By Dennis Gündel, global product manager zinc flake coatings, Atotech Deutschland GmbH

Successful automotive pioneer Henry Ford knew one thing for sure: “If you always do what you’ve always done, you’ll always get what you’ve always got.” Today, thanks to many innovations and changes, this motto is still key in the automotive industry.

Besides looking to the future and setting major trends, such as introducing alternative drive trains and connected and autonomous vehicles (CAV), the industry has also been taking a closer look at more traditional vehicle manufacturing processes.

Fully automated assembly lines in the automotive manufacturing process repeatedly present new challenges for fastener suppliers. Automotive OEMs prioritise different factors for fixing elements, such as weight reduction (downsizing fasteners), faster screwing (productivity increase), cost optimisation and process reliability in fastening. Reduction of the fastener portfolio is driven by cost pressure and requires coatings that can both be applied universally and work reliably.

Furthermore, they must also be effective in combination with the various materials that can be applied during the automotive engineering process. The coatings must provide the same mounting properties, regardless of whether the fastener is screwed against steel, e-coat or aluminium – materials that are increasingly used in diverse combinations on various internal vehicle components.

Besides the coefficient of friction (CoF) properties that surface finishes on fasteners have to fulfil, additional factors to be taken into consideration include heat loosening requirements and corrosion protection functionalities.

A prime example of where these complex requirements have been successfully met is the latest Daimler specification, MBN 10544. The introduction of this specification coincides with the diversification of various platform strategies and features at OEMs, which will ultimately affect fastener mountings. For this reason, a rationalisation has been implemented to simultaneously increase standardised parts and profitability.

