SPIROL invented the coiled spring pin in 1948 and has manufactured the product at its UK plant for the last forty years. A decade ago the Corby plant primarily supplied the domestic market but recognised it needed to actively project its offer to the whole of Europe. Executive Editor Phil Matten made a return visit to hear from European Managing Director Andrew Freeman on how the business has developed.

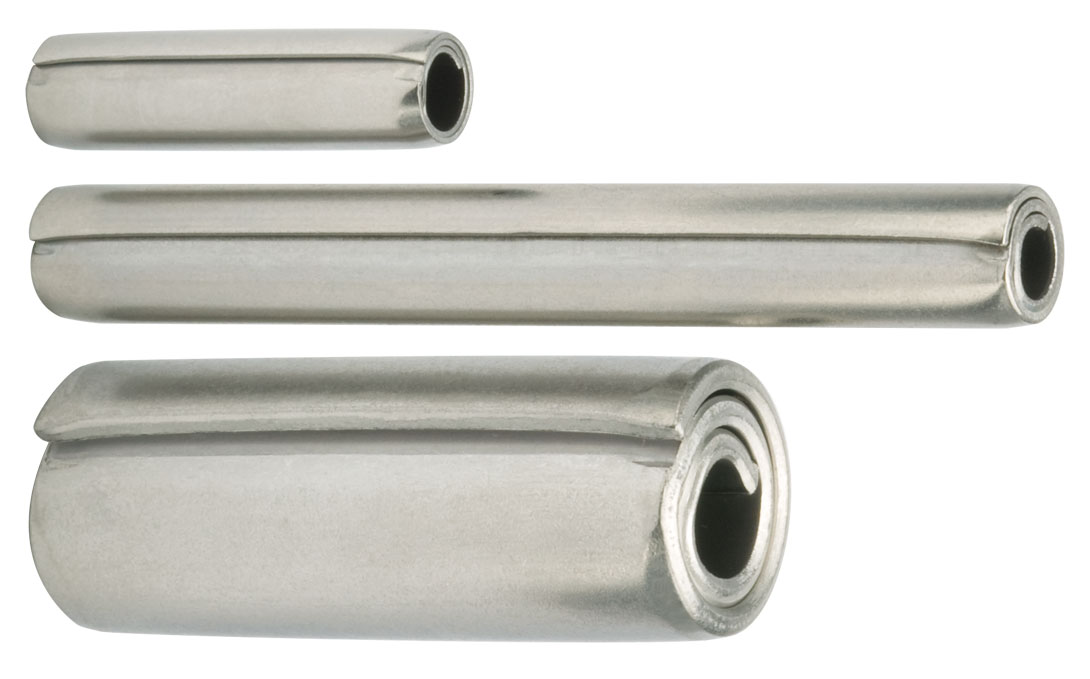

Immediately recognisable for its two and a quarter coil cross section, coiled pins are self-retaining pins that compress when installed into the host component, uniquely retaining uniform strength and flexibility after insertion. Applications are ubiquitous, ranging from aerospace and automotive, through heavy equipment to electronics, consumer durable products and cosmetic dispensers, locks and latches, medical equipment and window/door hardware.

With a global manufacturing and distribution footprint, SPIROL also manufactures slotted spring pins and solid pins, rolled tubular components, hollow and spring dowels, spacers and shims, compression limiters and inserts for plastics.

What really differentiates SPIROL is its dedication to application engineering combined with a long-standing commitment to standardisation. SPIROL successfully brings to bear massive experience in application engineering from across its diverse markets, through a network of sales engineers, located throughout Europe, and in direct contact with OEM designers and production management.

Committed to constantly enhancing its customers’ competitiveness, SPIROL also remains adamant that standardisation is fundamental. It lowers material, tooling and production costs, delivering best value to the majority of customers able to take advantage, through the intelligent guidance of those sales engineers, of SPIROL’s standard production and stock ranges. Where specials are required for unique applications, production and range standardisation provides the platform to produce them more cost-effectively.

“Having the most extensive standard range in the market is a major advantage,” explains Andrew Freeman, “where demand is less predictable or where users are being serviced through distribution partners. While 60% of our output goes to automotive, from a wide range of other markets we see little or no scheduling of requirements.”

SPIROL’s step across the Channel was a small distribution operation in Reims to develop the French market. “We recognised that continuing to focus primarily on the UK domestic market would, at best, severely limit our growth and capability to invest, and potentially mean we were no longer even here. Having succeeded in France, we developed into Germany and then to the whole of Europe.”

The French distribution centre has consequently expanded to around 1,200m2 – which in terms of SPIROL product means a major stockholding. “We also hold substantial inventory here in Corby, both for scheduled orders and for general availability,” says Andrew. “Unfashionable as inventory holding might seem these days, it makes SPIROL uniquely responsive.”

SPIROL manufactures at different sites across the world. “Inserts for plastics are made in Mexico. Our Ohio plant manufactures shims, a range which we introduced here a couple of years ago and which is growing really well. In general the plants in the USA and Canada produce similar ranges to the UK but focus primarily on the North American market.”

