Every detail of a product’s design is heavily influenced by industrial designers and engineers. They influence how a product looks and functions, material innovations, product ergonomics, end-user benefits and end of life considerations, that’s a lot to think about. Now add into the mix copy or ‘look-a-like’ fasteners and their job can become even more confusing. Here, Star Fasteners looks at how you can ensure a product is genuine and the advantages of these Huck® fasteners

Star Fasteners has years of quality product knowledge and supply, as well as an understanding of customers' applications. The UK-based company works closely with engineers and designers to suggest products that meet the applications constraints and customers’ budgets.

We are often asked for advice on blind structural fasteners and to explain the differences between copy and imported products that essentially look the same as the quality Huck® product range that we stock. We are all very much aware that there are significant variations in the manufacturing process, materials and wire stocks, dimensions as well as quality control. These variations make the ‘same’ product made by different manufacturers very different from one another.

The reliability of structural blind fasteners depends on many factors including, the type and thickness of materials to be fastened, a properly prepared and sized hole and the application itself – where the fastener is going to be used. A well optimised fastener selection can offer many tangible benefits both to manufacturer and end-user and can really make a significant difference in both manufacturing and recall costs.

Huck structural blind fasteners have been installed in many critical joint applications for decades, including widespread usage in automotive, commercial vehicle truck and trailers, aerospace, and agricultural equipment, proving their reliability. The availability of steel, aluminium, and stainless steel (A2 and A4) variations make Huck structural blind fasteners a viable option for joining a multitude of materials, including dissimilar materials such as aluminium to steel, or aluminium to carbon fibre. Furthermore, installation of structural blind fasteners does not require the extensive training required of other joining technologies such as welding.

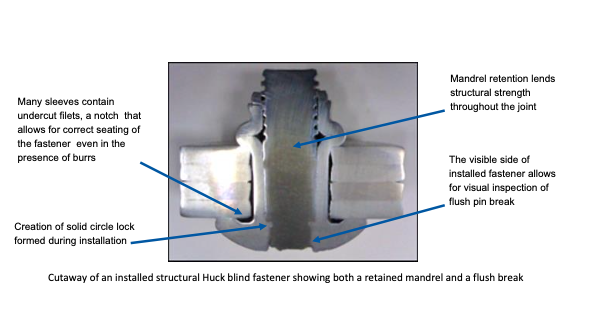

Huck structural blind fasteners install quickly (often in under one second), by a single operator from one side of the material. The visual inspection of structural blind fasteners is based solely on the position of the mandrel break location relative to the sleeve.

What advantages do Huck fasteners give?