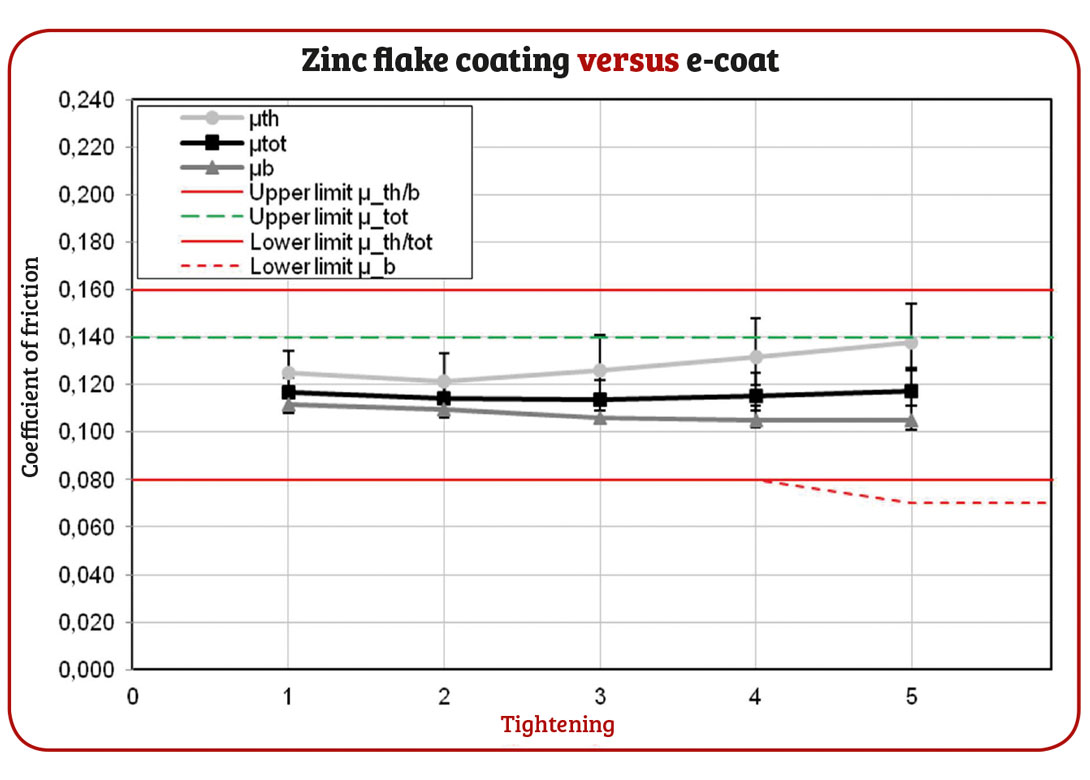

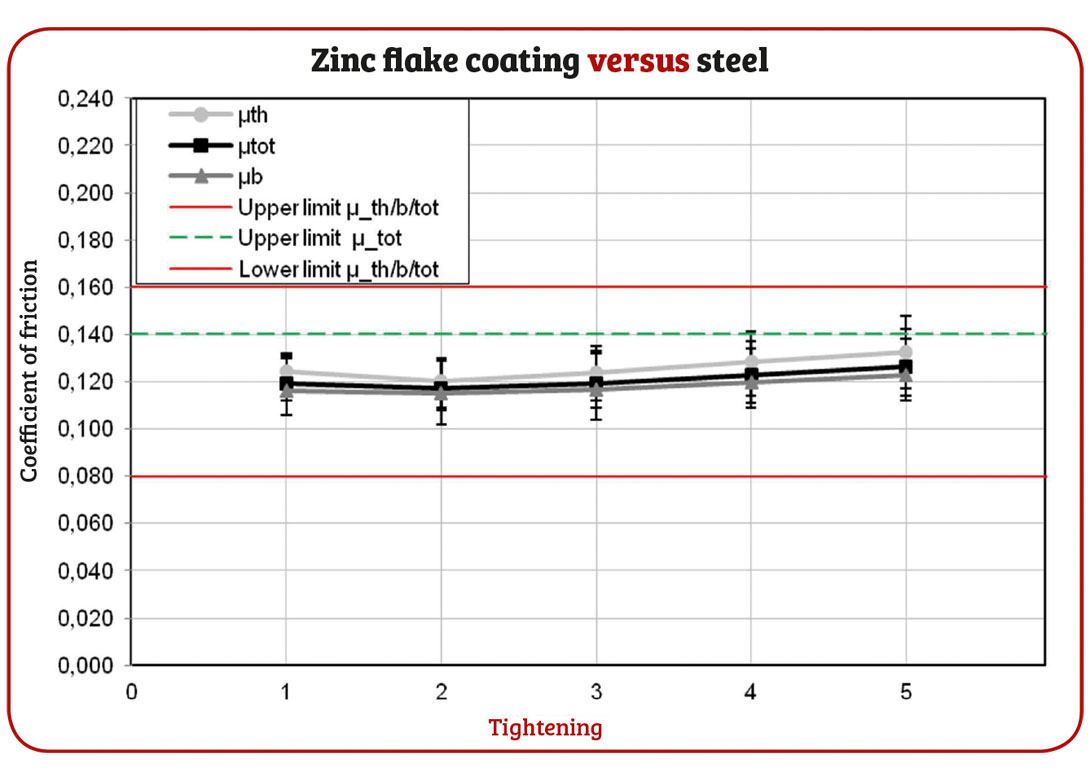

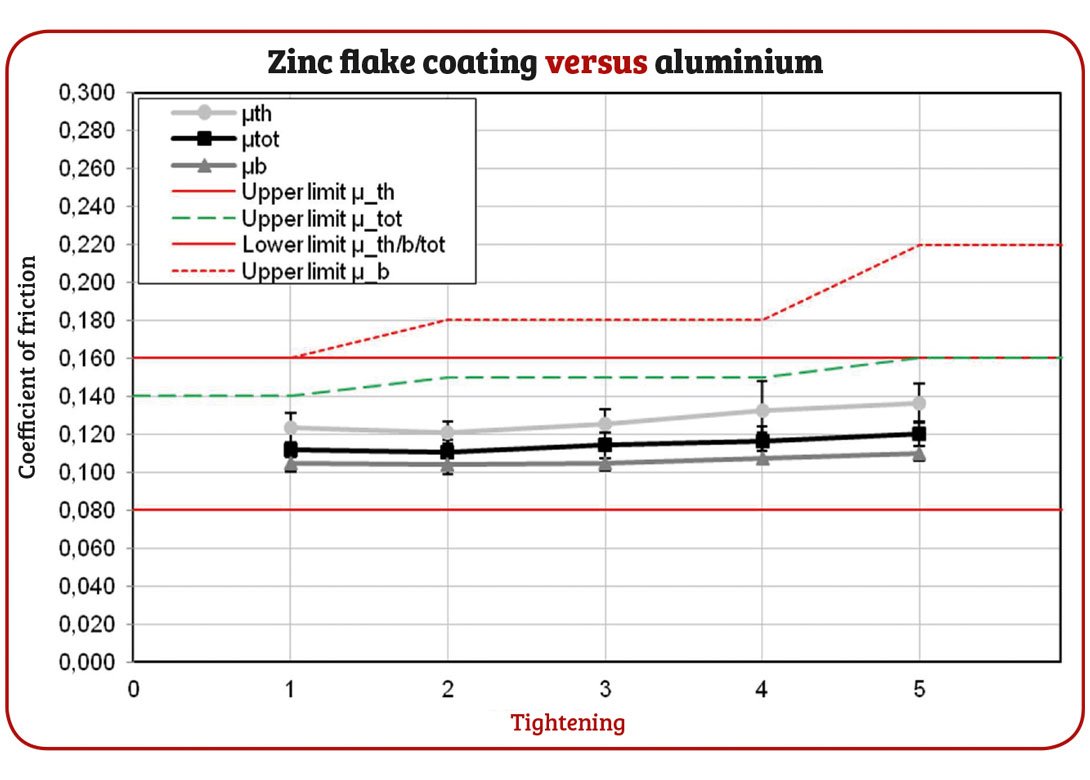

The new test standard defines new requirements for coefficient of friction whereby single values are evaluated – a higher tightening speed is adapted to the latest assembly technologies, multiple mountings for each bolt, as well as new washer materials including steel, e-coat and aluminium.

The standard window for the CoF must be within a narrow range of μtot 0.08 and 0.14. For multiple mountings against different washer materials, Daimler has specified certain CoF ranges that must be met. The demands of the MBN 10544 specification require a single coating system that can be used for a very wide range of Daimler fasteners.

Fig.1: Very low deviation of Zintek® 200 + Zintek® Top LV measured against e-coat, steel and aluminium washer:

After a thorough evaluation, Atotech is now able to provide the perfect zinc flake coating solution: Zintek® 200 + Zintek® Top LV. Atotech’s silver base coat, Zintek 200, is a versatile zinc flake finish that provides excellent cathodic corrosion protection. To fulfil the highly demanding CoF requirements, a sophisticated top coat is essential – the clear finish Zintek Top LV.

This thin layer water-based top coat provides effective additional corrosion protection thanks to its reactive properties. The integrated lubricant ensures that the complex CoF requirements requested by MBN 10544 can be met without difficulty.

The combination of Zintek 200 and Zintek Top LV is a first rate product combination on the automotive market that is also approved for the Volkswagen TL 245 specification and thus also fulfils the equally demanding multiple mounting and heat loosening properties (VW 01131). Furthermore, this system fulfils the requirements of BMW in terms of corrosion protection and CoF behaviour (BMW GS 90100). The zinc flake coating has shown high-quality results in corrosion testing even with prior thermal pre-conditioning for 96 hours at a temperature of 180°C, a process typically required by members of the German Car Association (VDA).

“With the coating system of Zintek 200 and Zintek Top LV, we’re able to provide a leading zinc flake coating system that fulfils the tough requirements of major German automotive OEMs Volkswagen, Daimler and BMW,” states Pascal Poschmann, OEM manager Europe.

“This approach creates synergies and has advantages for both applicators and tiers,” summarises Erwin Gaedt, OEM manager Germany, pleased to have successfully taken on the MBN 10544 project with Daimler. He continues: “Only two products are needed for the big three German OEMs. Atotech could support Daimler with an exceptional coating system that simultaneously helps to simplify their fastener component portfolio.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.