The year 1908 was one of the most historically significant years both for personal motorised transport and for industrial assembly. With the Model T, the Ford Motor Company launched an automobile on the market which could be manufactured for the first time in large numbers at an affordable price. This not only heralded the age of private transport for the masses, but this first assembly line also gave the green light to industrial series production in the automotive industry. Due to advancing rationalisation measures, amongst other things in the form of a comprehensive division of labour, production rose to the point where it was efficient enough to produce up to 9,000 vehicles a day.

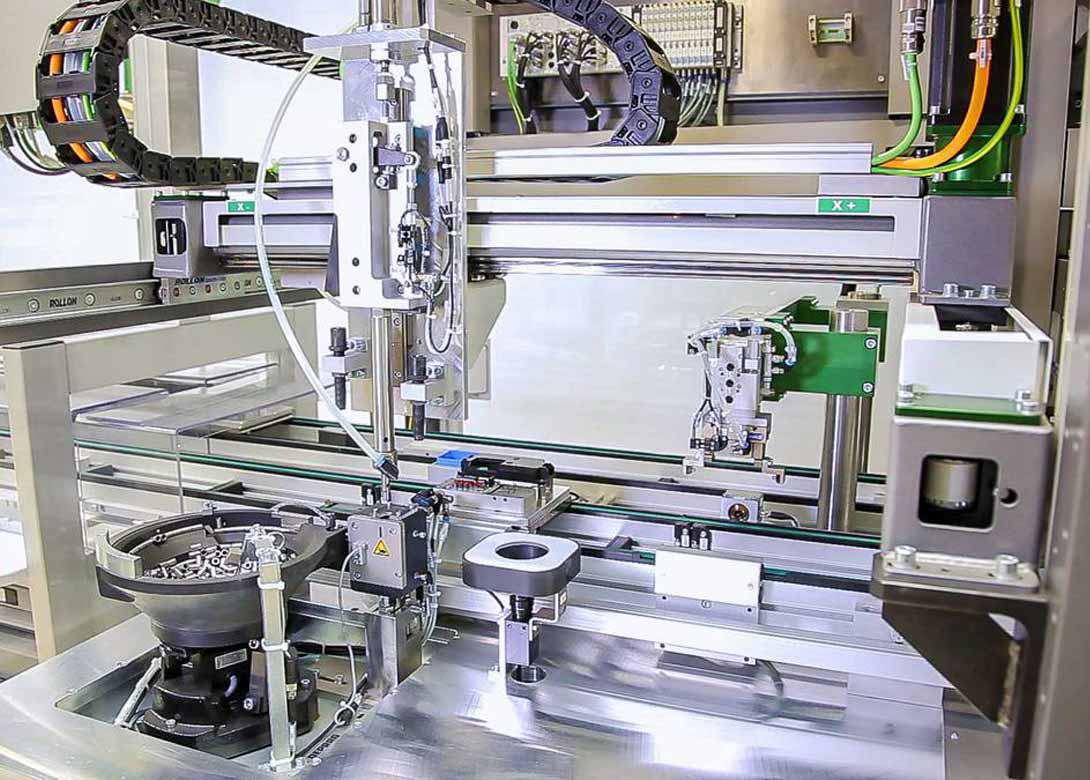

Since then, despite an enormous increase in output, the basic principle of manual assembly work has essentially remained the same. Product assembly has been revolutionarily influenced by an increase in automation and digitalisation. Today, fully automatic systems can be remotely operated thanks to intelligent, Industry 4.0 capable hardware and software components and are interconnected with correlating systems, linked by feeding technology. An assembly system component can be fed and positioned, whilst at the same time fasteners such as screws or nuts are sorted, correctly positioned, separated and fed directly into the screwdriving tool – and all in the blink of an eye. However, changes in relevance to current or future influencing factors or constantly developing requirements still relentlessly force the industry to come up with new enhancements.

One of the most relevant of these factors is the advancement of miniaturisation. Today, modern processors of just a few square millimetres are equipped with many billions of transistors. Most dirt particles appear huge in comparison to such small structures on the nanometer scale, and depending on the application, can pose a significant risk. For example, even the smallest conductive particles can cause a short circuit in electronic components. Material particles from carbon fibre reinforced plastics are conductive so the use of these new and more efficient materials actually heightens this risk. Therefore, the increased relevance of technical cleanliness goes hand in hand with miniaturisation.

