WEVO-CHEMIE GmbH has developed a portfolio of silicone-based materials for battery modules and packs that serve as strong thermal, mechanical and electrical barriers, specially designed for electric vehicle industry.

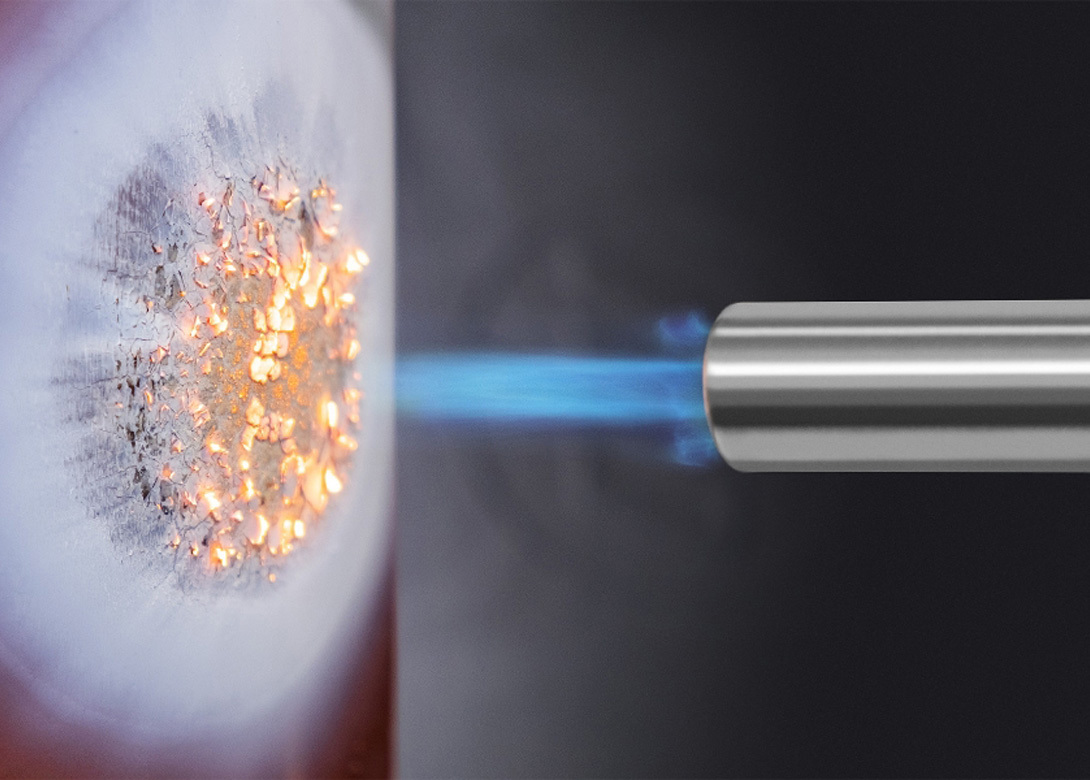

One of the most important requirements for batteries in electric vehicles is the ability to mitigate thermal runaway and protect against overheating. In addition to high heat and flame resistance, WEVO says its new formulation also offers further advantages, such as the reduced total weight compared with mineral or metal filled compounds and the avoidance of outgassing in the production process compared with foams.

Although thermal runaway of individual battery cells is rare, once it is set in motion it poses enormous threats, especially in vehicles and storage technologies for private households. This is because the typical failure mode involves violent exothermic decomposition reactions that generate so much heat that it can no longer be dissipated by the thermal management solution of the battery module containing the defective cell. If this effect propagates to other cells, the result could be a fire or even an explosion at the level of the module or pack. Since thermal runaway of individual cells cannot be completely avoided, the goal is to mitigate hazards and contain the effects.

WEVO ensures its WEVOSIL 27001 FL silicone has been proven in field tests by WEVO customers to be a highly efficient mechanical and thermal barrier that can be applied both above and between cells, depending on the cell type. The material achieves very high heat and flame resistance without any mineral or metallic fillers having to be incorporated. This has helped to keep its specific gravity low, thus also contributing to a lightweight battery design. Also, its electrical insulation properties helps prevent a short circuit in the module’s cell contacting system when applied to critical locations and circuits.

WEVOSIL 27001 FL, the company says, is more flexible than mineral solutions and stronger than foamed materials. In addition, it has a very low volatile content because only polymers which have been thoroughly degassed during a separate step of their manufacturing process are used in its formulation. Also, different flow requirements can be met with the lower viscosity WEVOSIL 22027 FL variant.

The thermally conductive gap fillers in the WEVOSIL 260XX FL series, specially designed to mitigate the propagation of thermal runaway, also include grades of extra-low density and weight, all of them certified according to the UL 94 V-0 flammability rating. At the same time, high dimensional stability is ensured and there are no curing by-products, which enables room temperature curing.

Ultimately, WEVO states that “if these tailor-made solutions are implemented in an early development phase, the overall safety of battery modules can be significantly improved by optimising thermal management for specific applications, and customising the configuration of thermal, mechanical and electrical barriers”.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.