One of the biggest challenges manufacturers face when assembling metal parts is achieving a secure joint while maintaining cost efficiency and production speed. POWERLOK® II™ screws from CELO offer a reliable solution for assembling components subjected to high-levels of vibration.

POWERLOK® II™ TRILOBULAR® screws: secure metal assembly without extra locking elements

In many applications, extra locking elements – such as locking patches, adhesive patches, or washers – are used to prevent loosening. However, these solutions add complexity and cost to the assembly process. But what about other challenges, such as temperature fluctuations? How can you ensure a secure joint under high operating temperatures?

Eliminate screw loosening with POWERLOK® II™ screw – the proven locking technology

POWERLOK® II™ screws are a proven solution for assembling components exposed to severe vibration conditions and expansion/contraction cycles in all-metal tapped holes. Their unique design provides a reliable locking function regardless of the fastened material or operating temperature.

With excellent resistance to vibration-induced loosening, POWERLOK® II™ eliminates the need for additional locking elements and complies with IFI 524 regulations for screw loosening resistance. The screws can reach Class 10.9 mechanical properties, offering high strength properties suitable for a wide range of demanding applications.

How does POWERLOK® II™ screw work?

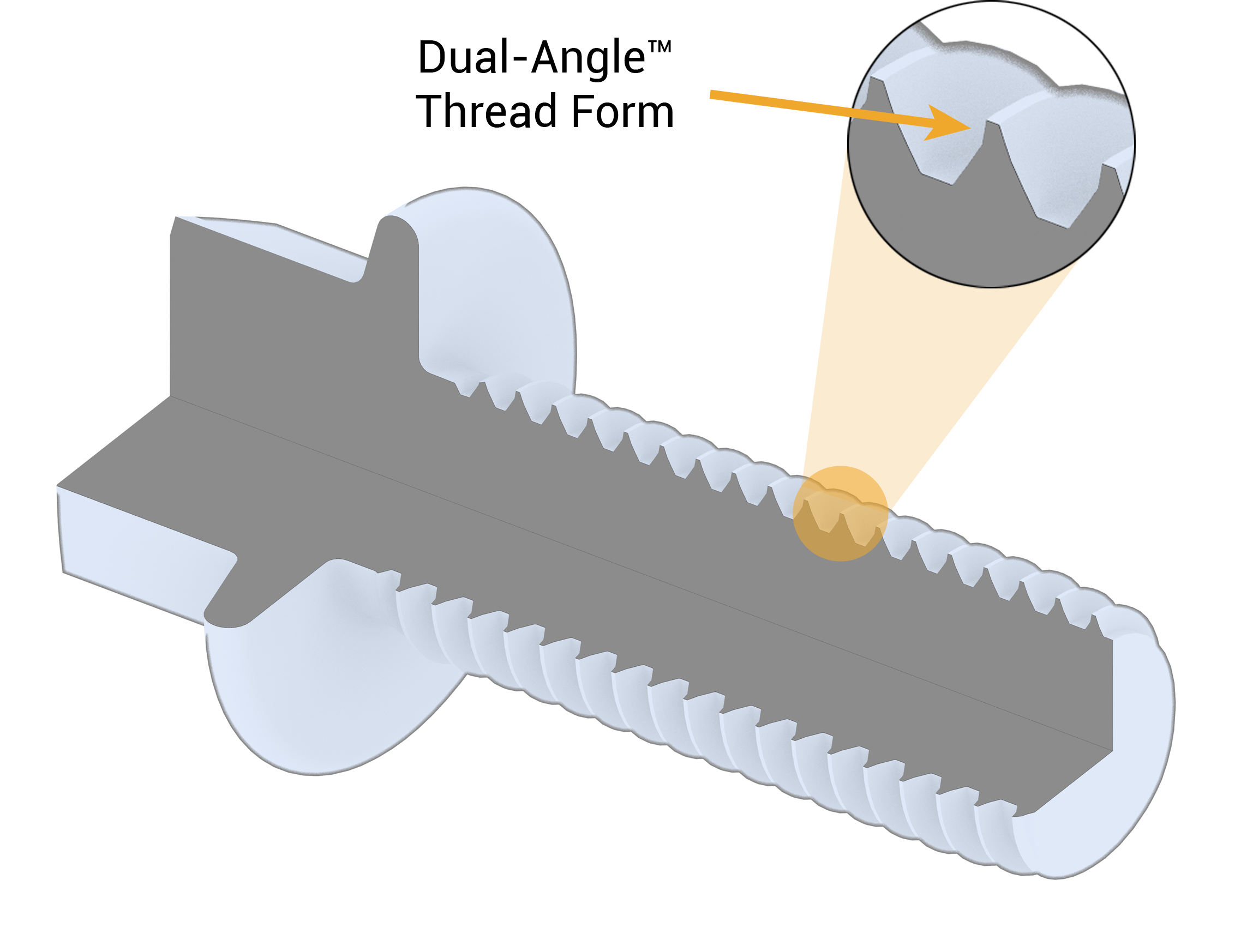

POWERLOK® II™ screws achieve enhanced locking action through the combination of a Dual Angle™

POWERLOK® II™ screws achieve enhanced locking action through the combination of a Dual Angle™

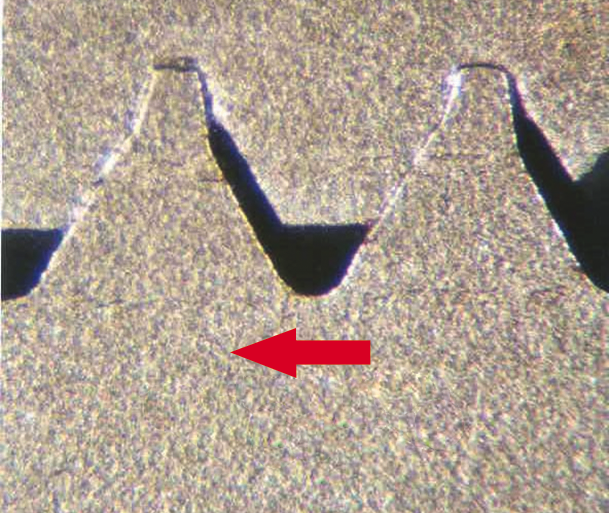

