DELO Industrial Adhesives has launched the DELO MONOPOX HT2999 adhesive with exceptionally high temperature stability, developed primarily for the automotive industry and mechanical engineering.

High temperature resistant adhesives are in particular demand for electric motors and power electronics, as many products that are currently on the market show a clear drop in performance at temperatures above 150°C. DELO points out its new structural adhesive can be used above that temperature.

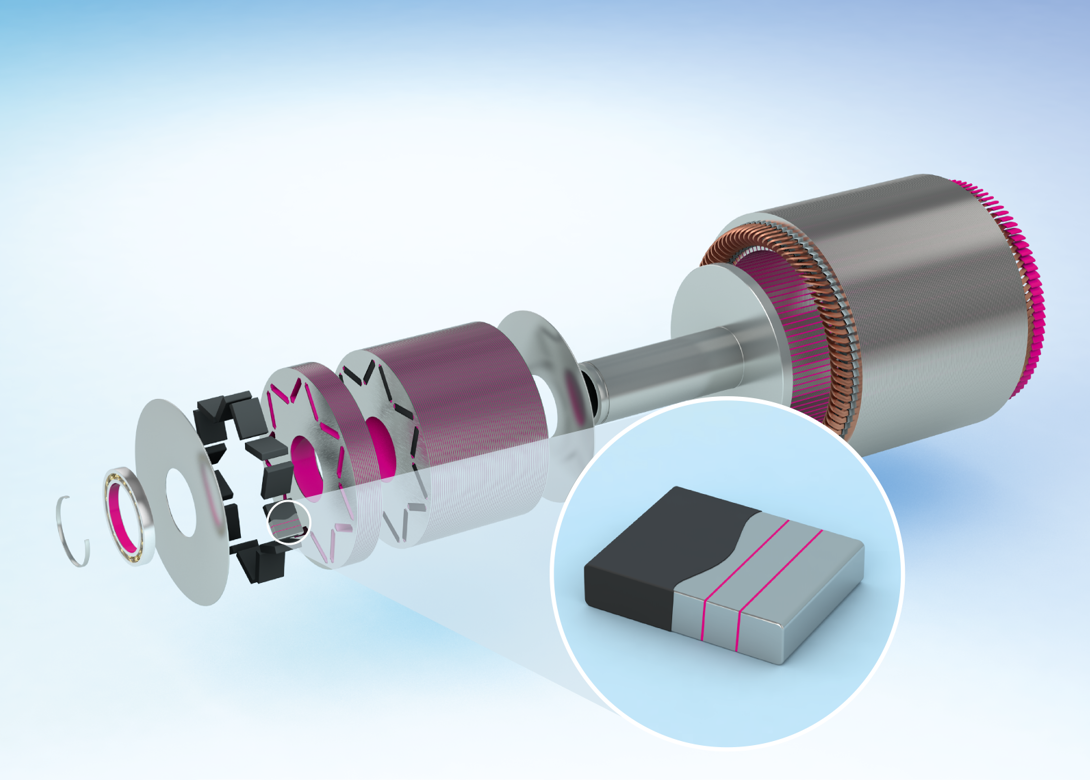

DELO’s MONOPOX HT2999 performance profile has been optimised for bonding magnets in electric motors. For example, the compression shear strength of bonded magnets (NdFeB) is 20MPa at 180°C, with the bonded joints remaining thermally stable in the long-term. Even after 1,0000 hours of storage at 180°C they achieve a temperature stability of 20MPa.

The maximum operating temperature of electric motors is generally 180°C since the powerful rare earth magnets will demagnetise at higher temperatures. If a certain application requires resistance at higher temperatures, DELO MONOPOX HT2999 can even be used up to 220°C.

Electrical insulation is another important property of the adhesive. It minimises eddy currents in electric motors, reducing heat development and increasing motor performance. DELO MONOPOX HT2999 is additionally provided with integrated spacers to ensure a uniform and very thin bonding gap of 50µm for magnet stacking. This allows the use of more magnetic material and also contributes to motor efficiency.

The one component epoxy resin is grey and pasty and takes just 10 minutes to cure in an air convection oven at 150°C, which is a time saving when compared to other high temperature adhesives that require 30 to 40 minutes curing time at 150°C.

“Four times the strength of the previous generation is a truly extraordinary step in development. The product is also electrically insulating and provides additional functionalities for manufacturers of electric motors,” says Dr Karl Bitzer, head of product management at DELO. “It's a good example of how we're pushing the boundaries of what's technically possible, step by step.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.