By Paolo Cattaneo, managing director, Growermetal Srl

Growermetal, based in Calco, northern Italy, introduced the Grower TenKeep® safety washer to the market in 2019 – receiving a very positive response with the product even winning a Route to Fastener Innovation Competition award at Fastener Fair Stuttgart.

Specially designed to ensure maximum performance against unscrewing of bolted joints – even in the presence of extreme vibrations and dynamic loads – the Grower Tenkeep® washer is a result of a Growermetal R&D project where more than 400 types of geometry were tested before defining the final shapes of the two different sides of the washer.

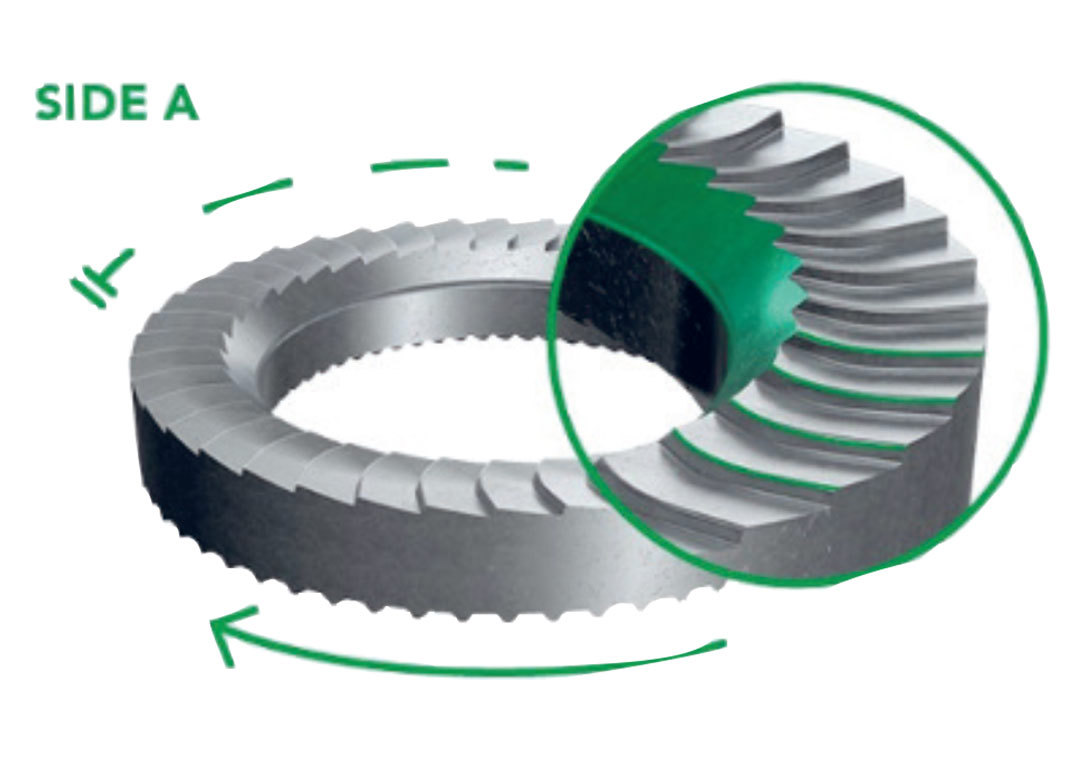

‘Side A’ of the washer, used on the head of the screw/nut, slides against the surface of the underhead of the screw/nut when tightening the bolted joint. The advanced serration geometry of this side instead counteracts very efficiently the loosening of the bolted joint connection. The hole on ‘Side A’ has a chamfer, which provides the dual function of avoiding any interference with the radius under the screw head, and allows the user to orientate the washer correctly. Due to the peculiar geometry of the serration, ‘Side A’ is also known as the ‘boomerang side’.