thread form and a TRILOBULAR® thread body section. The innovative Dual-Angle™ thread form combines a 30° thread overlapping with a standard 60° thread. This design interferes with the root of the nut thread, eliminating tolerance gaps. The centralisation of the POWERLOK® II™ screw lobes in the nut member allows the crest on the fastener thread to flex elastically under clamp load, simulating the live action of a spring washer along the entire screw length.

Key benefits of POWERLOK® II™ screws

Which applications are suitable for POWERLOK® II™ screws?

POWERLOK® II™ screws are widely used in metal pre-tapped holes, particularly in automotive and other high-volume assembly applications. They provide an ideal solution for situations requiring high vibration resistance and consistent performance, even after repeated assembly and disassembly.

Custom POWERLOK® II™ screws – precision solutions for every assembly

CELO customises POWERLOK® II™ screws to fit specific installation requirements. These screws can be configured with various recess types, thread points, coatings and cleanliness levels – all based on customer specifications.

To enhance assembly efficiency, POWERLOK® II™ screws can also feature a specialised thread point design that prevents cross-threading during insertion. This makes them an ideal choice for semi-automatic and robotic assembly lines, ensuring a smooth installation. POWERLOK® II™ threads on double-end studs replace inconsistent locking nuts, enabling reliable fastening with standard nuts or Class 2B (6H) tapped holes.

Learn more about how POWERLOK® II™ screws can enhance your metal assembly process: https://www.celofasteners.com/en/2099-powerlok-ii-screws

Click here to buy directly from CELO's e-shop.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.