When designing a new project, manufacturers in many cases will focus on 'high value' components, however the importance of specifying the correct fasteners for the type of application can be of great importance. Weight, cost, ease of installation and product standardisation are key features for manufacturers to consider, increasing the need for them to involve a business with expertise in fasteners.

Ian Carvell, European engineering director at Optimas, explores the benefits a fastener expert can deliver to OEMs and tier suppliers.

Design engineers could be forgiven for overlooking the humble fastener, considering the huge number of considerations that come into play when introducing an entirely new project. The competitive nature of the modern market place drives the engineering focus towards innovative technologies.

There is very little perceived public interest in how a fastener has aided in the final performance or design aesthetic of the latest consumer product. Very few people will walk into a car showroom and ask if their potential new purchase will include aluminium fasteners instead of steel. Even in the industrial world customers are more interested in headline figures than the gritty details.

Why should designers care?

The truth is, well optimised fastener selection can offer many tangible benefits: both to manufacturer and end-user. Sticking with the example of automotive design, fastener choice is as relevant to a supercar as it is to an off-road construction vehicle or your daily driver - but in entirely different ways. Focussing on fasteners can be a route to profitability and clarity of purpose for manufacturers.

What are the main benefits of effective fastener specification?

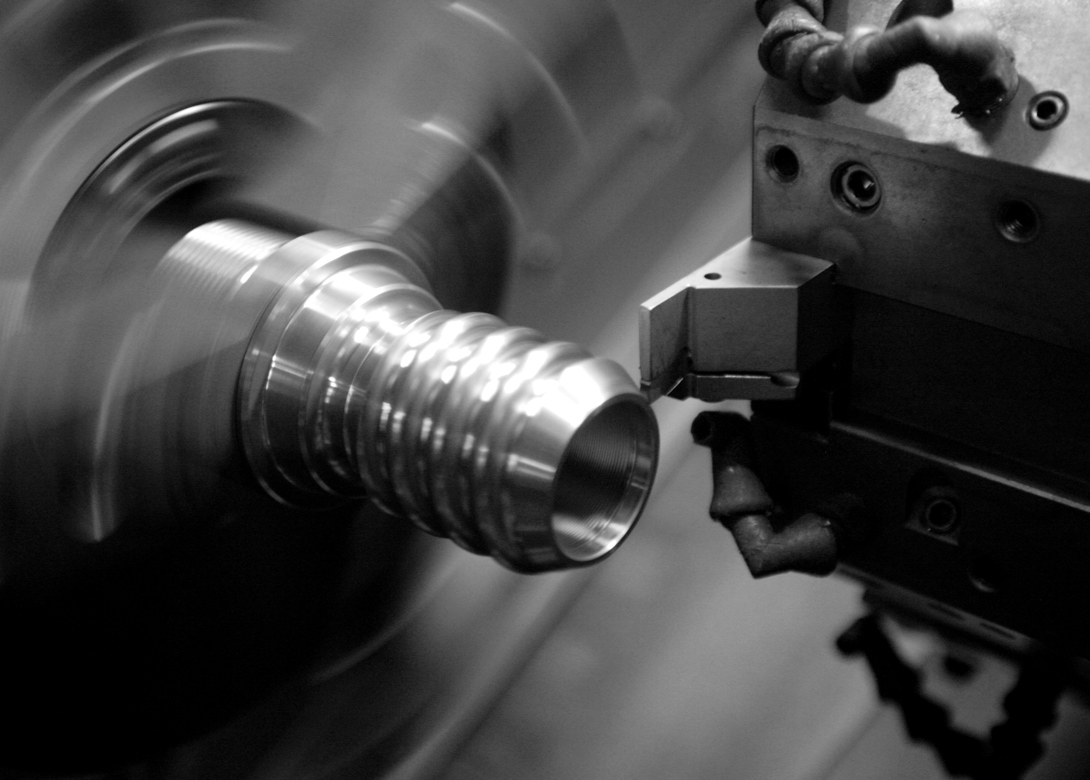

For most applications across various industries it is the benefit of product standardisation. Why specify a custom manufactured 11 mm bolt for one fixing and a 9 mm bolt for another when you could use a single 10 mm solution for both that is freely available and achieves the same purpose? It might be quicker to design these components than trawl a standard parts list during design, but this saving will quickly be eliminated when production starts.

Optimas engineers have worked with customers to reduce part counts by as much as 40% during the design phase. Over an entire development process and production run, standardisation offers huge cost savings.

Another benefit is weight. Selecting aluminium components over steel may only equate to savings of a few grams on a single part, but in many hi-tech industries such marginal gains could represent a distinct advantage over the competition.

Ease of installation of fasteners should also be considered as it can make a notable improvement to production line efficiency. Correct specification of fasteners can mean a reduction in bins, and also clearer definition of what should go where. When production line personnel are installing thousands of these components every day on multiple units, a clear fastener policy leads to speedier installation across the line and, ultimately, improves productivity.

Finally it is a question of cost. Building prototypes, amending design, reaching industry standards and then achieving a finished product before launch deadlines is incredibly capital intensive. As a manufacturer, can you afford to increase this by operating a fastener policy that isn't streamlined? In most cases it's a no, so taking an integrated and involved approach to what fasteners you specify can minimise the financial impact.

How can a manufacturer implement these benefits into their design?

The first step is recognising where you could benefit from the support of experts. From the earliest design stages you should work with a supply chain manager who is able to offer engineering expertise and understands which benefits are of most importance to your application.

Reaching the nirvana of fastener specification requires a tailor made approach that is based on each individual application. The best way to achieve this is to involve a fastener expert from the initial design phase of a project, so that fastener engineers can become familiar with your application and its specific demands. The earlier that a partner such as Optimas becomes involved, the more ingrained the performance benefits will be with your design.

As a designer or manufacturer, fasteners can offer great benefits to all stages of development and manufacture if the optimised approach is applied. As with many things in life, finding the right bolt hole can be a real life saver.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.