Andrew continues: “Crucially, our sales engineers work closely with designers in Europe and North America, while our global distribution capabilities, including a location in Shanghai, means SPIROL can follow through with direct supply to the OEM assembly operation wherever it is located.”

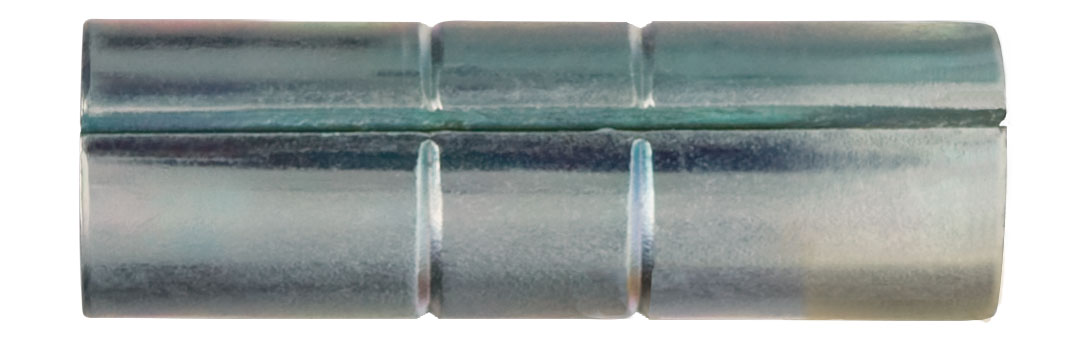

Vehicle lightweighting and the general adoption of plastics in other applications has brought two SPIROL ranges to the growth forefront. “As the usage of plastics has expanded, compression limiters have become an increasingly significant product for us, here in Corby and globally. Again, standardisation distinguishes us in the market, cutting the risks for the customer by eliminating the need for expensive bespoke tooling or end of life agreements. Applying our engineering knowledge means we can assure a designer that a standard part will perform exactly as needed in their application. Then we can supply anything from a few hundred to millions of parts.” The future growth of electric vehicles also represents an opportunity for SPIROL as the compression limiters are a key component in batteries.

Weight reduction has meant increased demand for shorter parts but that brings the potential for compromised performance and reliability. “Again, our sales engineers join efforts with the designer, and as the pace of model replacement accelerates, and more design is done on the fly, with production management. Our dedicated automation technology team also provides proven installation solutions that can be integrated to the customer’s line.”

“We have now developed a new range of aluminium-based compression limiters, machined to provide greater bite into the plastic. As well as weight reduction and performance, these have the additional benefit for automotive of being lead-free. They are proving a very attractive solution and demand is growing very rapidly now.”

While the Corby plant has unquestionably moved on substantially in ten years, Andrew Freeman is first to acknowledge there is plenty more to do. “We have been putting in around GB£1 million annual investment for equipment,” he says. “That has to be paid for and our sales growth has been crucial.” There has been specific investment in heavier duty production machinery and in secondary operations, particularly heat treatment. Corby’s quench and temper line and annealing furnace were recently converted to mains gas supply for greater cost-efficiency. The lines have also seen many small but significant improvements in product handling to enhance productivity. “Heat treatment is a core quality discipline for our product types, so it is crucial we exercise direct control over it.”

One process is unavoidably sub-contracted – surface coating. This presents a risk of parts contamination, which in a ‘zero-defect’ world is anathema. Hence, SPIROL has continuously invested in improving its inbound parts inspection capabilities.

Many other changes are subtle – reflecting a very clear commitment to a continuous improvement ethos. “We benefit hugely from the accumulated knowledge of our workforce,” says Andrew. “However, while material cost increases, such as we are experiencing currently, are by and large understood by our customers, the expectation now is that other cost increases will be covered by improvements in our efficiency. That means a carefully orchestrated series of incremental improvements, the success of which is as much based on our established workforce buying into the benefit of the changes. Increasingly our culture recognises that the operator doing the job is most likely to identify and recommend those improvements.”

“In common with most British manufacturing businesses, our history included periods of minimal investment or recruitment. We are committed to bridging that skills gap through an active apprenticeship programme, to ensure continuity and the talent base on which we can continue to grow.”

Andrew Freeman believes the long-standing UK aversion to working in manufacturing may at long last be turning. One recent recruit, came from retail management – preferring the stability of production work to the family impact of a zero-hour contract and unsociable working hours. “The UK still needs to do a much better job of selling the attractions of a career in manufacturing to young people in schools and colleges. We need people with the manual aptitude to understand the basis of tool making and mechanical processes – but we also need those people to have the intelligence and motivation to look at a problem, work out a solution and contribute effectively to our continuous improvement.”

How does Andrew Freeman feel about BREXIT? “I would have preferred to stay in and achieve change but, as always in business, we have to work from where we are. The short-term weakness of Sterling undoubtedly helped our exports. In ten years’ time, maybe we can look back and see it was the best thing for UK manufacturing, but right now uncertainty is the biggest concern. We need a much clearer understanding of the final relationship with the EU so businesses can plan. Meanwhile, we will continue to focus on sharpening our efficiency and productivity, investing in the equipment and the people, so that we can take maximum advantage of whatever scenario we face.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.