While automotive suppliers all over the world are facing an evolving array of issues and the challenges, Growermetal is able to support customers with a high variety of safety washers, and blanked parts, that provide the best solutions for customers looking for quality, flexibility and accuracy.

Over recent years the automotive industry has been called to face many challenges, from technical and environmental implications, to the consequences related to the Covid-19 pandemic outbreak, as well as the impact of the Ukraine crisis.

While the dynamic market is bringing a relevant change in business manufacturing, global companies like Growermetal are reacting with solid efficiency, technical know-how and a natural inclination to innovation – in order to confirm its good market position and establish once more its reliability for every customer and partner looking for the best fastening solutions.

The Italian company has always been highly specialised in the production of safety washers and blanked parts, shaping a new definition of safety since its origin in 1950. From that moment on, Growermetal has been run by the Cattaneo family, with the company inheriting the same vision of the founder Virginio Cattaneo – to provide an extended product portfolio suitable to a great variety of applications, with 100% Growermetal quality.

“Nowadays, after more than seventy years of corporate history and innovation goals, this purpose continues to be the business’ main strength, with its products used in a variety of different applications – supported by a delivery service and distribution that covers the European and global markets,” explains Paolo Cattaneo, CEO of Growermetal.”

Certified solutions and treatments

Within the automotive industry in particular the company has developed a great level of specialisation, reaching many important objectives by using its certified management system according to IATF 16949 – a technical requirement for the automotive sector that helped Growermetal align itself to the requests to develop and manufacture products for automotive applications.

Another key part of Growermetal’s capabilities is represented by its in-house treatments, with a modern plant where mechanical zinc plating is carried out. The main purpose of this coating is to provide an anticorrosive layer free from hydrogen embrittlement risks, with unparalleled performances in terms of quality and resistance. From this point of view, the search for the best solutions has led to the approval of the mechanical zinc plating process according to the automotive standard FCA PS.50042 – Edition 11/2015. Just another development that help set the company apart as a unique plater on the markets in Europe, Middle East and Africa (EMEA).

“All these acknowledgements, together with the capability to provide skills, experience, accuracy and consistency in every project or aspect of production (from the design of the single part to the delivery service), have contributed to Growermetal setting a whole new standard in the automotive industry,” points out Paolo.

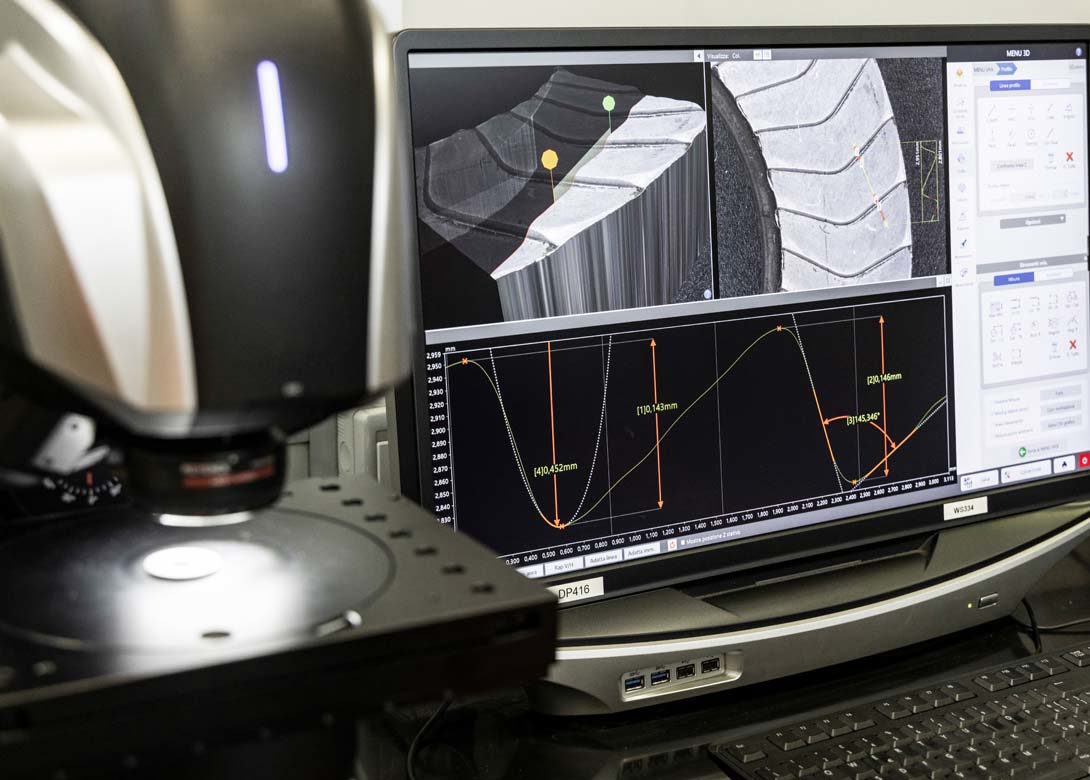

One final aspect that helps Growermetal stand out as a state-of-the-art fastening system is its ability to work with customers on specific requests. “Being able to work alongside customers and develop innovative solutions is what truly puts Growermetal’s about the rest,” states Paolo proudly. “Our production includes a constantly evolving range of washers, with the opportunity to manufacture special items according to customer’s drawing – thanks to a R&D team of high-qualified technicians.”

Discovering the complete range for automotive applications

Growermetal will showcasing its authority as an automotive industry supply at IZB, the European leading trade fair for suppliers of the automotive industry, which will take place in Wolfsburg, Germany, from 11th – 13th October 2022. At the show the company will display its wide range of fastening solutions and products to all customers and visitors, including some of its flagship washers and parts, which includes:

The ultimate washer solutions

In addition to the wide portfolio of standard products, Growermetal has invested in its R&D department, in order to develop and design cutting-edge fastening systems. The ultimate products developed by the company’s experts include special blanked and bended parts, high thickness and precision flat washers, EPDM and plastics moulded pieces and parts with glued EPDM inserts.

Special shaped blanked and bended parts

Thanks to its in-house process and our experienced technicians, Growermetal designs, manufactures and engineers shaped blanked and bended items, according to customer’s specifications and drawing. This allows the maximum customisation of every part produced, creating the most suitable blanked and bended parts.

High thickness and precision flat washers

Among the latest products introduced in the Growermetal washers family, there are high thickness and precision flat washers – special products engineered and manufactured by the company according to customer’s technical specifications and drawing, to guarantee the best performance for different applications. These items are particularly suitable and widely used in the automotive industry and represent the most recent example of Growermetal research.

EPDM moulded part projects and parts with glued EPDM inserts

EPDM (Ethylene Propylene Diene Monomer) is a popular elastomer that offers a superior resistance to extreme outdoor conditions. Thanks to a composition developed with a sulfur or peroxide cure system, EPDM compounds show a great resistance to high temperature and an improved compression performance. Due to these characteristics and benefits, the company develops and designs moulded part projects where the washer and the EPDM part are co-stamped. In order to complete this new product range Growermetal can also manufacture with, when feasible, the EPDM inserts glued onto the metal piece. The gluing of EPDM inserts is carried out completely in-house, thanks to the latest cutting-edge engineering robotic technology.

“Accuracy, consistency, flexibility are the main values of the assortment of automotive washers, which are the true expression of the company’s goal to fulfill the present and future needs of the industry – meeting automotive manufacturers’ expectations,” concludes Paolo. “This is a continuous evolution that is guided by experience and boosted by innovation, shaped to face every challenge.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.