Products for conductive coatings and thermal interface materials, as well as assembly adhesives and liquid seals, are used to protect battery packs in electric cars. With its wide range of technologies and know-how, Henkel supplies a number of complete solutions for the automotive industry and especially for electric vehicles.

An important prerequisite for maintaining the service life of electric batteries is a permanently functioning seal for the battery housing in the car underbody. The battery housings installed in the car underbody are seamlessly sealed with the room temperature cross-linking two component polyurethane foams from the SONDERHOFF FERMAPOR K31 product family. They protect the electric batteries against moisture, corrosion, and dust. They also dampen vibrations and are resistant to temperature and chemicals on the polyurethane material specifics. Protection against these influencing factors helps to improve the long life of the E-batteries.

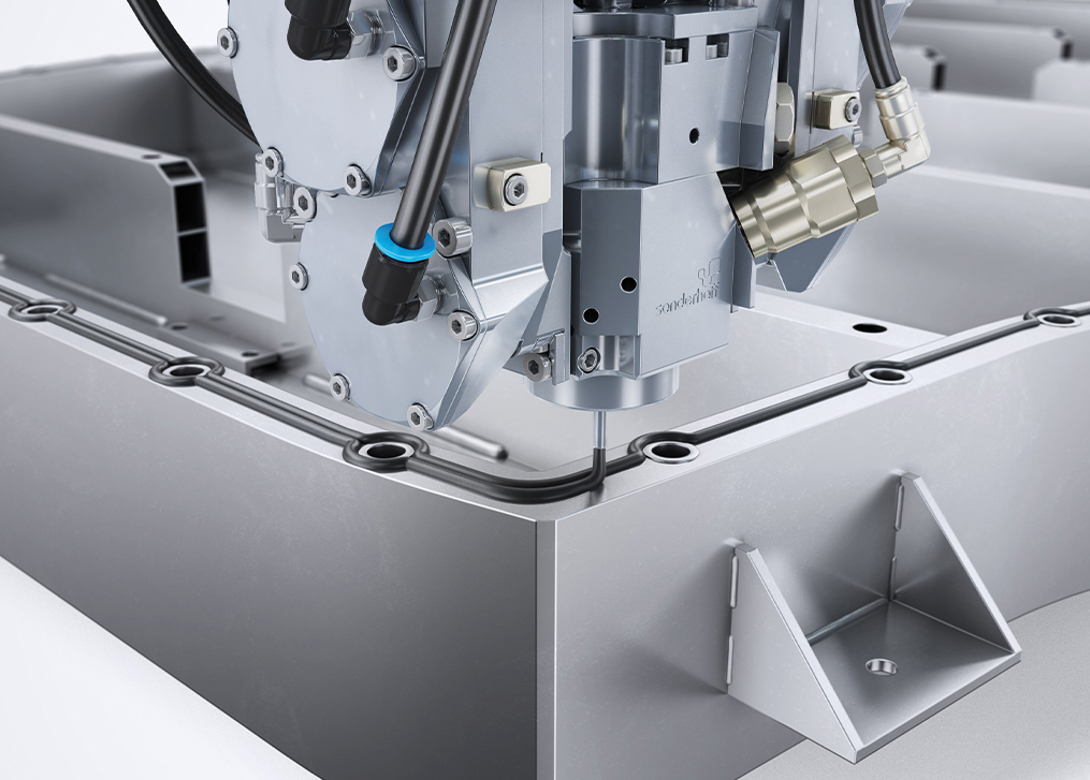

The die cast aluminium housings for holding the electric batteries are sealed efficiently, precisely, and securely using FIPFG (Formed-In-Place-Foam-Gasket) technology. The CNC-guided mixing head of the SONDERHOFF mixing and dosing machine moves along the housing geometry and applies the two component polyurethane sealing foam SONDERHOFF FERMAPOR K31 with precise contours. After foaming, a seamless foam gasket is produced which cures at room temperature.

The elastic foam cell structure of the seal is compressed when the battery housing cover is screwed tight. Thus, the housing and cover are sealed to each other. The excellent resetting ability of the foam sealing allows the housing to be opened and re-closed repeatedly for maintenance purposes. At the same time, the sealing effect of the housing seal is maintained by the consistently good compression of its foam structure. The housing is sealed, and the batteries are protected against splash water and weather influences.

With the SONDERHOFF SYSTEM SOLUTIONS, from material systems to mixing and dosing equipment to contract manufacturing, Henkel offers a ‘one stop solution’. Henkel's experts provide application technology advice from the design phase of the components through to fully automated material application using Formed-In-Place (Foam-Gasket) technology in series production. The tailor-made automotive solutions with products from the SONDERHOFF portfolio range from foam gaskets based on polyurethane or silicone and systems for bonding and potting to mixing and dosing machines for automated material application on industrial components. Alternatively, Henkel also takes over the sealing, bonding, or potting of components in contract manufacturing.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.