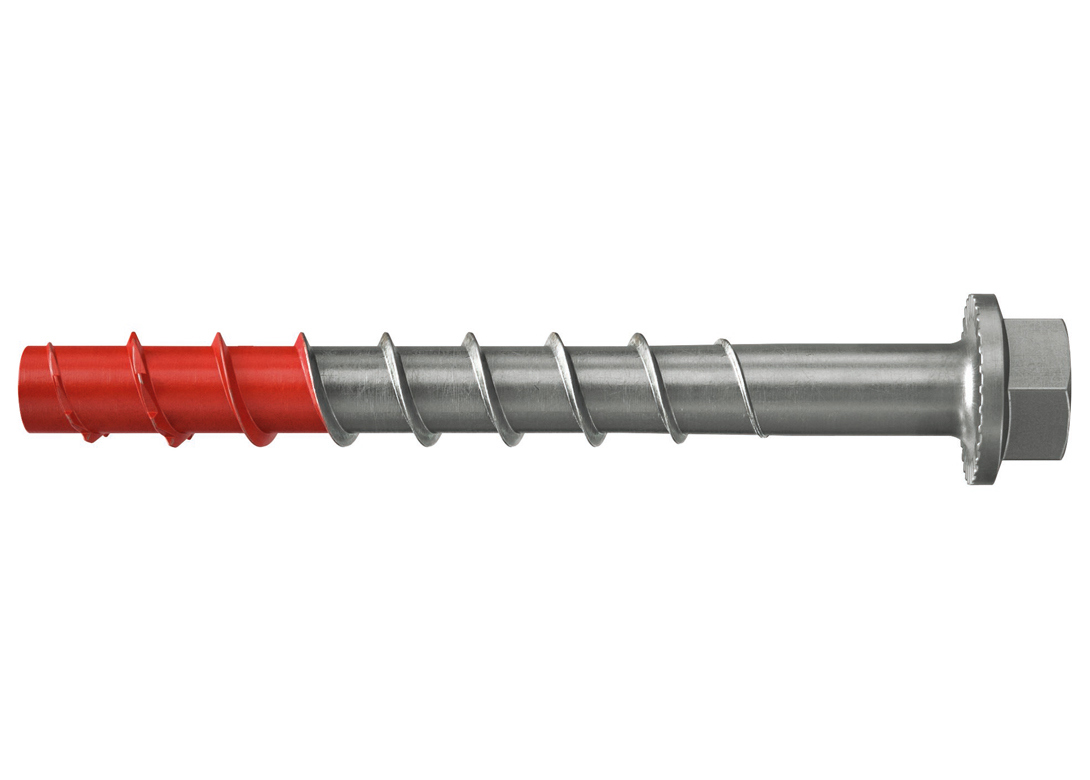

fischer has launched the ULTRACUT FBS II family of screws suitable for anchoring wooden structures into concrete, which it says is suitable for countless wood construction and carpenter applications – whether it be installing support beams, frame elements or roof purlins.

Timber framed structures can also be safely anchored with the concrete screw – the fixing must simply be inserted into the drill hole using the push through installation method and is also suitable for higher loads. In addition to a zinc-plated version, the screw is also available in stainless steel. Depending on its diameter, the fischer ULTRACUT FBS II is also approved for various anchoring depths that correspond to the respective existing load. Different wood component thicknesses can also be processed using fisher’s range of concrete screws.

The fixing can be reused in certain conditions and can therefore be used multiple times with temporary fixings. A measuring sleeve can test the wear of the thread and ensure it still works sufficiently.

The new range includes the ULTRACUT FBS II R stainless steel, suitable for use in wet rooms and outdoors, making it ideal for exterior applications. Additionally, the FBS II 6 also has an Option 1 approval for individual fastenings in concrete. The reduced drill hole depth minimises drilling effort as well as the risk of hitting reinforcements, saving time and costs.

fischer’s concrete screws cover a range of applications through their various diameters of 6mm – 14mm in the zinc-plated versions and 8mm – 12mm in the stainless steel R versions. The patented thread geometry and the large core diameter ensure absorption of high-tensile and shear loads in concrete, allowing applications to be carried out with few fixing points.

The flanks of the FBS II cut deep into the concrete when being inserted. This fit allows the fixing to reliably transfer loads while anchoring itself in the substrate without expanding. It also enables low edge and axial spacing for safe and easy installation. The FBS II can be unscrewed, lined or readjusted a maximum of two times without being damaged, in compliance with regulations. The ribs under the head prevent the concrete screw from unintentionally loosening. No further drill hole cleaning is required during vertical drilling in floors and ceilings or when using hollow drills with vacuum functions.

An ETA assessment guarantees safety during all applications with the zinc-plated or R variant in concrete and includes the fire resistance class R 120. Most variants also include coverage for the seismic performance categories C1 and C2.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.