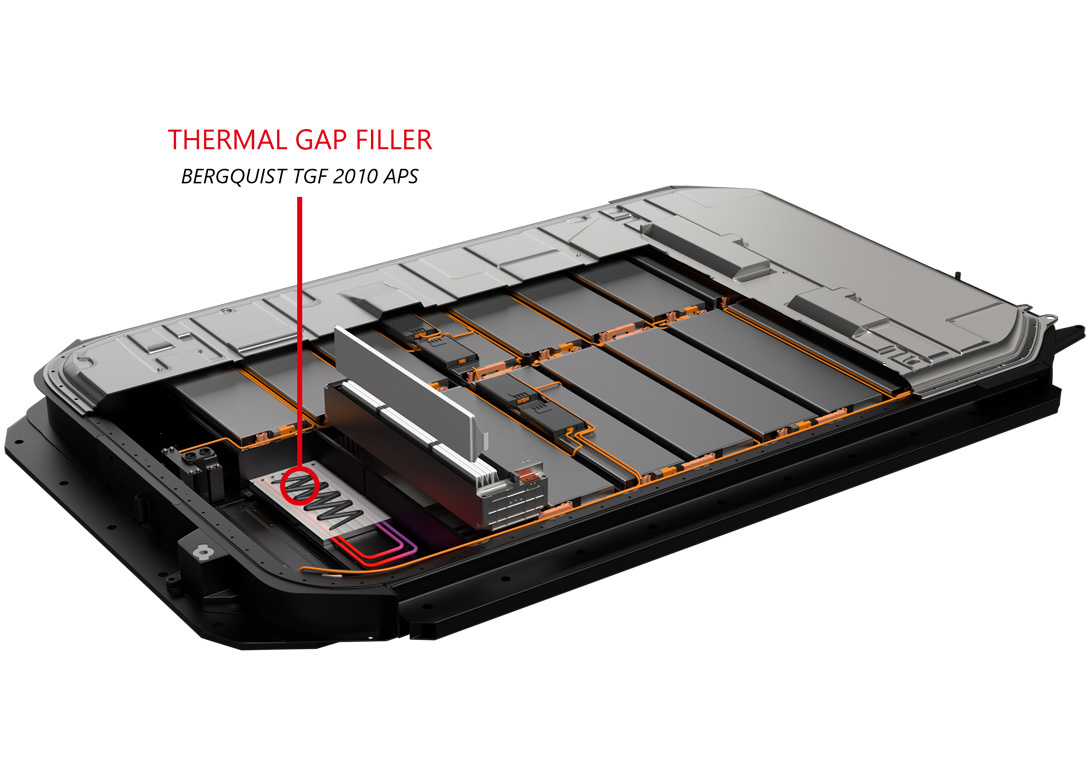

Designed to increase the efficiency of electric vehicle (EV) batteries, Henkel has released its new product, Bergquist TGF 2010 APS, a silicone-free, fast dispensable battery thermal management solution.

With the rapid growth in the EV market, manufacturers are seeking new ways to manufacture better and safer batteries that manage thermal risks, while also increasing production efficiency and cost. With its new battery solution, Henkel Adhesive Technologies aims to meet these objectives.

“The fast-growing development towards zero-emissions mobility, especially e-mobility, is requiring steady innovation to meet demands in this field. These large market potentials are fuelling Henkel’s effort to expand our portfolio of e-mobility solutions even further, especially pushing forward in the field of thermal interface materials,” says Stephan Hoefer, global market strategy head for e-mobility at Henkel.

Henkel’s new product is a two part, silicone-free, liquid gap filler. Henkel states the thermal gap filler solution helps to extend the life of automotive batteries through its heat dissipation qualities, while also helping customers manufacture battery packs faster and optimise their equipment maintenance costs. Thanks to its silicone-free formulation, the risks of silicon outgassing are avoided, thereby preventing negative impacts to electrical contacts or to pre-painted surfaces.

With a high dispense rate of 80cc per second and an application time of approximately 60 seconds, one OEM has confirmed that the new solution has enabled the manufacture of 800 battery packs a day on a single production line. When deployed, Bergquist TGF 2010 APS provides a thermal conductivity of 2.0W/mK, allowing for heat dissipation. The optimised filler package with low abrasion characteristics helps to reduce maintenance work and wear of dispense equipment. Also, the low squeeze flow of the material enables a fast assembly of the battery modules, keeping cycle times at a high level.

“For us at Henkel, it is essential that our products and solutions meet the needs of our customers as best as possible. For that, we build on our know how and technologies as well as our close relationships along the entire value chain. The Bergquist TGF 2010 APS was developed to reflect customer demands in battery gap fillers and shows how Henkel supports with the right setup for mass production, utilising our global partner network of dispensing equipment suppliers,” explains Marvin Romberg, e-mobility business development manager EIMEA at Henkel.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.