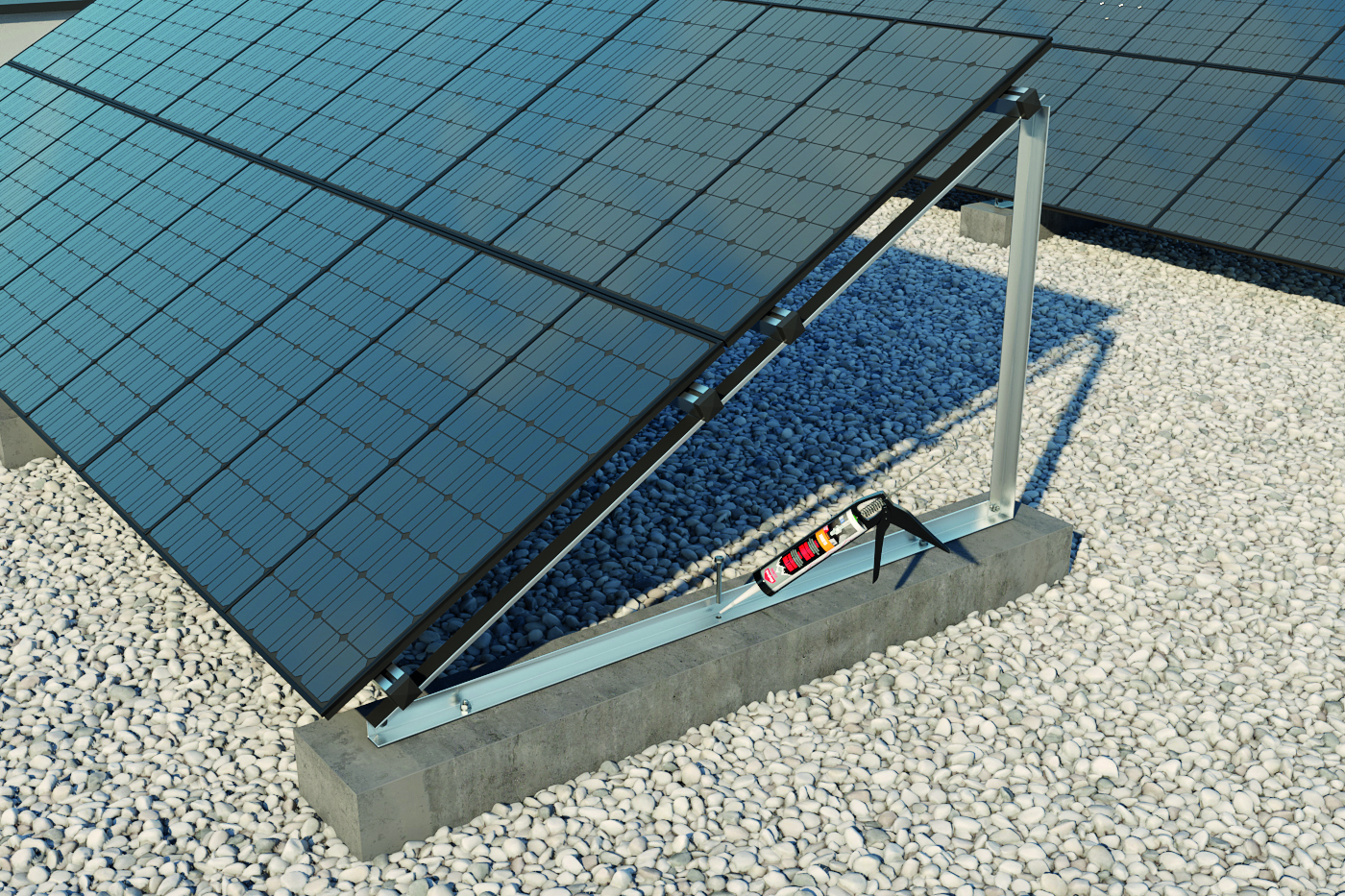

The bonded anchor systems offer a variety of unique benefits compared to mechanical anchoring. By avoiding mechanical expansion, they do not cause installation stress and can also be installed close to each other and to substrate edges. They are also able to resist the highest static loads, with some products also approved for seismic applications, with chemical anchors being the better choice for dynamic applications. Most resin anchors may be used in a wide variety of substrates and site conditions.

