Whether it is about joining sheet metal with sheet metal, sheet metal with plastic, or sheet metal with fiberglass, KVT Fastening insists its new POP® VGrip™ blind rivet is the ideal solution when it comes to fastening with only one side access.

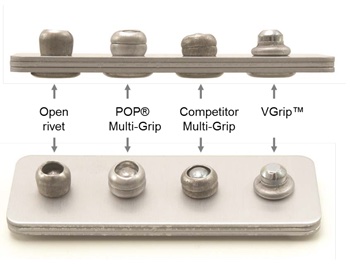

POP® VGrip™ differs from the standard multi-grip rivet with its big closing head which forms in high consistency, fits well for large hole tolerance, provides high security against pull through, and reduces surface pressure.

A feature of the VGrip™ blind rivet is the closing head design. During the setting process, the sleeve material is moved radially outwards, resulting in a disc shaped closing head. In addition, the mandrel head does not dip into the rivet sleeve, a can occur with conventional multi-range blind rivets.

This feature enables the POP® VGrip™ to distribute tensile forces over a larger area on the side of the closing head. As a result, KVT says VGrip™ can absorb higher tensile forces than a conventional multi-grip rivet. Additionally, due to the greater load distribution, thinner or fragile sheets can be fastened to the closing head side or blindside without damaging or deforming them.

Conventional blind rivets are designed to cover a small specific grip range of components to be joined. For example, four different blind rivets with different grip ranges must be used for different application thicknesses from 1.5mm - 6mm. To reduce this complexity, the POP® VGrip™ allows a grip range from 1.5mm - 6mm to be processed with only one rivet. Thus, four different rivet types are replaced by one type of rivet and the stock keeping unit (SKU) in stock management can be reduced.

The loose remaining mandrel in the product reduces the product value due to the rattling and also creates a potential safety issue when it falls within the application. With the mandrel geometry of POP® VGrip™, the mandrel can be locked and prevented from rattling within the application or falling out.

Apart from the standard type of the multi-grip blind rivet, POP® VGrip™ offers flexibility for customisation. KVT states it can be customised for plastic and composites. Compared to the conventional blind rivet, the expansion control of POP® VGrip™ is achieved by crimping the rivet body at a specifically defined area and thus reducing the radial load on the borehole. This is suitable for plastic and composites material.

Secondly, POP® VGrip™ offers a high strength structural blind rivet solution. This variant results in an increase in tensile and shear forces. The remaining mandrel is in the shear zone and is bearing the load.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.