Recently, Lohmann has launched its new high-tech adhesive tape portfolio which offers low-emission and low-odour products for bonding in vehicle interiors. All the products in this range are also produced in an energy-efficient manner.

The double-sided pressure-sensitive tapes of the new DuploCOLL® LE (Low Emission) 59xxx range are manufactured in water. This energy-saving manufacturing process also uses the 100% solvent-free TwinMelt® technology based on UV acrylates to enable enhanced adhesive performance. From this method, the DuploCOLL® range meets the requirements of OEMs for low VOC, fogging and odour values for materials and components in accordance with VDA 278.

The broad portfolio includes a selection of transfer, paper, scrim, film and foam tapes in various thicknesses between 0.03mm – 0.8mm. The tapes in the DuploCOLL® LE range can also be laminated with a wide range of damping materials, including felts, foams, textiles or knitted spacer fabrics, as well as customised materials, for use as a single-sided adhesive NVH (noise, vibration, harshness) solution.

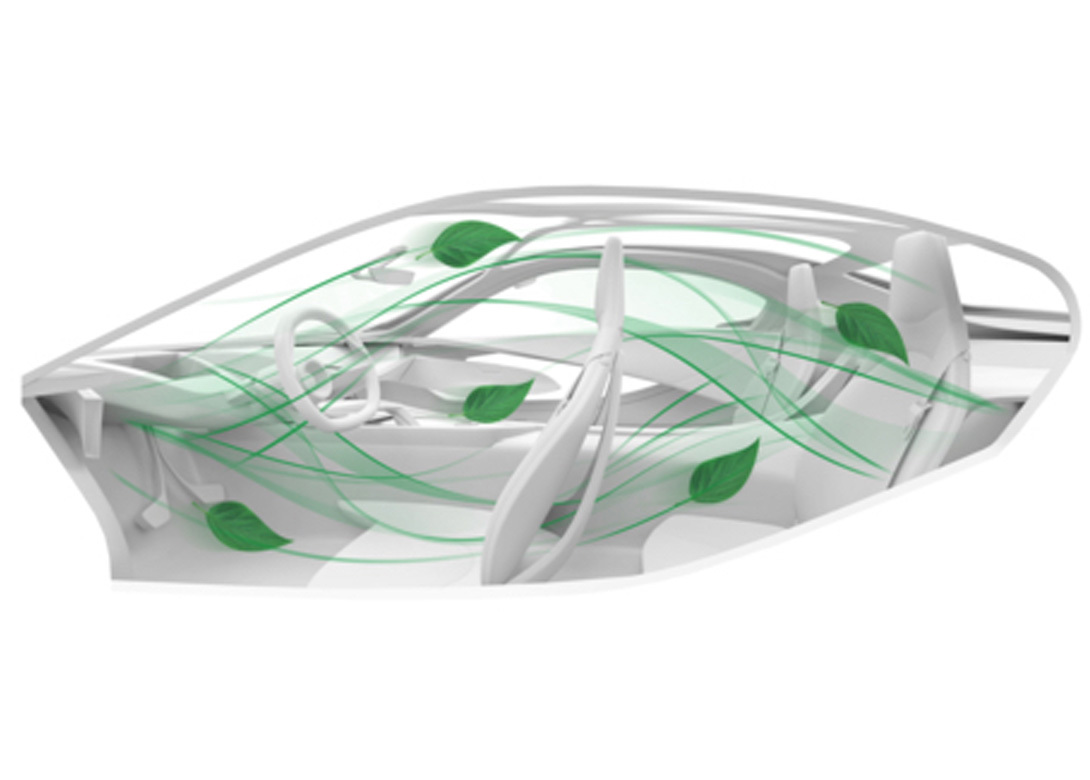

Lohmann ensures that even high-volume use of the adhesive tapes, such as bonding rear seat covers, pillar or door trims, do not adversely affect the air quality in the vehicle interior. With the DuploCOLL® LE product portfolio, a wide variety of designs can be realised. Different materials, such as plastic or wood decor, can be reliably fixed, even on low-energy material surfaces, thanks to high initial adhesion and reliable adhesive strength. In addition to full surface bonding, an adhesive stripe coating can be applied and, thanks to its special geometry, ensures that air can circulate and the seat is optimally ventilated.

The portfolio demonstrates good performance levels, even at elevated temperatures, as has been validated by tests. Also, the new adhesive range can be used to reliably bond sensor systems such as Hands-Off Detection (HOD) or Driver Presence Detection (DPD).

In an attempt to strive towards a more sustainable value chain, Lohmann GmbH produces a lower carbon footprint through the reduced energy consumption in the production process of DuploCOLL® LE. In addition, there is a high level of supply security its customers, as no gas is used as an energy source in the production of the tapes.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.