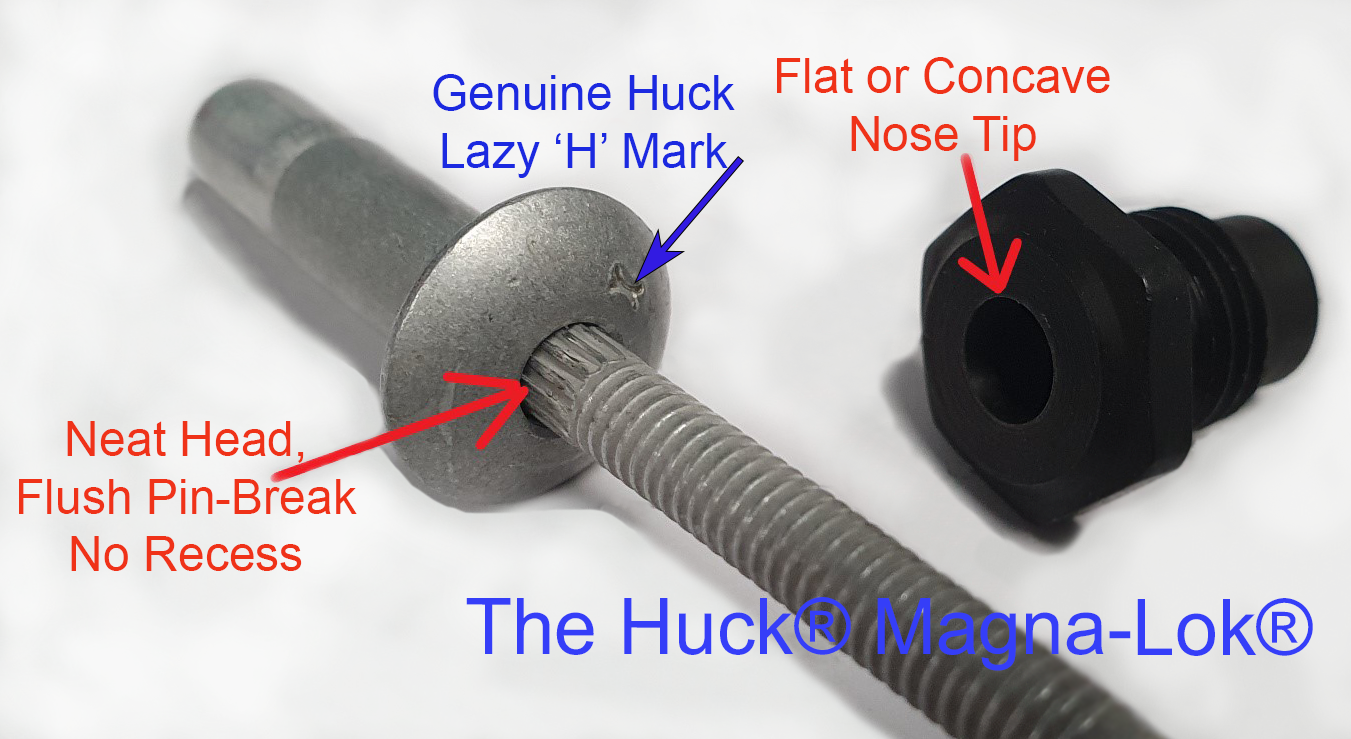

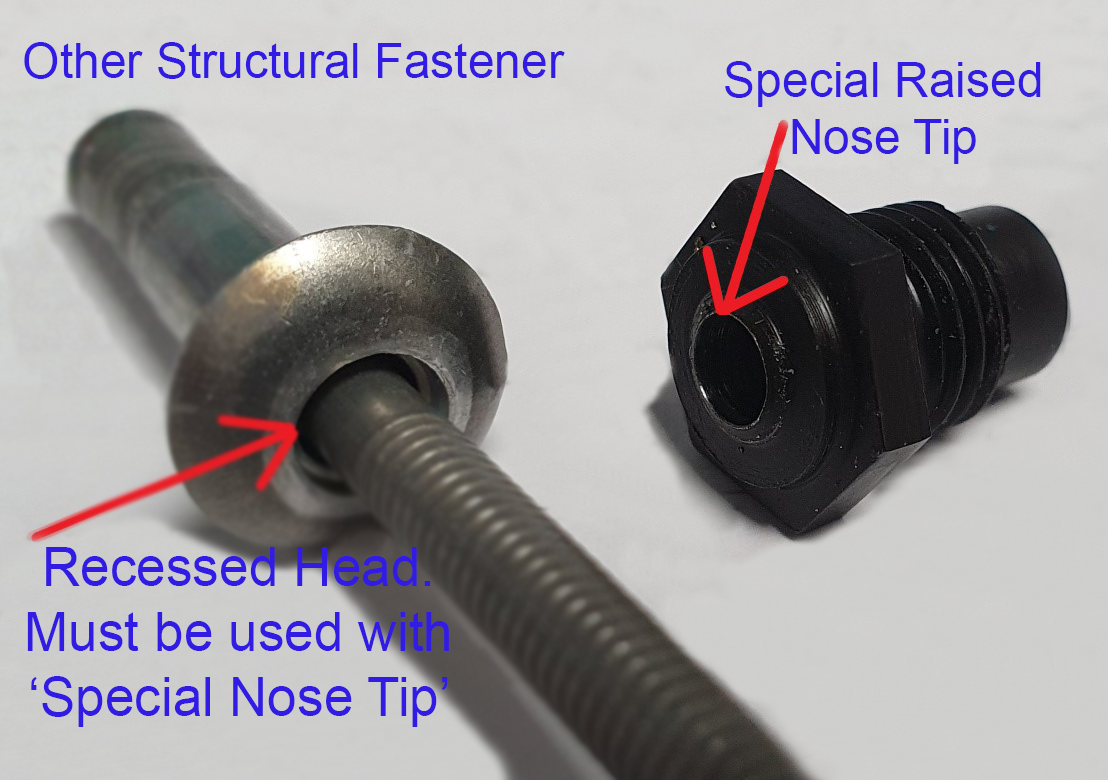

Huck structural blind fasteners such as HuckLok® and Magna-Lok® offer a distinct advantage over our competitors and copy products. They retain their mandrel after installation. The retention is made possible by the interaction of the mandrel and mandrel sleeve during the installation process, creating a solid circular lock. Their ‘captive’ subcomponents eliminate the ‘rattle’ caused by other types of non-structural or copy fasteners, some of which rely solely on the presence of a special nose tip to be installed correctly.