Nowadays chemical anchor systems also offer the possibility to be used in dry, wet and flooded holes without the loss of performance. Their non-sag formulation allows overhead applications without specific accessories. Variable embedment depth from 4d to 20d offer versatility in design for shallow and very deep applications and advanced bond strength makes them irreplaceable in applications where action loads need to be transmitted into limited concrete component volume or via base plates with limited dimensions. To match an end user’s installation environment, chemical anchors are available with various curing times which include:

- Normal gel and cure time (standard grade).

- Slow gel and fast cure time for high temperature environments (extended gel time/tropical grade).

- Fast gel and fast cure time for more rapid applications (speed grade).

- Fast gel and fast cure time for cold temperature environments (winter grade).

Types of bonded anchors according to chemical formulations

Klimas offers a wide range of chemical anchors from a classic polymer compound to top of the range epoxy formulations. These include the polyester styrene-free (WCF-PESF) and pure epoxy system (WCF-E3), which each offer a versatile range of applications and benefits.

A chemical formulation can influence many aspects of the behaviour and performance of a chemical anchor. These include resistance to chemicals and corrosive environment, service and installation temperature ranges, resistance to fire, gel and cure times, as well as the load-bearing capacity of the bonded anchor system. Although chemical anchors available on the market can contain a variety of additives to influence some of their properties, Klimas generally distinguishes five typical formulations, which include polyesters, vinylesters, epoxy acrylates, hybrids and epoxies.

Polyester resins

Polyester is a low to medium performance level chemical anchor system. It is a cost-effective, general purpose system with unsaturated polyester as its chemical base. The two component system has been formulated for anchoring in a wide variety of building materials, making it ideal for standard applications in brickwork and hollow brick.

This type of chemistry is a proven and reliable formulation that has been a common choice in the construction industry for over 30 years. It is considered a ‘classic’ chemical combination, which is tried, tested and trusted. The combination of the styrene monomer has historically been used as a reactive diluent and crosslinking agent. Klimas has advanced its technology to remove this and developed an alternative product WCF-PESF (styrene-free) with the equivalent strength properties. The WCF-PESF has reduced chemical hazards and has a very low odour, making it suitable for use indoors and in confined spaces.

Vinylester resins

Vinylester resins

A vinylester resin, also known as epoxy acrylates, is considered a hybrid of epoxy and polyester. It is produced by the esterification of an epoxy resin with acrylic or methacrylic acids, which is why it can also be known as epoxy acrylates. Bringing the best elements of epoxy and polyester together, vinylester resins offer improved performance parameters, fast cure and good low temperature behaviour. These resins have been engineered to generate a higher bond strength, as well as a resistance to a high ph environment, making them suitable for more demanding heavy-duty structural anchoring applications.

The WCF-EASF formulation from Klimas has undergone extensive testing, as well as withstanding C1 seismic conditions and can offer outstanding performance in concrete and masonry substrates.

Hybrid resins

A hybrid system includes a two part chemical anchor with an addition of inorganic fillers to one of the components. It is designed to cure fast so users can load the fastening point earlier than could be achieved with an epoxy anchor. Hybrid systems have similar performance characteristics to epoxy acrylates resins, however the incorporation of inorganic fillers can enhance their properties.

Epoxy resins (pure epoxy)

Epoxy resins (pure epoxy)

Pure epoxy formulations offer the strongest chemical bond as well as excellent chemical resistance. The physical characteristics of the epoxy allow them to be used in diamond cored holes with a smooth surface. Relatively no shrinkage in the curing process also enables epoxy resins to be used in applications with large diameter steel elements to be set at deeper embedment, as well as the filling of larger annular gaps. Epoxy chemical anchors are sensitive to low temperature ranges during installation and the curing process and are therefore generally not recommended for use below +5°C.

Klimas WCF-E3 is a top performance two component 3:1 ratio pure epoxy bonded anchoring system for use in cracked and uncracked concrete under normal as well as very demanding seismic conditions (seismic categories C1 and C2). The anchoring system also enables a wide range of post-installed rebar connections including anchorage and overlap joint applications such as slab to slab at support, overlap joint at a foundation of column or wall, etc.

Choosing the suitable type of fixing for a particular application, as well as knowing the ‘pros’ and ‘cons’ of each anchor group aids the selection process for end-users. In safety critical applications however verifiable calculation notes and drawings must be taken into account, as well as the value of load to be anchored.

Manufacturer’s software such as the KLIMAS DESIGN-FIX can also help to streamline the selection process further. It features an intuitive interface that allows users to input all load and geometry data directly on the 3D drawing. The calculation is then completed in accordance with the latest standards, making it an ideal tool for designers, engineers, project site managers, but also for building owners, developers and contractors.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.