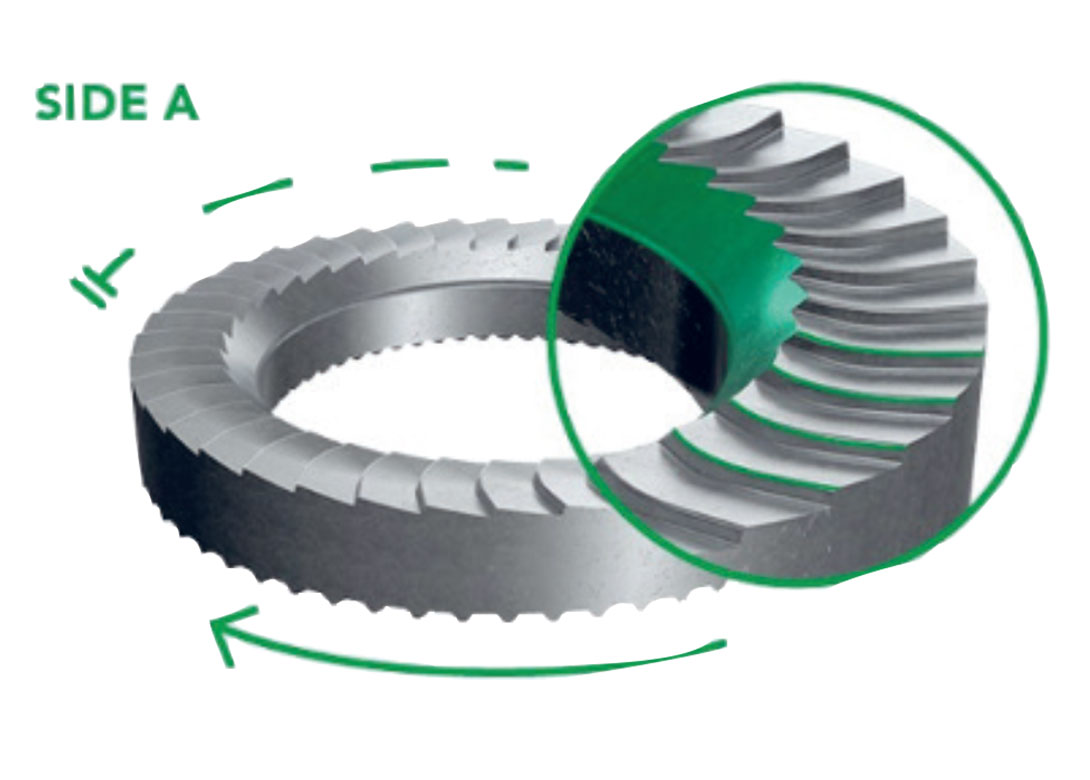

‘Side B’ of the washer, which is in contact with the bearing surface, becomes immediately solid with the material when the bolted joint is tightened. This is thanks to the exceptional grip of its knurling. The washer then remains permanently solid to the bearing surface.

Using the Grower TenKeep washer, the friction conditions in the bolted joint connection are defined and uniform. They do not depend on the material or on the mechanical features of the bearing surface. As a consequence, the tightening torque to be applied in order to achieve the desired screw preload is always the same, up to 12.9 bolt class.

In order to resist the most demanding application environments, the Grower TenKeep washers are supplied with zinc flake coating – Delta Protekt® KL120, which is a high performing product of Dörken MKS® and guarantees a corrosion resistance performance of at least 1,000 hours.

Continuous testing

Whilst the Grower TenKeep has established itself within the market, Growermetal is continuing to carry out test studies on the safety washer in order to demonstrate, in practice, its performance and specific features.

