An average automobile comprises of approximately 2,000 – 3,000 different types of screws. For the most stressed structural nodes operators can use high-stressed screws (HSS) that offer compactness and strength.

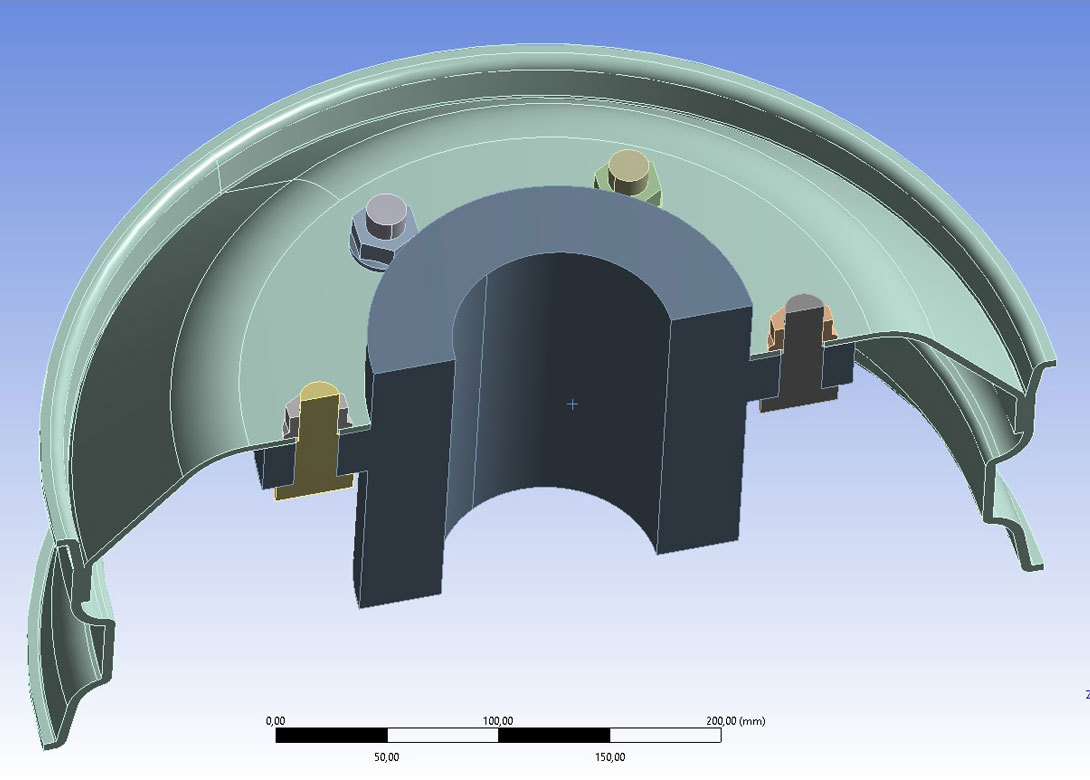

Ferodom s.r.o points out that a typical automotive application for high-stressed screws is the bolted joints that are used to fasten wheels (pictured below).

Characteristic features of common wheel bolts and nuts are the shaped contact surfaces, especially spherical or conical, which increase the friction and prevent self-loosening. Such a solution is appropriate for most of the cases and when they are properly installed, the drivers do not have to be worried that any of the car wheels will come loose.

In practice, however, there are cases when the wheels of cars become a critical design node. This is especially the case for overloaded vehicles or when wheels are replaced unprofessionally rather than by using controlled tightening – such as at the side of the road when there is a puncture.

Depending on the intensity of the overload, the bolts will be deformed and when the alternating loading continues, the fatigue fracture and/or the nut unscrewing will occur.

Uncontrolled tightening is a high safety risk. So it is recommended that after replacing a wheel, it is checked by an authorised service within 50km - 100km. However, drivers that ignore this advice can cause potential crashes. This is the main initiator for the development of non-standard methods of bolting locking.

There are several such methods on the market today, including the proven TaTrim lock point application from Ferodom. Its advantages are reliable locking independently of friction coefficient and degree of tightening, simple application and low price. Unlike known check points, the TaTrim protects nuts and/or bolts from spontaneous rotation too.

The National Transportation Safety Board reports that there are approximately 1,000 truck accidents due to loose wheels annually. In the UK, according to the UK Department of Transport 2006, it is 400 cases per year, of which an average of 7 cases ends tragically. Is it a lot or not? In any case, not enough attention is paid to this topic.

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.