Vehicle development and the lowering of fuel consumption means that cars now need to be made lighter without losing any stability. This can be achieved either by using new materials or by reconstructing existing parts in a way that retains their functionality. However, the challenge of making lightweight components is becoming more challenging, with every gram counting.

By Reinhard Bührer, head of marketing and sales (member of the management board), Hatebur Metalforming Equipment Ltd

Trends in the automotive market and in production

The production and sale of passenger vehicles is set to increase by approximately 3.4% a year (source: DC Advisory, October 2014), with production sites following the markets. China, NAFTA and Europe will continue to be the biggest markets, with the highest growth rates expected in the small vehicles sector.

The automotive industry’s primary objective is to reduce CO2 emissions. By using innovative forged components made of steel it is possible to create a lightweight construction that can demonstrably reduce energy consumption and CO2 emissions. For example, fitting a passenger vehicle that has a 2 litre turbo diesel engine, dual-clutch transmission and four-wheel drive, with a lightweight drive and chassis can reduce its weight by up to 42kg.

How can this be achieved?

The focus of reducing the weight of forged components lies on the following two points:

• Creating a lightweight construction by using new and improved grades of steel (e.g with a high strength of Rm > 550N/mm2, using specific grades of steel for heat treatment from the forming process).

• Creating advanced geometries for the forged components (reducing the amount of material in non-functional areas of the component, asymmetric shapes, reducing wall thicknesses).

Effect on production

As you might expect, reducing the weight of forged components has a huge effect on how they are produced. The design of the tools needs to be modified; the way in which the components are handled needs to be changed; and the cooling process must be redefined.

The influence of lightweight construction will most definitely be felt in the forming industry, whether it is the result of new and improved grades of steel or the use of complex, asymmetric component shapes and their geometries. The trend will lead to an increase in the amount of tool and process support needed at the machine.