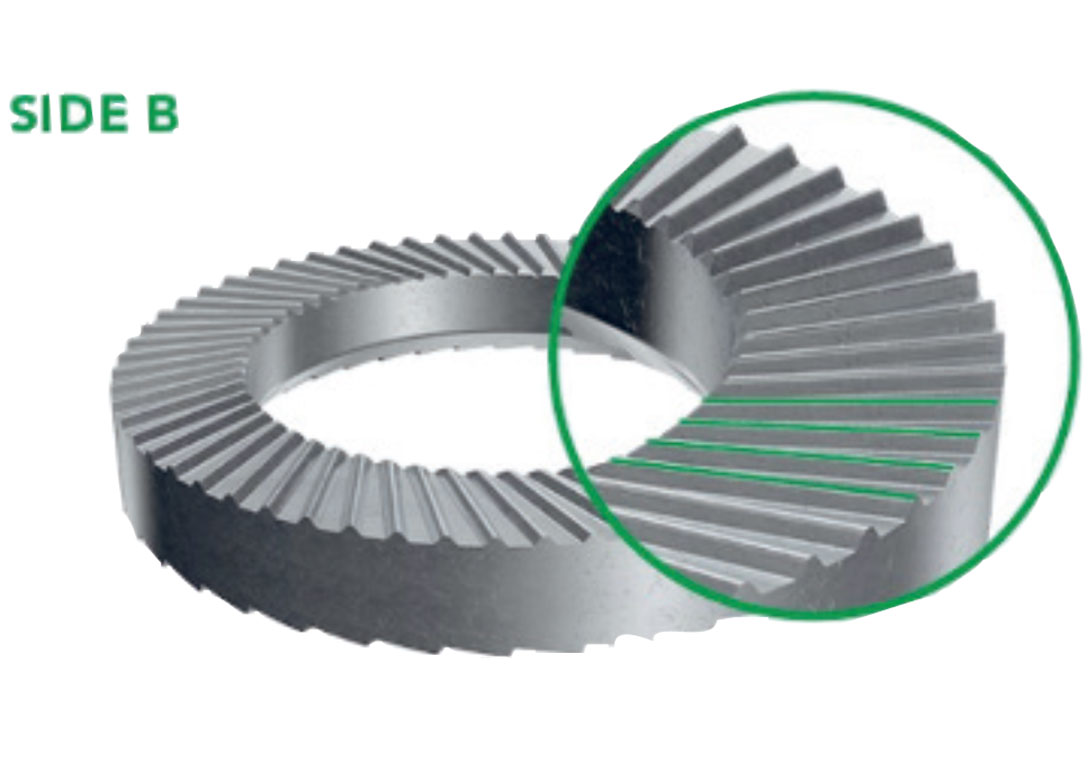

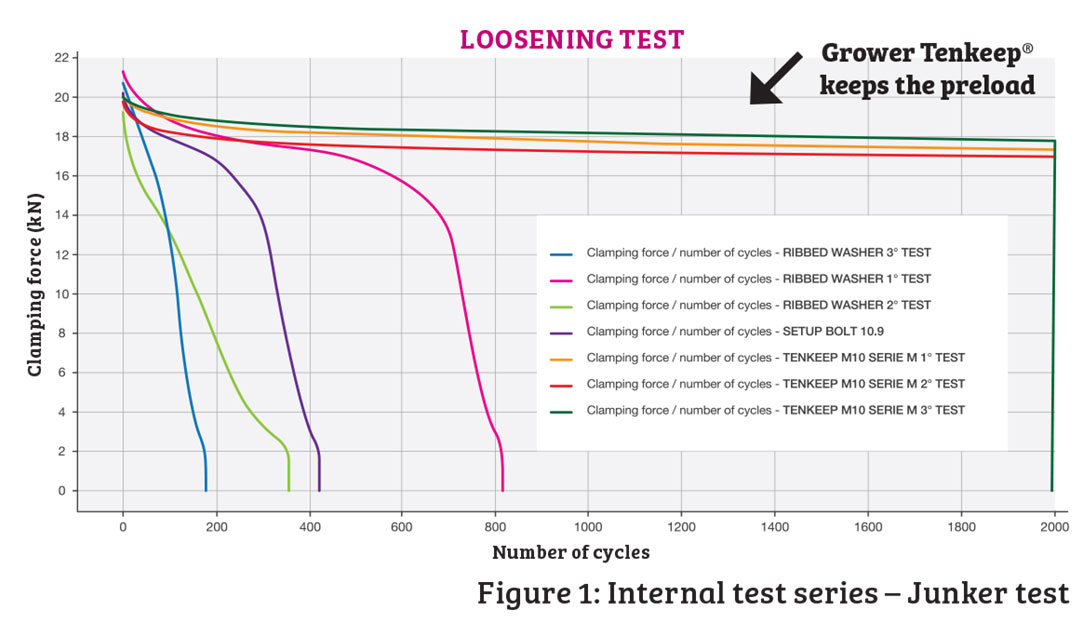

Firstly, a large number of internal tests have been carried out at Growermetal’s laboratory. The test series included the most important vibration test, Junker test, which is executed in accordance with standards DIN 65151 and DIN 25201-4. During this challenging vibration test, which provides the run of 2,000 cycles in each single session, the Grower TenKeep safety washer kept the preload of the bolt assembly in a highly reliable manner, even in direct comparison to other ribbed washers (Figure 1).