The presence of the locked-in mandrel increases the structural Huck fasteners load-carrying ability and overall increased level of strength (high shear & tensile strengths available).

The presence of the locked-in mandrel increases the structural Huck fasteners load-carrying ability and overall increased level of strength (high shear & tensile strengths available).

The ‘locking’ mechanism built internally into each fastener can be installed with any tool strong enough to pull it. Other products with similar profiles need special nose tips.

Many attributes make structural blind fasteners an ideal fastening solution. The Huck blind fastener range also includes Magna-Bulb®, Auto-Bulb®, PentaLok, FloorTight® and BOM®. These fasteners are available in a variety of materials, diameters, head styles, coatings, and structural strengths. They join material through either hole-fill or surface bearing. Hole-filling blind fasteners ensure holes remain correctly aligned after installation, preventing “sheet creep,” while surface bearing blind fasteners may be used with thin or brittle material, or where high tear-out loads are required.

Installed structural blind fasteners remain tight up to their minimum mechanical values, creating vibration-resistant joints that are less susceptible to failing. These versatile fasteners can also be used in conjunction with adhesives to ensure that a joint remains tight until the adhesives cures while also contributing additional supportive strength to the joint.

Finally, the installed cost of structural blind fasteners tends to be lower than that of other joining options, with savings on time, labour, and complicated inspection processes resulting in overall savings and higher output.

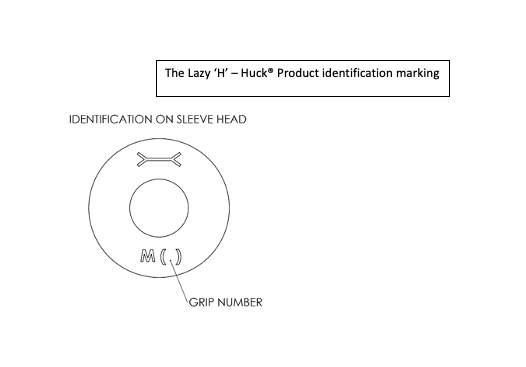

But how do you ensure that it’s a genuine Huck fastener? Huck fasteners have a lazy ‘H’ head marking. The head marking ensures that Huck fasteners are easily identified both during the installation process and once installed.

But how do you ensure that it’s a genuine Huck fastener? Huck fasteners have a lazy ‘H’ head marking. The head marking ensures that Huck fasteners are easily identified both during the installation process and once installed.

Star Fasteners in-house tool repair, service and hire

Star Fasteners’ accredited Huck tool repair and service department offers expert technical knowledge. We have a dedicated team of experienced engineers, fully trained to the relevant manufacturers’ recommendations. Star Fasteners has developed a reputation for providing a personal and reliable service, incorporating nationwide collection and return.

Every production environment, workshop and tool benefits from a regular maintenance program and Star Fasteners can help out with that too. We have a large selection of short or long-term hire tools to ensure that production isn’t held up. Advising customers on simple maintenance procedures to help prolong the production life of tooling systems are all part of the service.

We recognise that choosing a fastener installation tool can be fairly complicated; our service includes demonstrating the latest models and advising on tooling options best suited to both the application and the environment. Star Fasteners offer a wide selection of installation tools including the Makita designed Huck Range Force™ battery powered tool which has an electronically adjustable pull force and long stroke to enable installation of structural and non-structural rivets, and up to ¼ inch two piece HuckBolt® fasteners.

The Huck line of pneudraulic tools, such as the Huck 2025LB, 254 and 256 have been designed for use in production applications and repair work, they can effectively pull fasteners ranging from 3/16 inch blind rivets to 3/8 inchHuckBolts.

Huck Powerigs offer advanced design and quality manufacturing to deliver both best-in-class performance and long product life. Whether for mobile or factory use, there is a Huck Powerig hydraulic power source for the job, from portable electric, gasoline and diesel units to larger rigs that operate up to three individual tools.

Specialists in the supply and distribution of Huck Fasteners, Star Fasteners are proud to be the UK’s largest Huck stockists. Working globally with a diverse range of end users and distributors from across a number of industries, offering technical application knowledge and customer support.

www.starfasteners.co.uk

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.