DEPRAG SCHULZ GmbH from Amberg, Germany, specialises in the field of automated screwdriving and feeding technology. The recipe for long-term success is the continued drive for evolution and innovation, combined with the development of intelligent and efficient system solutions. With this in mind, DEPRAG Schulz GmbH developed its complete CleanFeed concept with specific CleanFeed components to meet the requirements for technical cleanliness in feeding. It includes elements for low abrasion part feeding to minimise the generation of damaging particles from the outset. Low abrasion sword feeders are particularly gentle at sorting, separating and suppling fasteners. Sensors on the device automatically determine the number of strokes necessary so that stroke movement and therefore abrasion is kept to a minimum. Furthermore, hoppers help to keep a consistently low quantity of fasteners in the feeding system because fewer screws mean less contamination.

However, because the generation of particles cannot be entirely eliminated, suction systems are also an effective method of creating cleanroom conditions. The DEPRAG “Particle Killer” targets and removes dirt particles before assembly and ejects them through a filter. The DEPRAG SFM-V vacuum screwdriving module on the other hand, uses suction to remove residual dirt directly from the screwdriving tool via additional vacuum sources. As well as modifications to the hardware, particle contamination is also combatted by intelligent adjustments managed by the controller, such as a reduction in speed during bit engagement with the screw head, at the same time averting wear and tear on the tool.

Efficiency has always been a vital aspect for the entire supply chain in economical assembly systems. The DEPRAG vibratory spiral feeder eacy feed provides a particularly effective drive concept. Both the controller and drive of this efficient feeder are based on a power supply of 24 V/DC. Using oscillating magnets in the feed bowl, this is sufficient to trigger periodic oscillating motions and attain an energy saving of around 80%. The use of a universal power supply unit allows worldwide application of the device without modifications. Furthermore, the intelligent PFC100 controller allows for customised settings without time-consuming mechanical intervention. If assembly should be automated to the highest degree possible, but quantities do not justify a fully automatic feeding system, then a screw presenter offers an inexpensive, compact and quickly implemented solution. Screw presenters can be modified for different screw sizes with just a few steps, they are gentle on components, can be utilised in handheld or stationary applications and are fully self-sufficient thanks to their integrated controller.

Today, the global market situation is more dynamic than ever. New products reach the market quicker and the capacitive future of products is not always predictable. A lack of empirical data and uncertainties are the norm in quantity planning for the E-mobility sector. These circumstances require the most flexible solutions possible with short reaction times as is the case in hybrid assembly systems with a combination of manual and automated processes. In this way production can be expanded as necessary through the implementation of intelligent manual work stations without sacrificing processing reliability. The operator is taken step by step through the assembly task. Sensor technology activates the correct parameters for each screw position, releases fasteners, notifies the operator of subsequent tasks and evaluates results.

The Pick-and-Place procedure guides the operator by picking up the correct fasteners and precisely directing them to the correct screw position. Assembly remains both flexible and reliable. One of the greatest challenges for hybrid assembly systems is the pairing of man and machine who do not always work at the same tempo. The solution is creating buffer zones, using intelligent linear conveyors. This enables larger distances to be bridged as well as controlling part flow. Depending on requirements, the conveyors provide part buffers or separate the part flow. Another measure in attaining highest flexibility is the use of modular system concepts with standardised components. DEPRAG has a comprehensive module portfolio including sensor-controlled screwdrivers, feeding systems, controllers etc., all from a single source. These individual modules are already coordinated with each other, thereby saving time and effort in integration. The high flexibility means that assembly systems can be quickly adapted to the current market situation; counteracting planning uncertainties and quickly reacting to changing requirements.

Henry Ford’s own intelligent and efficient ideas shaped his production so that it was as economical as possible. For ten years, his company produced only black body parts and obligated suppliers to deliver precisely dimensioned wooden shipping containers whose boards were then taken apart to be used in vehicle construction. Such measures may be unthinkable today, however the objective of realising efficient, intelligent system solutions still holds true. Assembly systems are complex, perfectly coordinated interdependent systems comprising of numerous components. A system malfunction in feeding technology can cause a delay to larger parts in the supply chain and thereby create far-reaching financial and organisational consequences. With its widely diversified component portfolio designed to satisfy any requirement, DEPRAG Schulz GmbH provides flexible and reliable options for the realisation of highly profitable assembly systems.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.