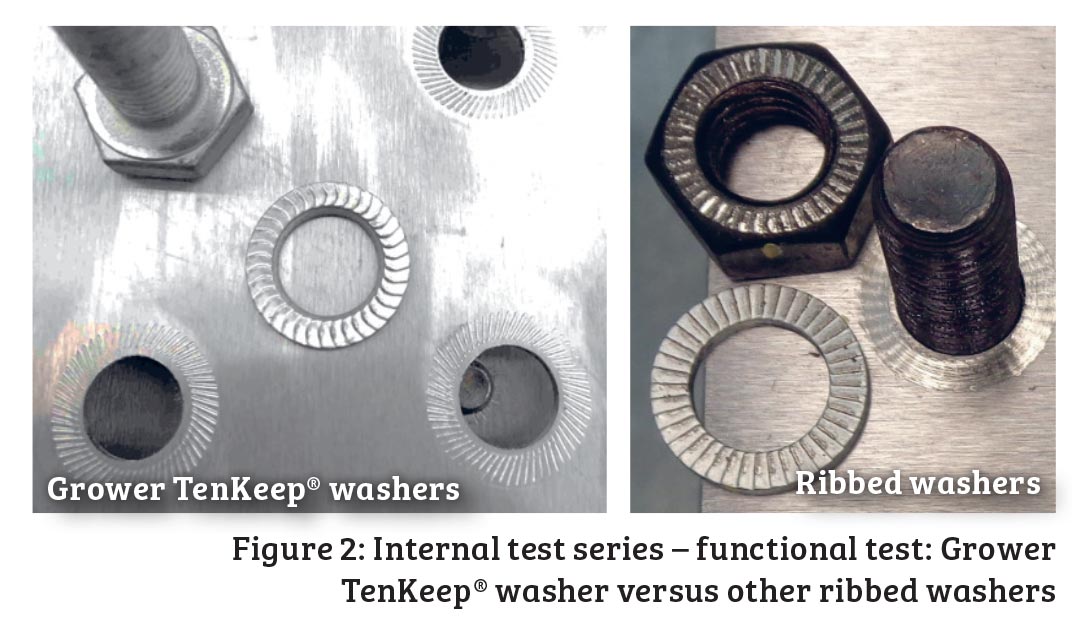

In addition to the vibration tests, Growermetal carried out a series of internal functional tests. The tests compared the performance of the Grower TenKeep with other types of ribbed washers and the result showed (Figure 2) that during tightening and untightening the Grower TenKeep washer does not slip, since its serrations indent the 200 HV steel bearing surface without damaging it.

Dörken corrosion testing

As a result of the fruitful cooperation between Growermetal and Dörken MKS, further external performance tests were carried out by Dörken. The relating test results were officially presented on 28th November 2019 during the annual Dörken Days event in Frankfurt, Germany, in order to discuss the current trends and challenges in the field of corrosion protection.

