Here Cesare Certini, owner of CERMAC Srl – an Italian testing machine maunfacturer – discusses how a great deal of the structural and dimensional calculations of parts intended for mechanics and constructions are based on tensile testing, with fasteners being no exception.

Generally, a tensile test is performed on specimens obtained from machined parts, but in some cases this type of test can be performed directly on the finished piece. Both options could be applied to fasteners, depending on the part to be tested.

In the case of the EN ISO 898-1 standard, relating to bolts, screws and studs with specified property classes, there are two categories: FF – in turn divided into four categories, FF1, FF2, FF3 and FF4 – and MP – including MP1 and MP2. FF is the category provided for the testing of finished fasteners, while MP is the category provided for testing the material properties of fasteners and/or for process development.

In the case of the EN ISO 898-1 standard, relating to bolts, screws and studs with specified property classes, there are two categories: FF – in turn divided into four categories, FF1, FF2, FF3 and FF4 – and MP – including MP1 and MP2. FF is the category provided for the testing of finished fasteners, while MP is the category provided for testing the material properties of fasteners and/or for process development.

The subdivision into categories is due to the fact that sometimes the dimensions and the shape of fasteners do not allow the execution of tensile tests in the standard mode. The norm therefore states that tensile tests can be performed by obtaining specimens by mechanical machining or by carrying out the test directly on the fastener.

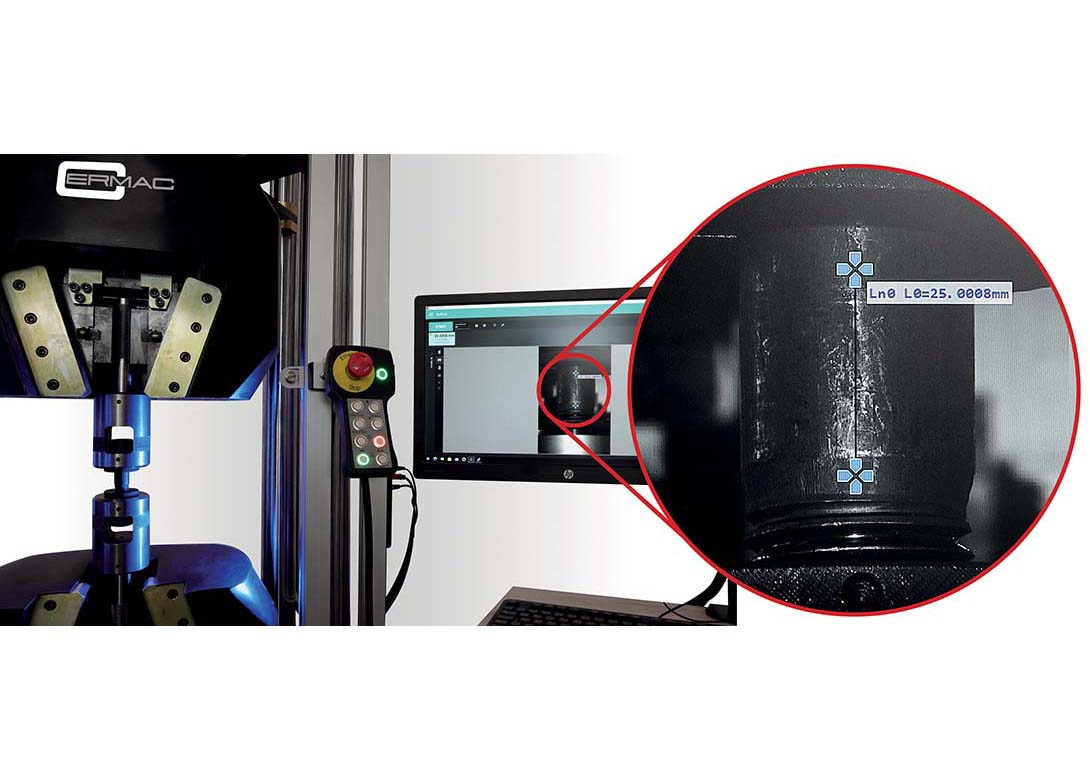

To be able to carry out the test directly on the screw, in the case of screws with important dimensions, it is however necessary to have a tensile test machine capable of exerting a considerable force such as the 1,000kN UTM by CERMAC Srl – capable of breaking screws or bars threaded in M32 in 10.9 – without machining the part.

This machine can also be equipped with an optical strain gauge to be able to calculate the yield strength even on fully threaded screws and threaded bars. This is a value that the standard does not require precisely due to the impossibility of calculating it with standard contact strain gauges. To perform the other tests required by EN ISO 898-1 it is also necessary to have a series of clamp devices with characteristics defined by the standard, such as minimum hardness of 45HRC, hole diameter, thread tolerance class, etc.

Among these accessories are those intended for the test with wedge support, which in addition to the special clamps, also require a wedge with angle, dimensions, and threads, depending on the screw to be tested.

In addition to testing machines, Cermac, thanks to its specialised workshop, is capable of making all these accessories tailored even for testing machines not of its own production, ensuring compliance with the standard.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.