Henkel has launched a high performing boron-free cleaner to be used during the metal pretreatment process for aluminium vehicle components in order to meet corrosion and adhesion performance without the use of boron.

Traditional aluminium cleaners rely on boron to help reduce the potential for aluminium etching during the automotive cleaning process. Etching can prevent the creation of high-quality automotive part components – contributing to unnecessary scrap generation. Henkel’s Bonderite C-AK 14415 eliminates the use of boron, while continuing to provide high cleaning power and a low etching effect.

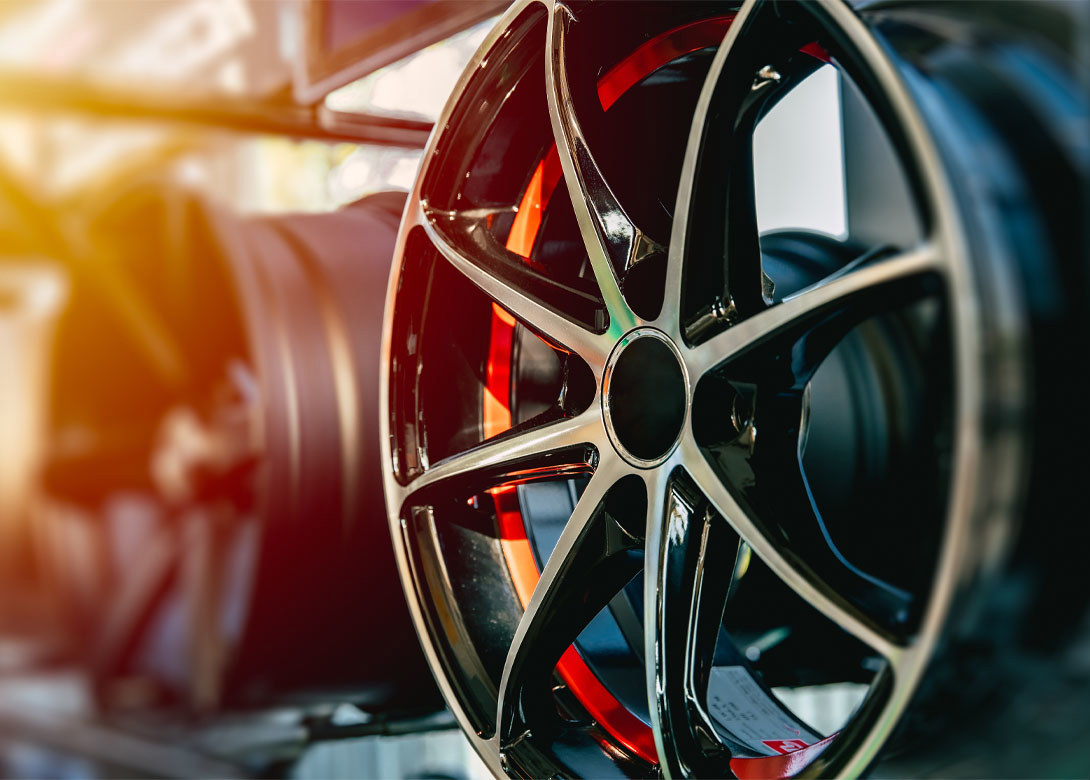

Suited for aluminium automotive components, such as aluminium wheels and aluminium battery housings, the technology meets most automotive OEM requirements. As a one-component technology, Bonderite C-AK 14415 improves process efficiency, as well as safety and handling during the manufacturing process.

“Bonderite C-AK 14415 is another example of Henkel’s commitment to providing solutions that are sustainable and deliver high performance,” said Kathrin Schaeuble, manager PD surface treatment and cleaners at Henkel. “It’s a great example of how we continue to make a positive impact across the value chain, from product development through production.”

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.