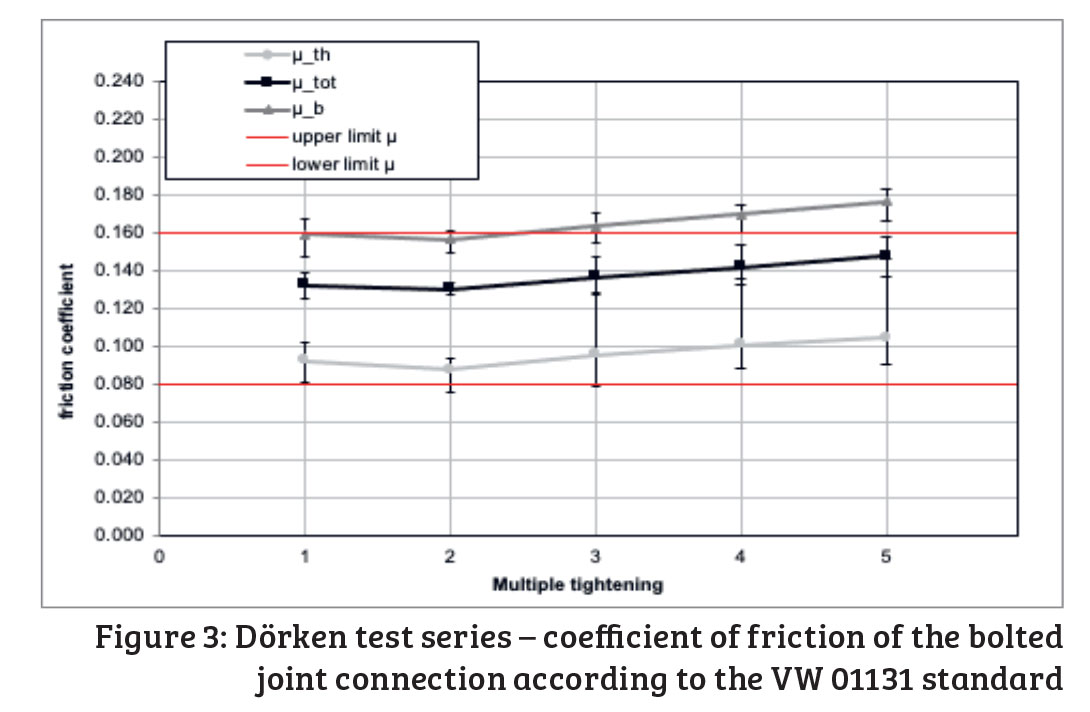

Dörken MKS took into consideration in its tech centre several factors that play a decisive role in a technical fastening assembly. In the first test series the technicians of Dörken MKS tested the coefficient of friction of the bolted joint connection according to the VW 01131 standard, using the M10 Grower TenKeep (large series) together with a M10 x 65 10.9 flanged bolt on bearing surfaces of aluminium and KTL. In Figure 3 the washers were serrated on a KTL coated surface. The values of μ_th (thread) and the μ_tot (total) are inside the provided range. Even if the value μ_b (bearing) results being over the tolerance limit, the performance is considered compliant as the VW specification allows higher COF values with locking serration parts. Furthermore, no stick-slip effects occurred.

