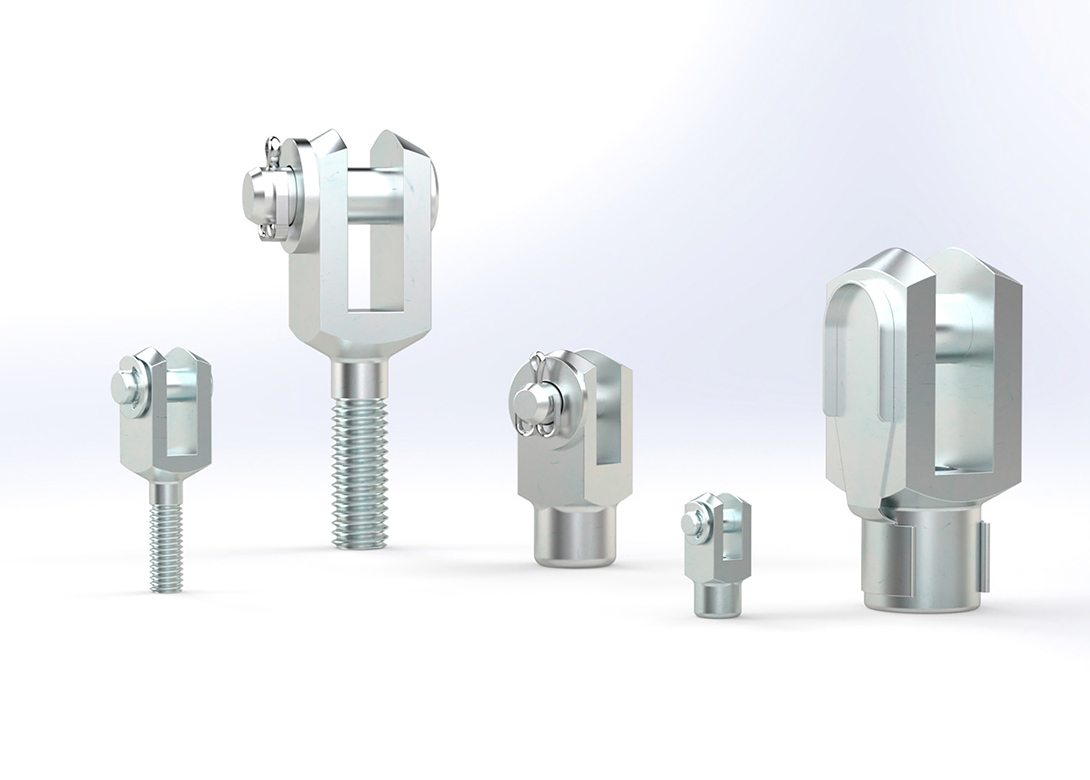

Available in a wide variety of sizes and options, the new clevis fastener kit from WDS Components Ltd contains all parts required to complete a secure fastening for faster and simpler selection.

Widely used in machinery automation and automotive manufacturing, clevis fasteners form pin joints with a wide range of uses from attaching machine shock absorbers to rod ends for gas struts. The clevis fastener comprises a clevis fork, clevis pin, a washer and a pin or clip used to secure the joint. WDS now supplies these components combined in an easy to order kit, removing the need for the customer to specify and select individual components.

Enabling faster design, the kits have a single part number and CAD file for download and import. Negating the need for four or more separate files when ordering clevis kit components separately, this makes design a much faster process. CAD files in a wide range of formats can be downloaded free of charge from wdscomponents.com.

The kit format also ensures compatibility according to fitting type required and size, saving time in ordering and speeding up manufacturing operations. As with all components from WDS, experienced customer service and technical support teams are available via phone and e-mail to assist with any design specification questions engineers or procurement teams may have.

The kits are available in robust zinc plated steel (part number WDS 551) or, for hygienic applications or where the highest resistance to corrosion is required, 304 stainless steel (part number WDS 851). Both kits are available with male and female fittings and a wide range of 43 sizes, from thread M4 to M12.

The kits also have a range of fasteners to give choice depending on security of closure combined with ease and speed of fitting. The cotter pin provides the highest security of fastening while the spring clip affords the greatest ease of installation; the E clip is a balance between the two designs.

To ensure compatibility with both new and existing applications, the components have DIN numbers meaning that they conform to a metric standard. The clevis forks meet DIN 71752 and the other components also carry a DIN number where required.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.