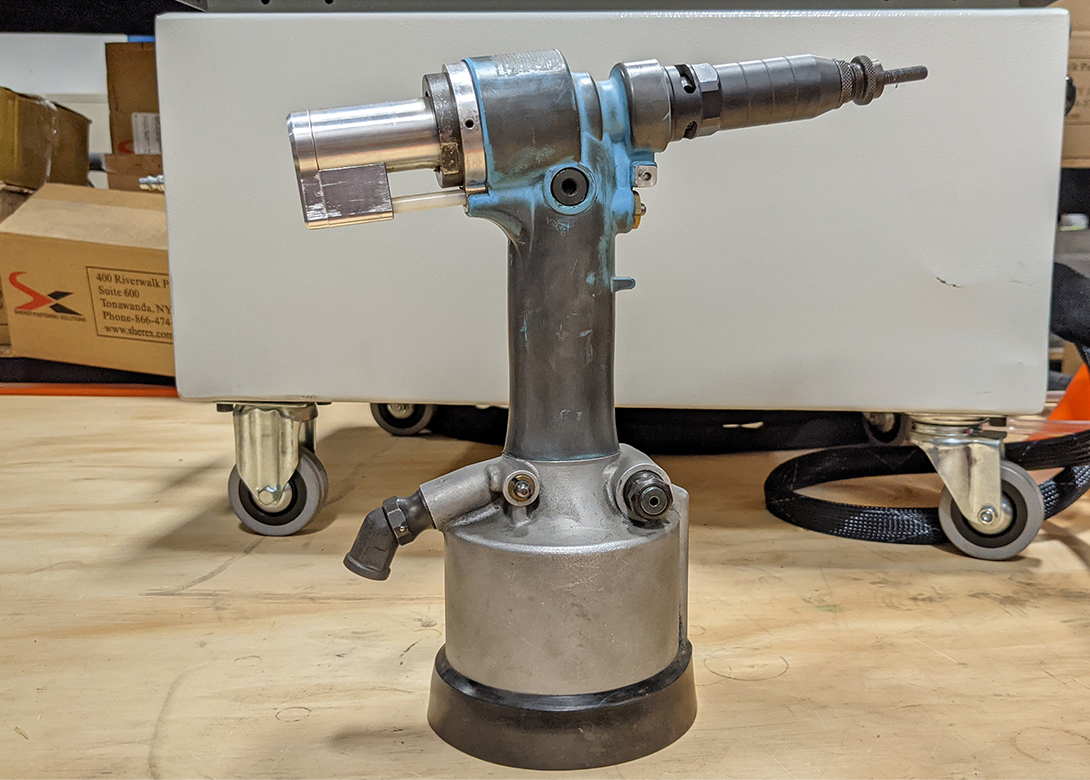

A first generation FLEX-5 rivet nut tool, used to install Sherex rivet nut studs was recently found to still be in use in a construction, military and heavy-duty truck fabricator assembly line, twelve years later. Here, Sherex Fastening Solutions outlines a few easy steps to ensure a long-lasting tool.

Bought from Sherex Fastening Solutions in 2009, the FLEX-5 tool is still installing rivet nuts, which is possible, says Sherex due to some good maintenance. “These older FLEX-5’s hold up really well with just some basic care,” commented Engineering Technician at Sherex, Mike. “Basic care of hydro-pnuematic rivet nut tools is really important to their durability, as well as a few easy steps to ensure a long-lasting tool.”

These steps include if the air supply is not equipped with lubricator before use, squeezing a few drops of light lubricating oil on the tool air inlet, as well as high friction locations such as spindle housing, should be regreased with a high speed, high temperature grease. Every 500,000 cycles the tool should also be completely checked and parts that are worn or damaged should be replaced. O-rings should also be replaced and lubricated with Molykote® 55M grease or equivalent before assembly.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.