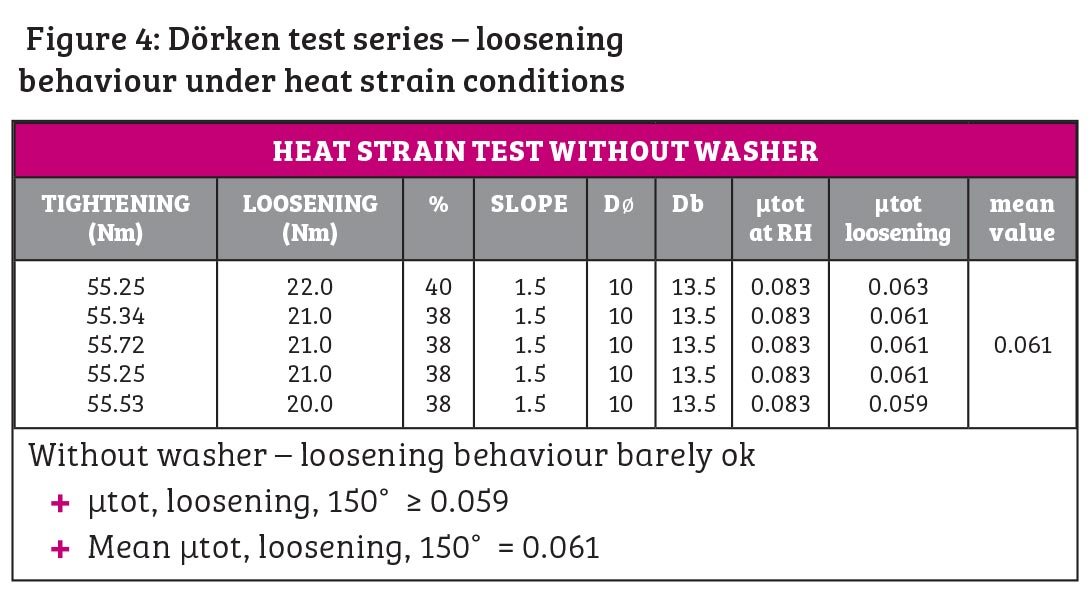

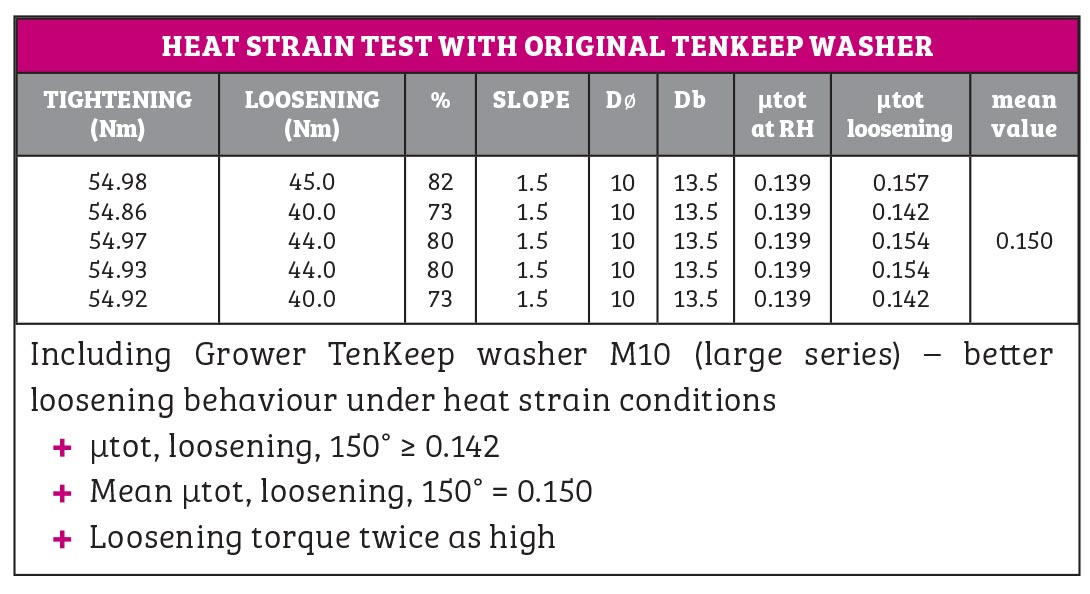

In the second test series, the loosening behaviour under heat strain conditions was evaluated by following the guidelines of the standard VW 01131 (Figure 4). In this case, a comparison was made between a M10 x 65 10.9 bolt without a washer and a bolt with a M10 Grower TenKeep washer (large series) on a test plate in HL 220HV steel.

With the Grower TenKeep washer the test performed extremely well, since the coefficient of friction was much higher and the loosening torque was almost double (44Nm – 45Nm) compared to the one applied on the bolt without a washer (21Nm – 22Nm).