Process simulation assists customers with lightweight components

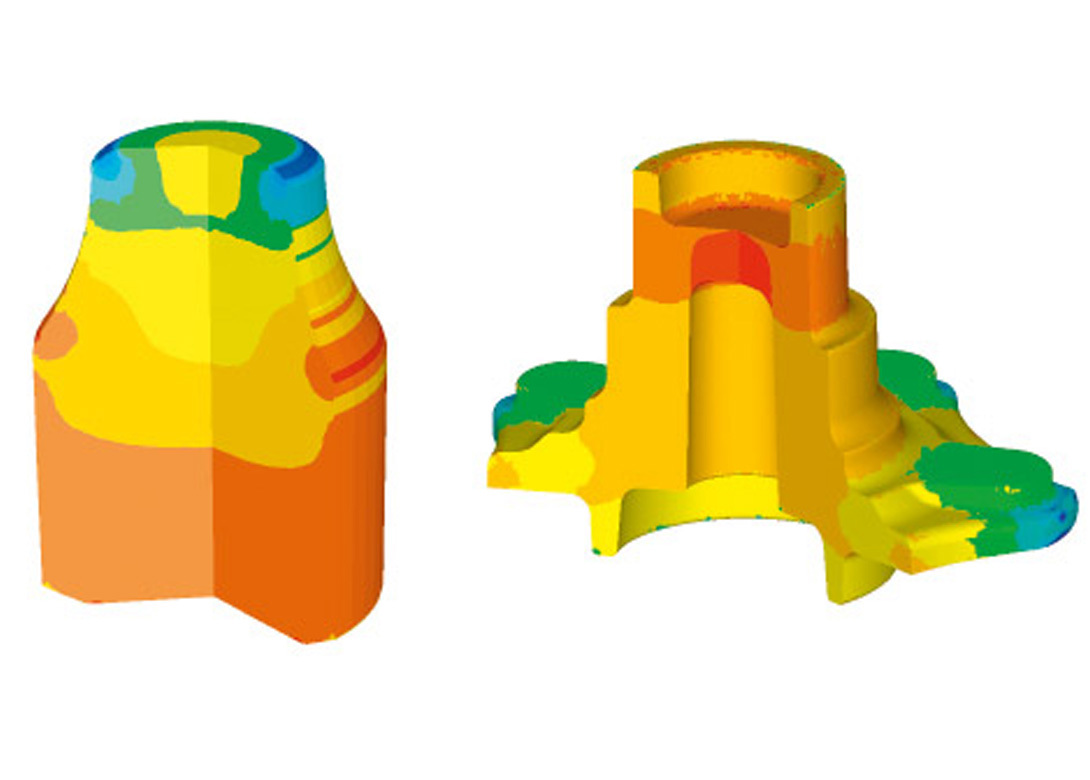

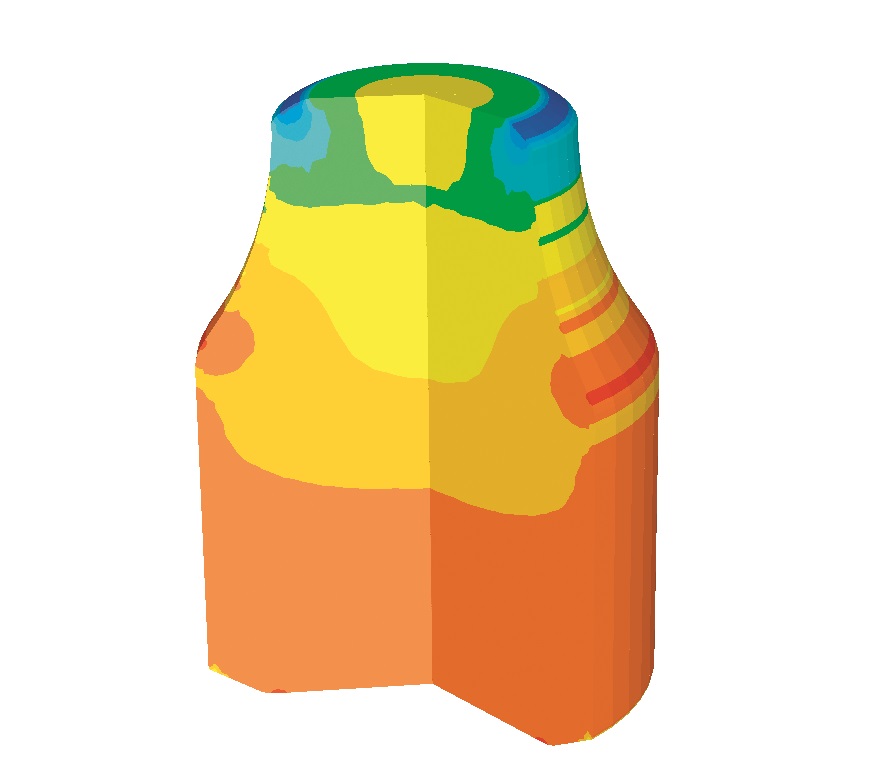

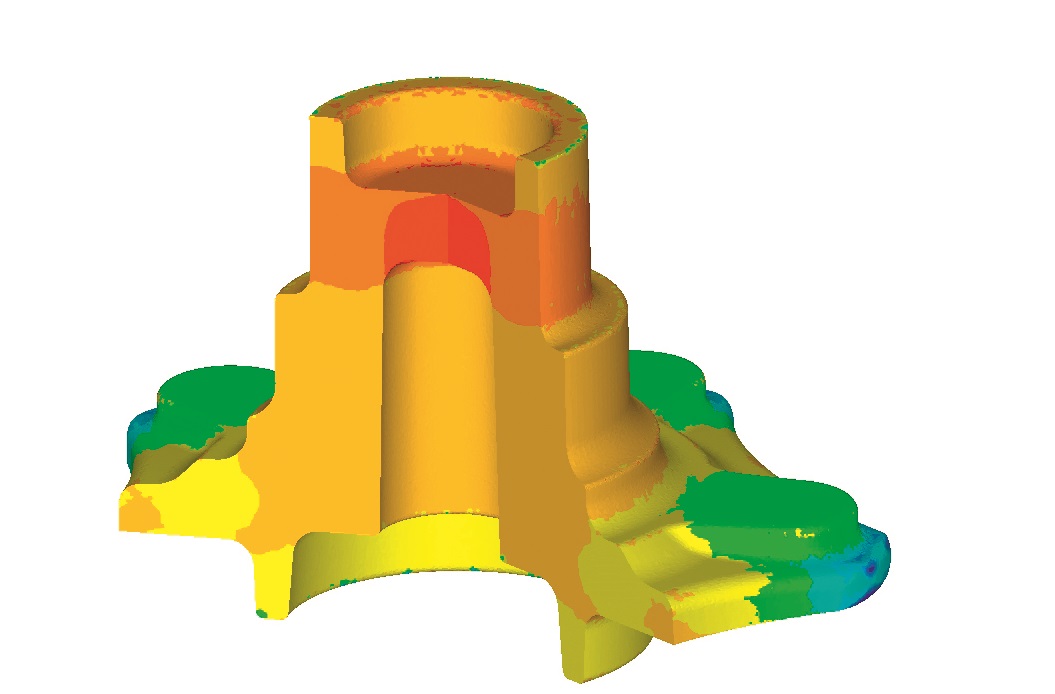

Customers can rely on professional assistance from Hatebur in precisely this area. Hatebur first launched the FORGE program back in 1999. The combination of this tool and the company’s experience enables us to satisfy customers’ ever-increasing demands regarding production complexity and quality.

Collaboration begins with meticulous analysis of the components. The simulation checks potential part shapes in order to ensure a cost-effective design for the forging process and the longest possible service life for the tools.

The longer the service life of the tools, the shorter the machine downtimes and, consequently, the lower the cost of manufacturing the components.

Also, the earlier Hatebur is involved in the manufacture of components, the better the forging process can be designed. This will help customers manufacture parts that reduce weight as well as lower costs.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.