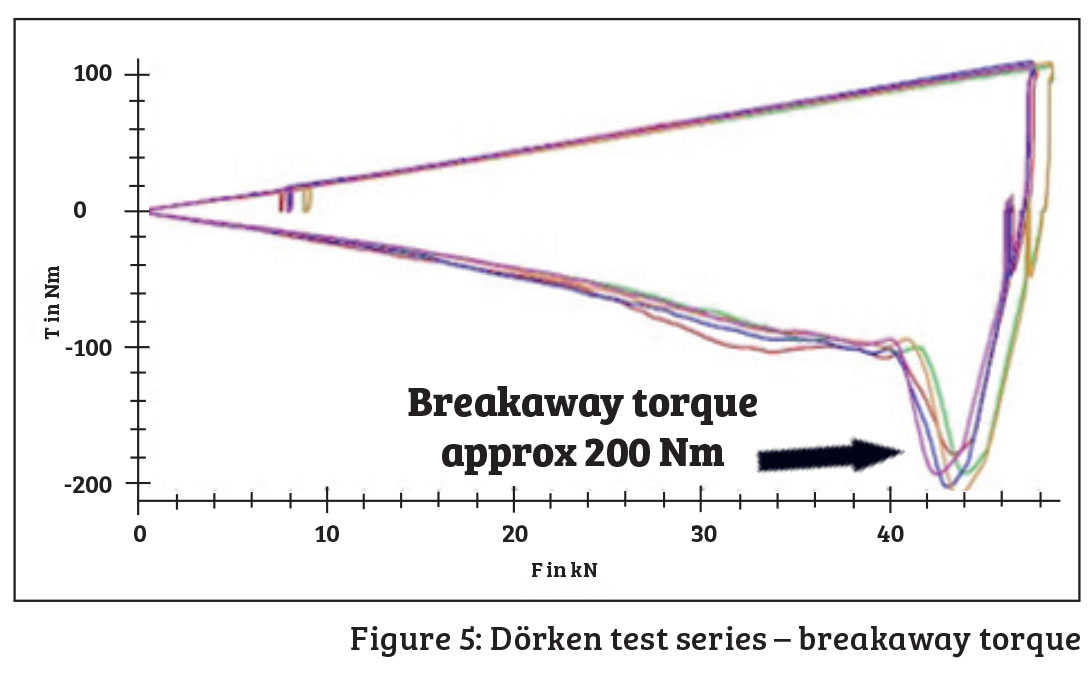

In the third test series, a M10 bolt was fastened on an aluminium surface by applying a tightening torque of 55Nm and rotating by a further 90 degrees up to 100Nm, as described in the standard VW 01126 (Figure 5). The breakaway torque was twice as high, approximately 200Nm.

The visible ‘nose’ in the graph during the untightening shows the extra torque needed to win the resistance of the Grower TenKeep washer’s ‘boomerang side’ (Side A) against the bolt loosening.

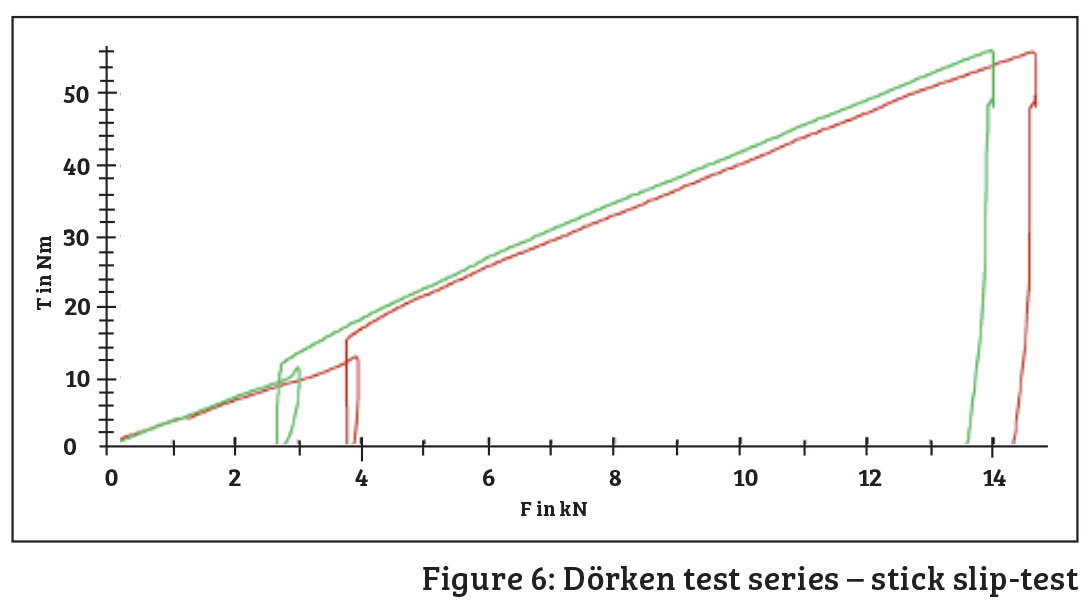

In the fourth test, and last series, the stick-slip effect was examined (Figure 6). Doerken technicians studied the behaviour of Grower TenKeep washers under regular assembly conditions (200/20rpm) and no stick-slip effects occurred.

In conclusion, the numerous tests confirmed that Grower TenKeep safety washers keep the preload in presence of vibrations and show a very good performance on different types of bearing surfaces (e.g aluminium, KTL and steel <300 HV) without any slipping on the bearing surface. The breakaway torque is at a high-level. Even under heat strain conditions, the washers show a good loosening behaviour and no stick-slip effects occur. Furthermore, the washers are reusable several times without loss in performance.

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.